Suspension-type sliding form and construction method of one-time molding of large-inclination trash rack

A construction method and technology for trash racks, which are applied in water conservancy engineering, infrastructure engineering, construction, etc., can solve the problems of difficulty in construction quality control, difficulty in increasing quality control, and difficulty in safety management, etc., and are conducive to the guarantee of concrete strength. , The construction process is intuitive and controllable, and the effect of reducing unsafe hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Specific embodiments of the invention are provided below in conjunction with the accompanying drawings.

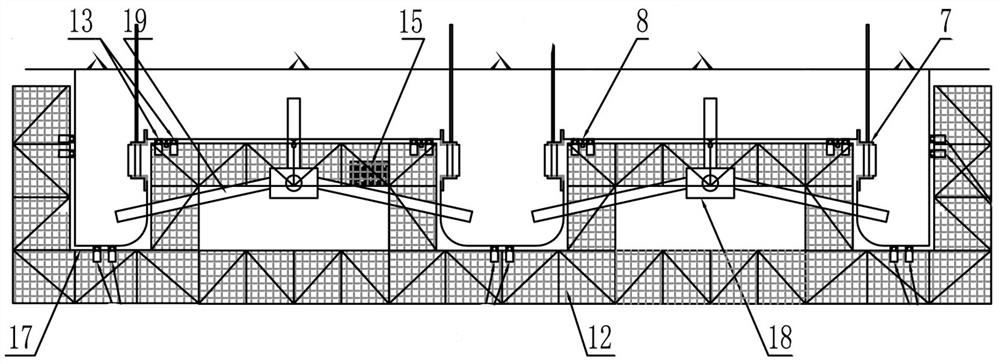

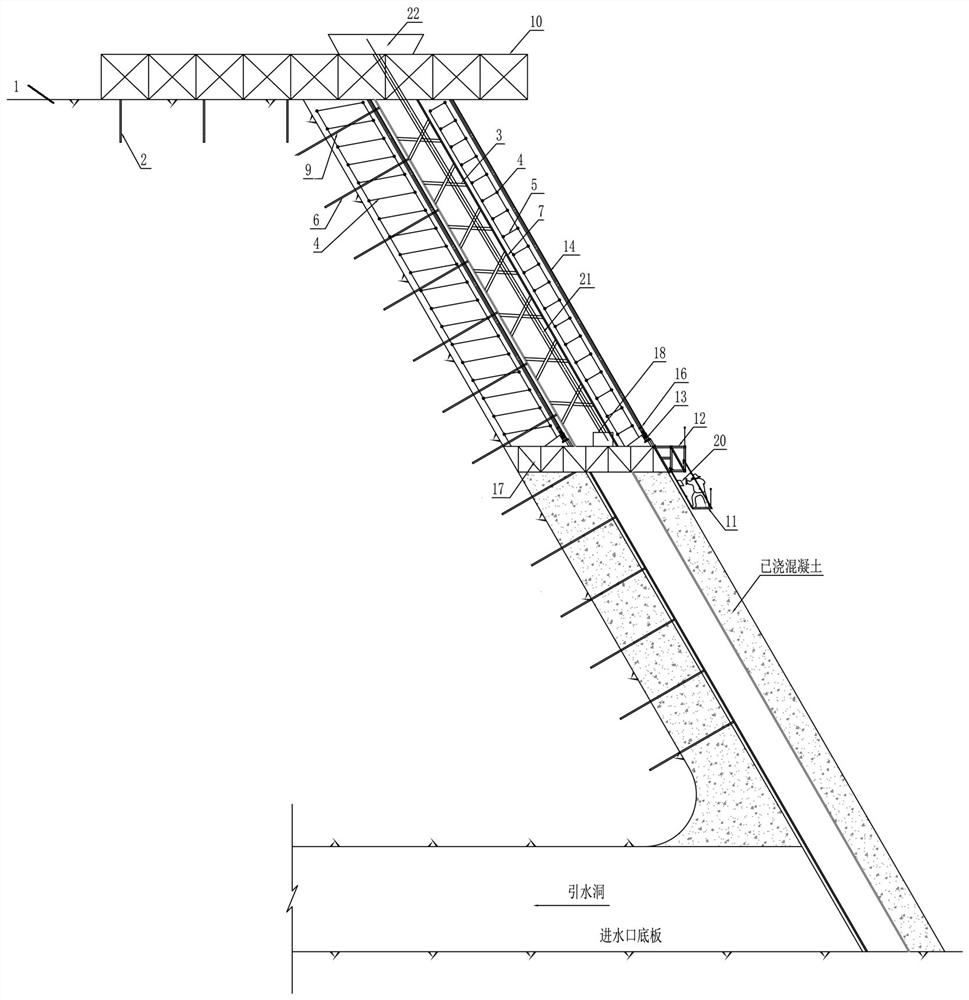

[0047] Such as Figure 1~Figure 2 As shown, a suspension type sliding form of a large-inclination trash rack is formed at one time, including a form system and a suspension system; the form system includes a template 17 in the shape of a trash rack spliced by panels, and ribs and ribs are arranged between the templates 17 The supporting truss; the upper surface of the formwork system is laid with a working platform 12; the working platform 12 is provided with a hydraulic control system; the suspension system includes a suspension support frame 10 of a truss structure, and the suspension support frame 10 passes through the anchor bar 2 and the steel support 3 It is fixed on the rock surface of the trash rack platform 1; multiple groups of suspension rods 14 are connected to the bottom of the suspension support frame 10, and the bottom ends of the suspension rods 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com