Induction heating device

A technology of an induction heating device and an induction heating coil, applied in the field of induction heating devices, can solve the problems of long setup time, difficult transportation, labor and time consuming of the induction heating device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, an embodiment in which the present invention is embodied will be described based on the drawings.

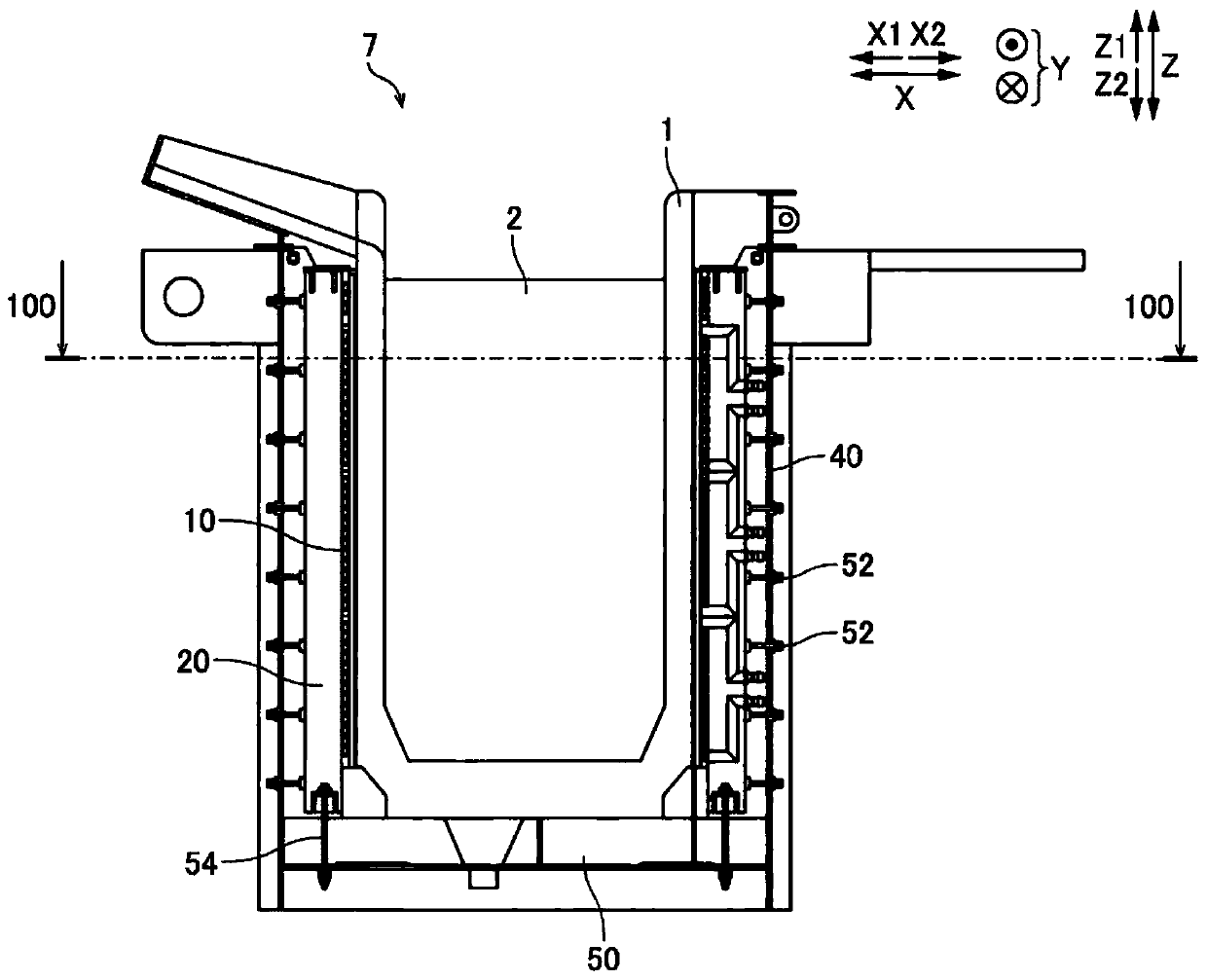

[0032] refer to Figure 1 to Figure 10 The structure of the induction heating apparatus 100 which concerns on one Embodiment of this invention is demonstrated. The induction heating device 100 is used to heat a heat-resistant crucible 1 (refer to image 3 ) of the internal metal material 2 (refer to image 3 ) and a device for melting the metallic material 2 .

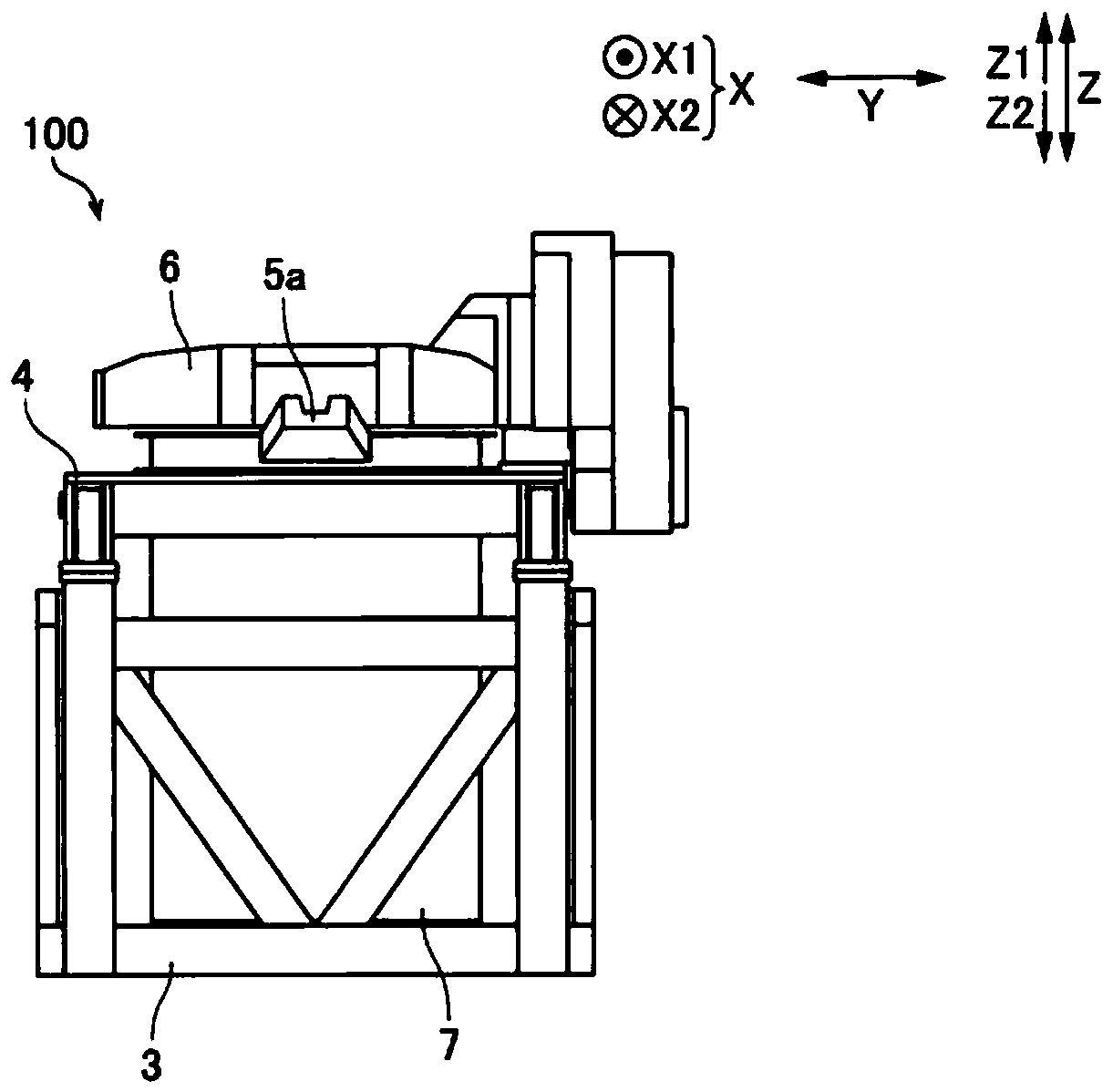

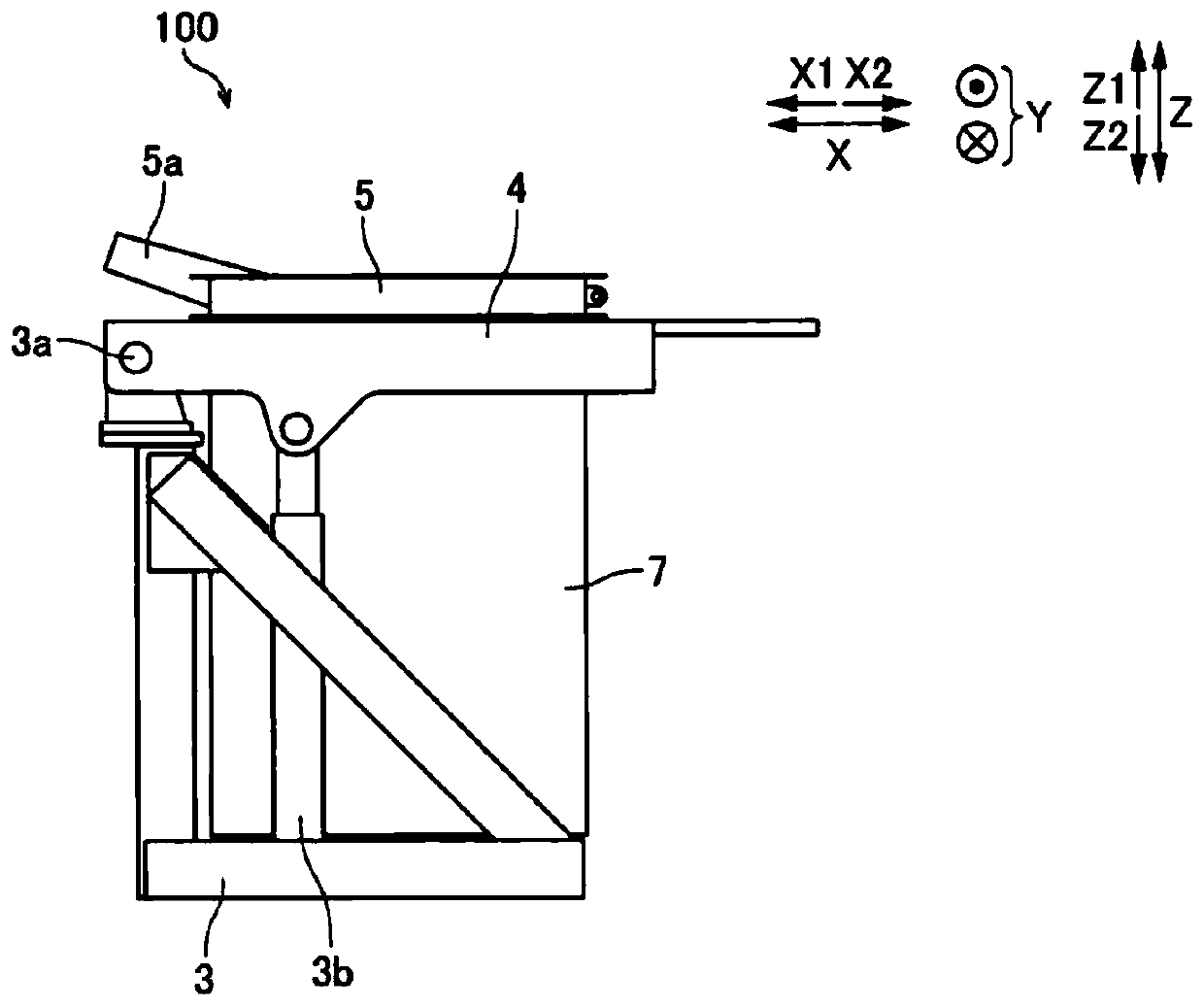

[0033] Such as figure 1 As shown, the induction heating device 100 includes a furnace base 3 , a platform 4 , an upper charging machine (Japanese: upper kasta) 5 , a dust collecting hood 6 , a crucible 1 and a furnace body 7 .

[0034] The furnace base 3 supports the furnace body 7 and the table portion 4 . The furnace body 7 and the platform 4 are fixed to each other. Such as figure 2 As shown, the furnace base 3 is connected to the table portion 4 by a rotating shaft 3a. The furnace base 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com