Chemical experiment stable steam flow generator

A chemical experiment and generating device technology, applied in the field of chemistry, can solve the problem that the steam flow generating device is not suitable for active reagents, etc., and achieve the effects of avoiding reagent decomposition or changing chemical properties, reducing volume, and accurately evaporating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

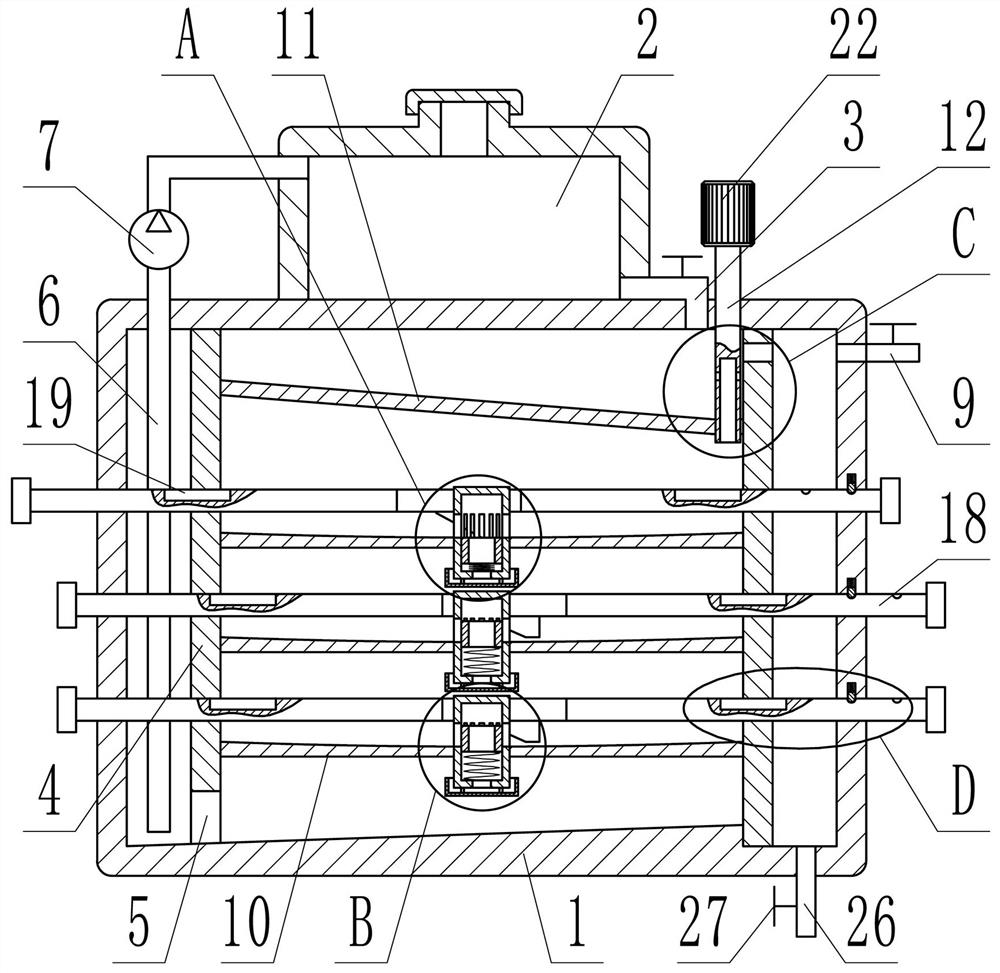

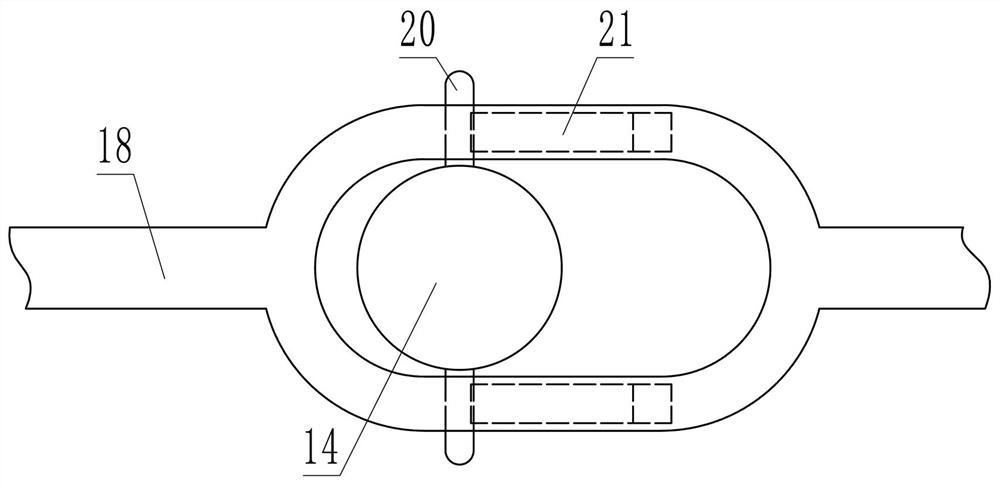

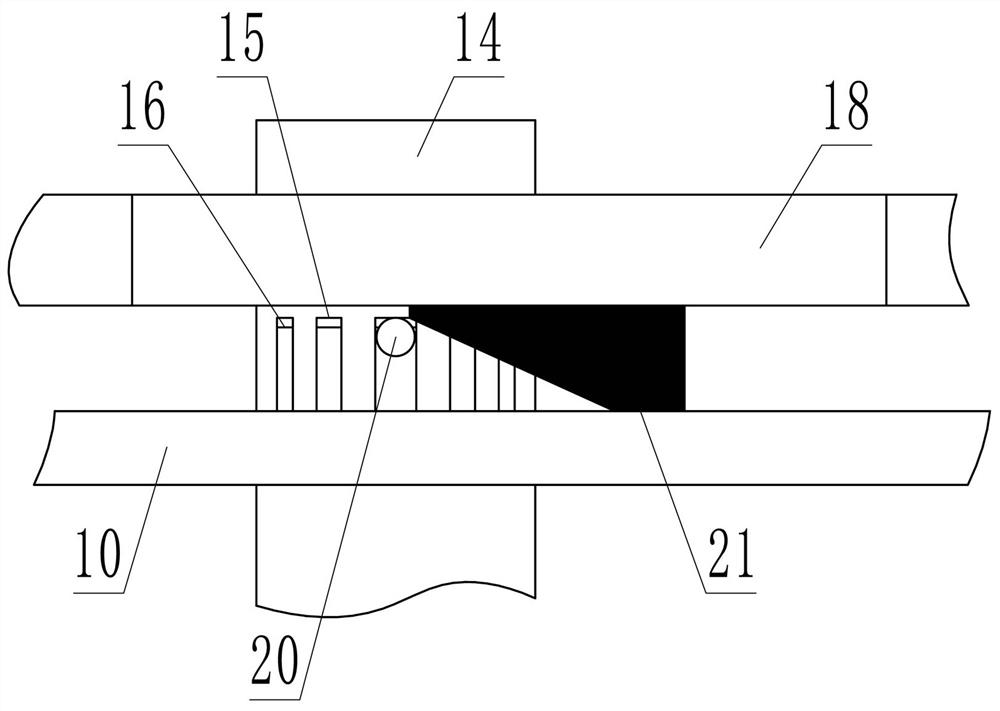

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Depend on Figure 1 to Figure 9 Given, the present invention includes a housing 1, a liquid storage chamber 2 is arranged above the housing 1, and the liquid storage chamber 2 communicates with the top of the housing 1 through a liquid inlet pipe 3, and two vertical chambers are arranged at intervals in the left and right sides of the housing 1. Plate 4, two risers 4 separate the housing 1 into a left chamber, a middle chamber and a right chamber, the bottom of the left riser 4 has a first through hole 5, and the left chamber is provided with an upper end and a liquid storage chamber. The liquid return pipe 6 connected to the chamber 2, the liquid pump 7 is installed on the liquid return pipe 6, the air hole 8 is opened on the top of the vertical plate 4 on the right side, and the air outlet pipe 9 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com