A porous carbon material loaded feco 2 the s 4 Electrochemical oxygen evolution catalyst and preparation method thereof

A porous carbon material, electrochemical technology, applied in the field of electrocatalytic oxygen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

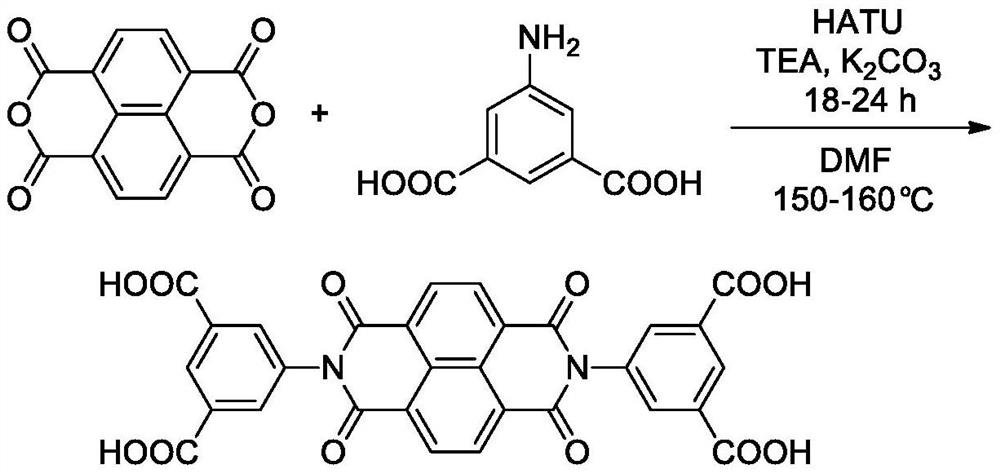

[0026] The organic ligand is a naphthalimide m-dibenzoic acid derivative, and the preparation method comprises the following steps:

[0027] (1) Feed N into the reaction flask 2 Exhaust the air, add N,N-dimethylformamide (DMF) solvent, 1,4,5,8-naphthalene tetracarboxylic anhydride, 5-aminoisophthalic acid, stir well and then add activator triethylamine (TEA ), dehydrating agent 2-(7-azobenzotriazole)-N,N,N',N'-tetramethyluronium hexafluorophosphate (HATU), additive K 2 CO 3, the molar ratio of the five substances is 1:2.4-3:2-3:2-2.4:4-5, the reaction bottle is placed in the oil bath, the oil bath includes a base, and the top of the base is fixedly connected with an installation The top of the installation table is inlaid with a bath pot, the bottom of the bath pot is fixedly connected with a heating pipe, the bottom of the installation table and on the right side of the bath pot is fixedly connected with a vertical rod, and the outer side of the vertical rod is sleeved with...

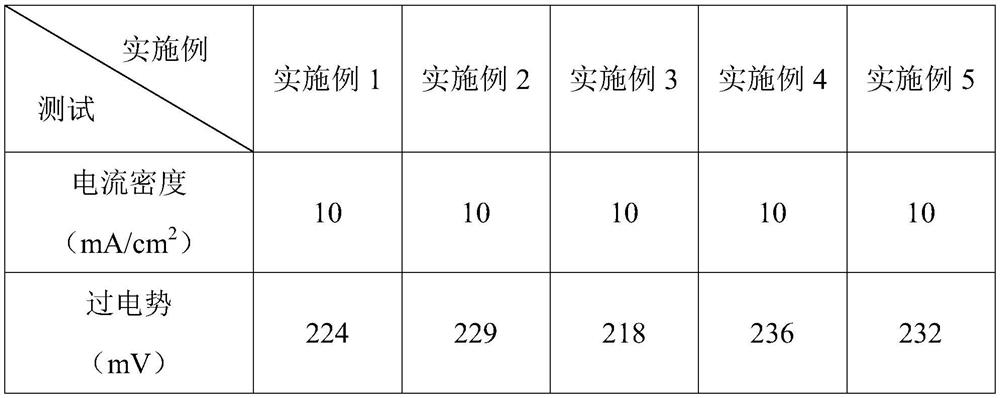

Embodiment 1

[0035] (1) Preparation of organic ligand naphthalimide m-dibenzoic acid derivative 1: feed N into the reaction flask 2 Exhaust air, add N,N-dimethylformamide (DMF) solvent, 1,4,5,8-naphthalene tetracarboxylic anhydride, 5-aminoisophthalic acid, stir well and then add activator triethylamine (TEA ), dehydrating agent 2-(7-azobenzotriazole)-N,N,N',N'-tetramethyluronium hexafluorophosphate (HATU), additive K 2 CO 3 , the molar ratio of the five substances is 1:2.4:2:2:4, the reaction bottle is placed in the oil bath, the oil bath includes a base, the top of the base is fixedly connected with a mounting table, and the top of the mounting table is inlaid with Bathing pot, the bottom of the bathing pot is fixedly connected with a heating pipe, and the bottom of the installation platform is fixedly connected with a vertical rod on the right side of the heating pot. Rod, the left side of the horizontal rod is fixedly connected with a placement frame, the front and back of the slidin...

Embodiment 2

[0039] (1) Preparation of organic ligand naphthalimide m-dibenzoic acid derivative 2: feed N into the reaction flask 2 Exhaust air, add N,N-dimethylformamide (DMF) solvent, 1,4,5,8-naphthalene tetracarboxylic anhydride, 5-aminoisophthalic acid, stir well and then add activator triethylamine (TEA ), dehydrating agent 2-(7-azobenzotriazole)-N,N,N',N'-tetramethyluronium hexafluorophosphate (HATU), additive K 2 CO 3 , the molar ratio of the five substances is 1:2.4:3:2:4, the reaction bottle is placed in the oil bath, the oil bath includes a base, the top of the base is fixedly connected with an installation platform, and the top of the installation platform is inlaid with Bathing pot, the bottom of the bathing pot is fixedly connected with a heating pipe, and the bottom of the installation platform is fixedly connected with a vertical rod on the right side of the heating pot. Rod, the left side of the horizontal rod is fixedly connected with a placement frame, the front and bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com