Position adjusting method and device of wheel speed sensor and test equipment thereof

A technology of wheel speed sensor and adjustment method, which is applied in the testing/calibration of speed/acceleration/shock measuring equipment, measuring device, speed/acceleration/shock measurement, etc., which can solve the problem of changing and cannot accurately determine the installation position of the wheel speed sensor , neglect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The position adjustment method, device and testing equipment of the wheel speed sensor according to the present invention will be described below with reference to the accompanying drawings and through embodiments. In the following description, numerous specific details are set forth in order to enable those skilled in the art to fully understand the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without some of these specific details. Instead, it is conceivable to implement the present invention in any combination of the following features and elements, regardless of whether they relate to different embodiments. Accordingly, the various aspects, features, embodiments and advantages below are by way of illustration only and should not be considered as elements or limitations of the claims unless explicitly stated in the claims.

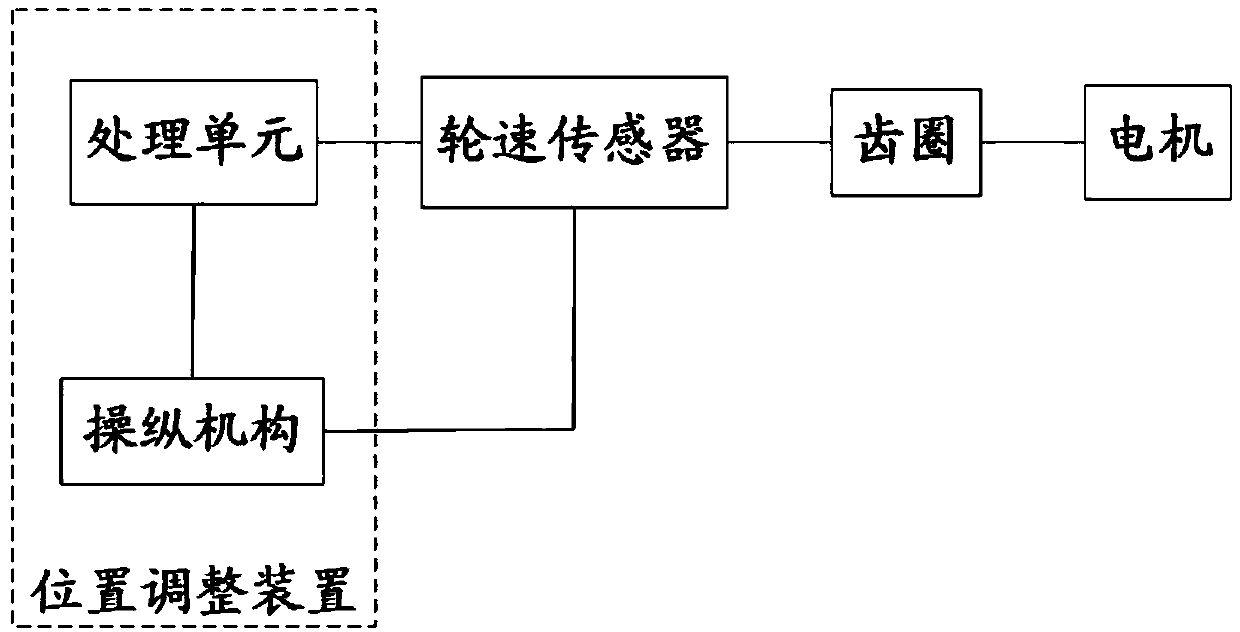

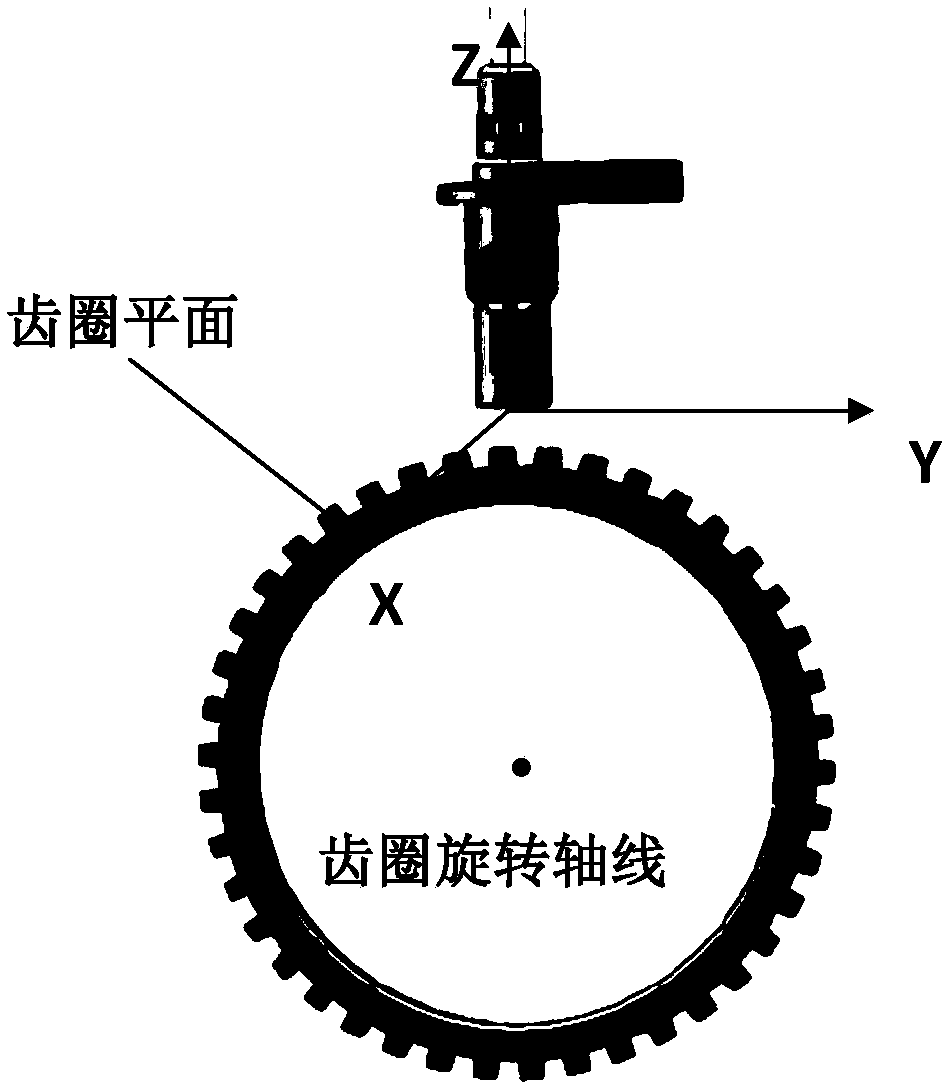

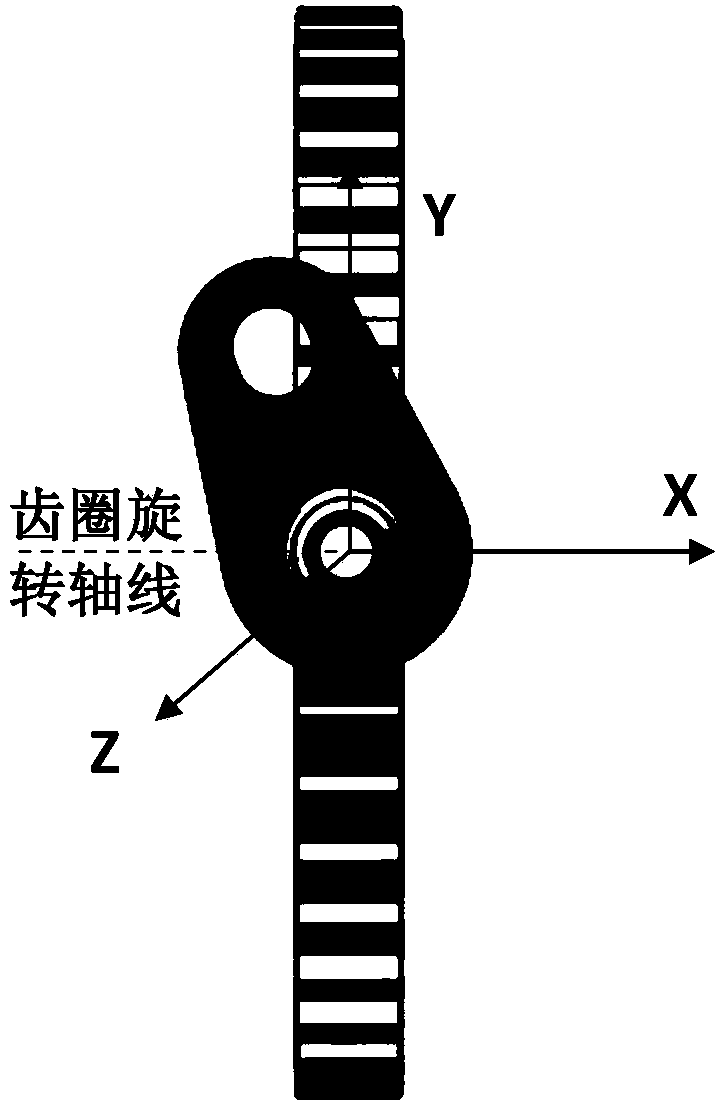

[0037] figure 1 Shows a structural diagram of a wheel speed sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com