A ring rolling machine safety protection device

A technology of safety protection device and ring rolling machine, which is applied in engineering safety devices, mechanical equipment, metal rolling, etc., can solve the problems of scalding operators, hidden dangers of personal safety of operators, and easy injury of operators, so as to ensure normal use , Reduce unsafe hidden dangers, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

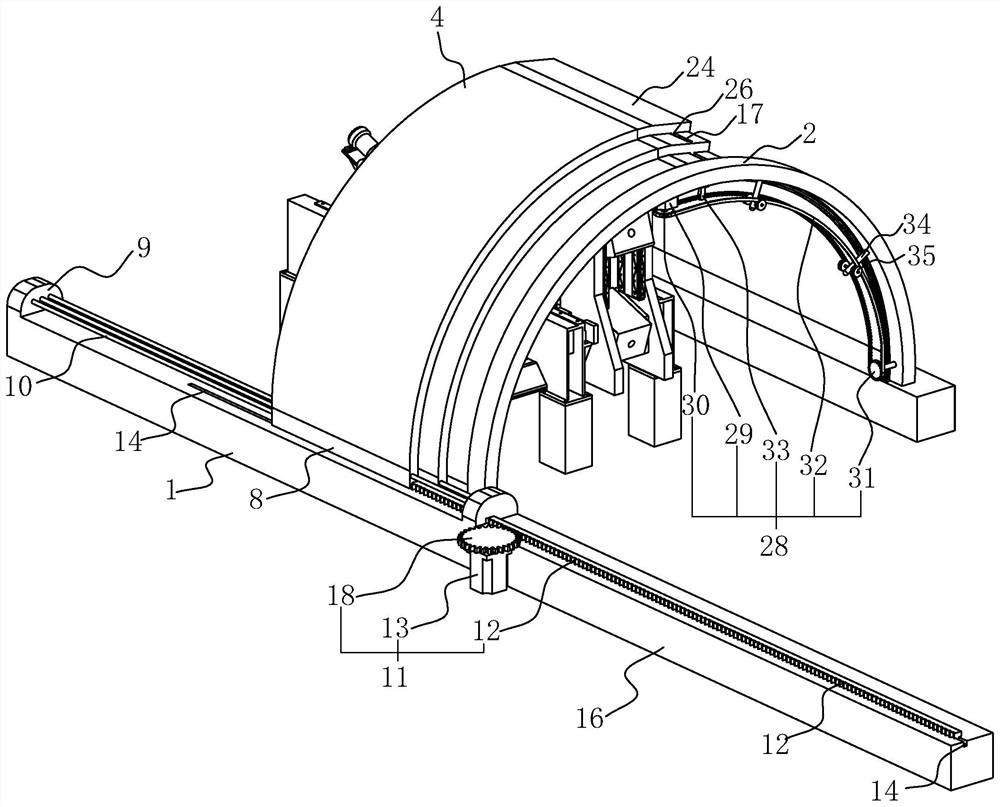

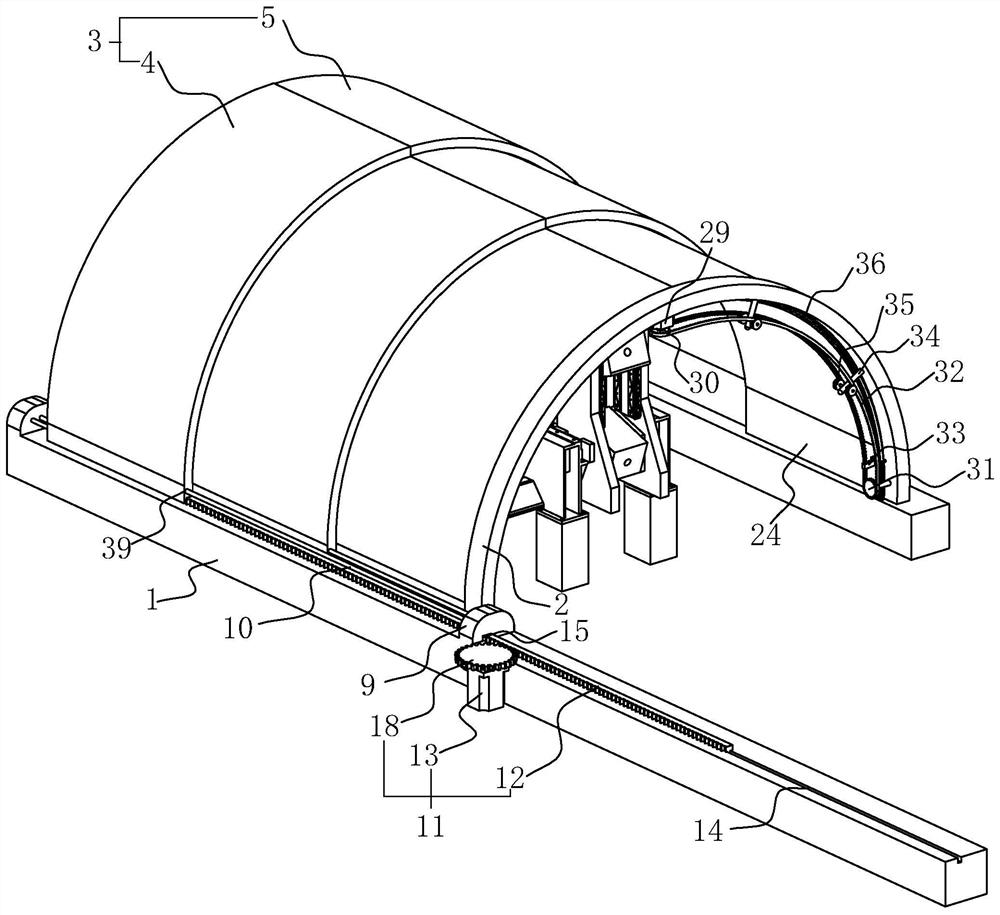

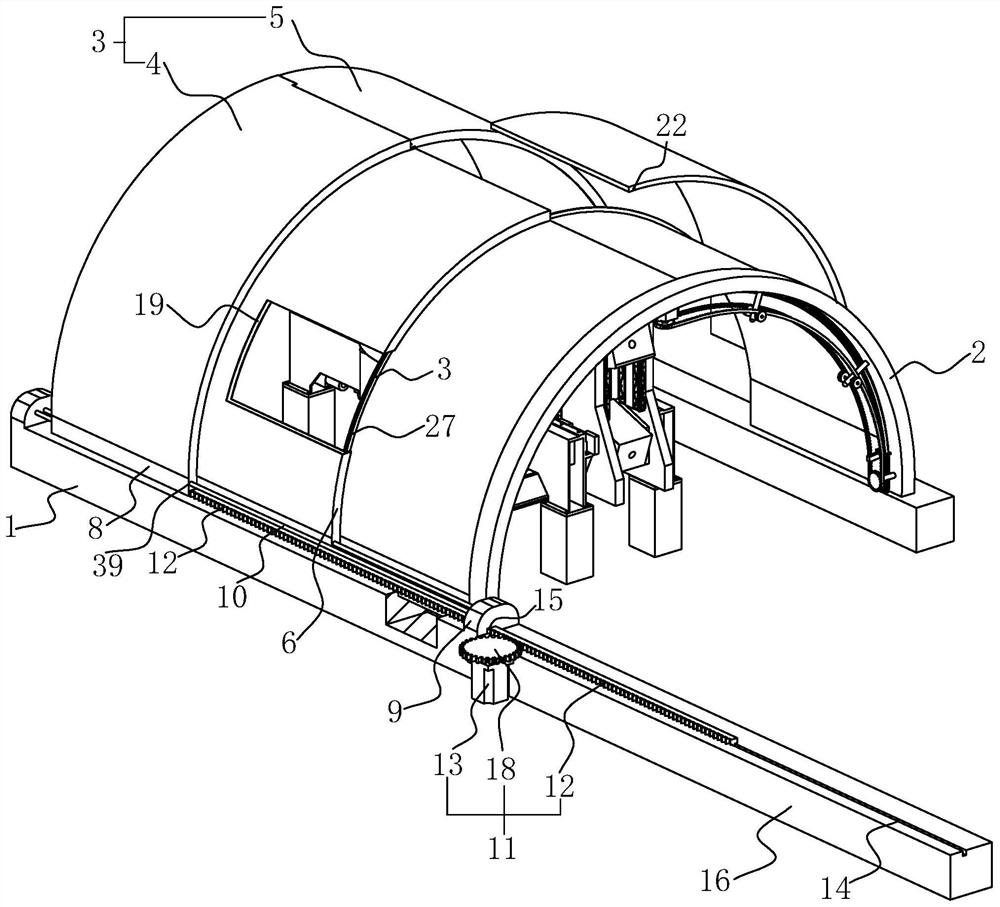

[0042] refer to figure 1 and figure 2 , is a ring rolling machine safety protection device disclosed in the present invention, including a support 1, two supports 1 are provided, and the two supports 1 are respectively located on both sides of the ring rolling machine tool, and the support 1 is along the ring rolling machine tool. The length direction is set; the two supports 1 are provided with a fixed frame 2, the cross section of the fixed frame 2 is set in a semicircle, and the two ends of the fixed frame 2 are fixedly connected with the corresponding support 1 respectively. The side wall of the fixed frame 2 is provided with a protective component 3, which is located above the ring rolling machine. The protective component 3 is used to block the sparks and iron filings generated by the extrusion of the ring forging on the ring rolling machine, thereby ensuring the operation of the ring rolling machine. The personal safety of the operator.

[0043] refer to figure 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com