A seed metering mechanism for directional seeding and a secondary suppression seeder

A technology for seeding mechanism and seeder, which is applied to the parts of seeder, sowing seeder, sowing, etc., can solve the problems of inconsistent peanut emergence time, loose soil, inconsistent germ orientation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

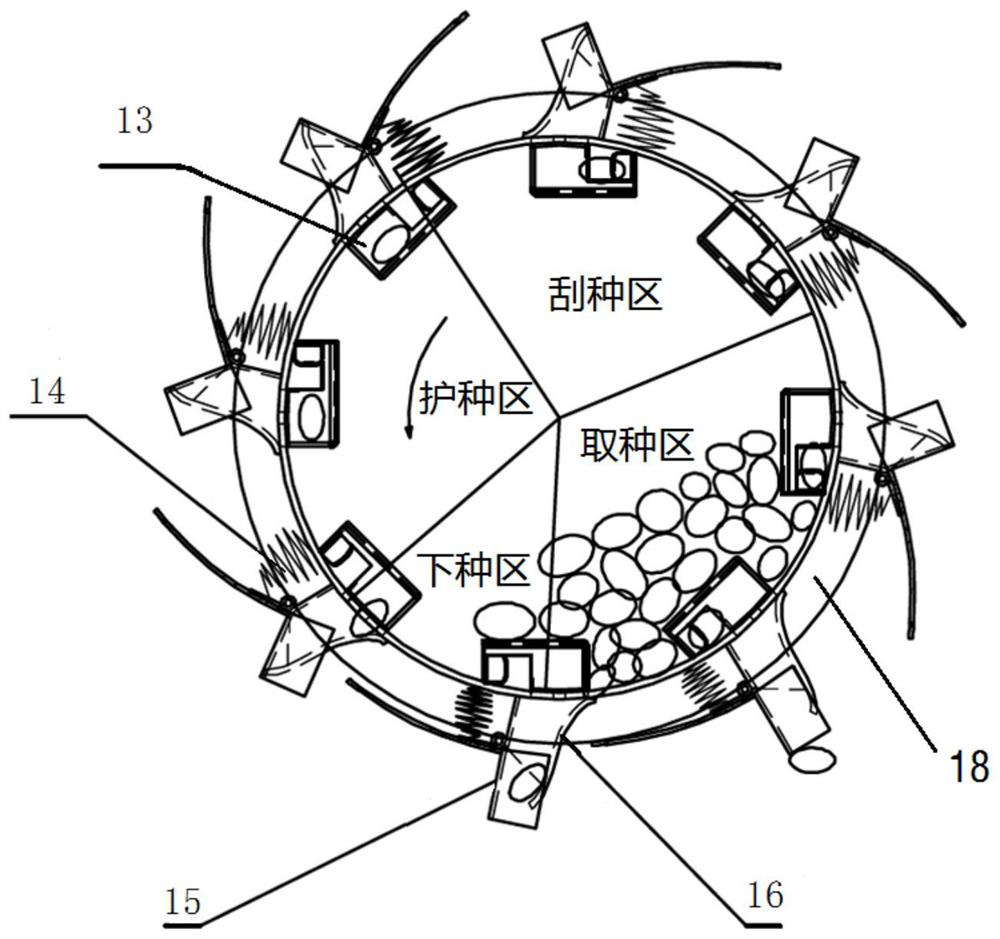

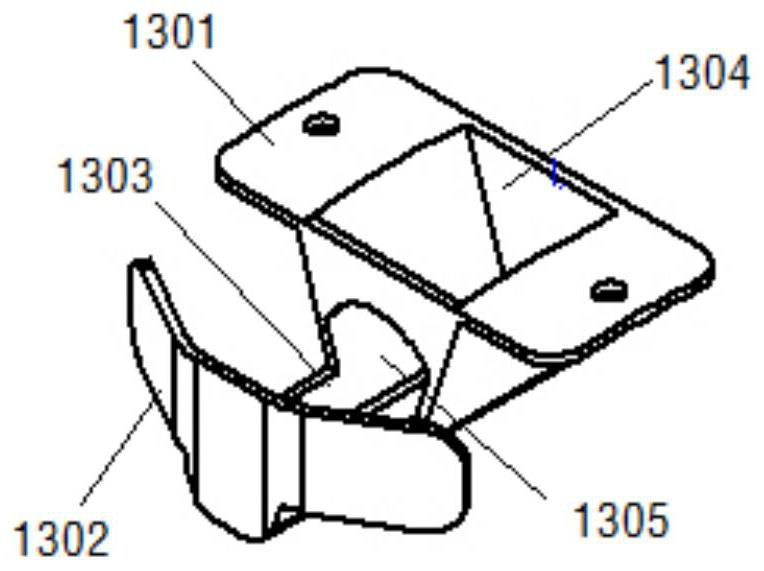

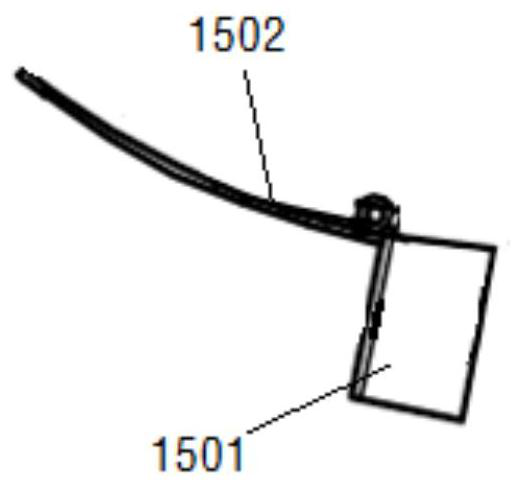

[0033] Such as Figure 1-5 As shown, the present embodiment provides a kind of directional seeding mechanism (the seeding mechanism here can be referred to as a seed meter again), including a sowing circle 18, and the two ends of the sowing circle pass through the end plate (Fig. (not shown) closed, the side wall of the sowing ring is evenly distributed with a plurality of through holes along the circumferential direction; each through hole is respectively fixed with a fixed duckbill 16 with an inner channel, the fixed duckbill One end of 16 protrudes into the through hole, and the other end protrudes away from the through hole.

[0034] It should be pointed out that although the two ends of the sowing circle are closed by end plates, a seed inlet should be provided at one of the end plates, and the seed inlet should be connected with the upper seed box through a pipe, so that the seed box can flow toward the sowing circle. Seeds are provided in the inner cavity, and the spec...

Embodiment 2

[0049] Such as Figure 6-8 As shown, the present embodiment provides a secondary suppression seeder, including a frame 1, and the bottom of the frame 1 is sequentially equipped with a ridging shovel 2, a seeding mechanism 4, a film covering mechanism, and a soil covering mechanism on the film. The lower part of the frame 1 is also equipped with a primary pressing roller 3 and a secondary pressing wheel 10 that can rotate along its own axis respectively; The roller 3 includes a roller body 32, and at least one annular boss 33 is provided on the outer circular side of the roller body 32, and the annular boss 33 can extrude a seed ditch on the upper surface of the field ridge.

[0050] The primary pressing roller 3 can utilize itself and the gravity of the frame 1 to squeeze the field ridge during the movement of the random frame 1, so as to realize the compaction and compaction of the field ridge before sowing; the secondary pressing wheel 10 is installed on the The soil coveri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com