Integral hoisting method for components of 5mw land-based wind power generator

A technology for wind turbines and hoisting methods, which is applied in the directions of transportation and packaging, load hanging components, etc., and can solve problems such as high construction costs, large requirements for lifting machinery specifications, and few mechanical resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

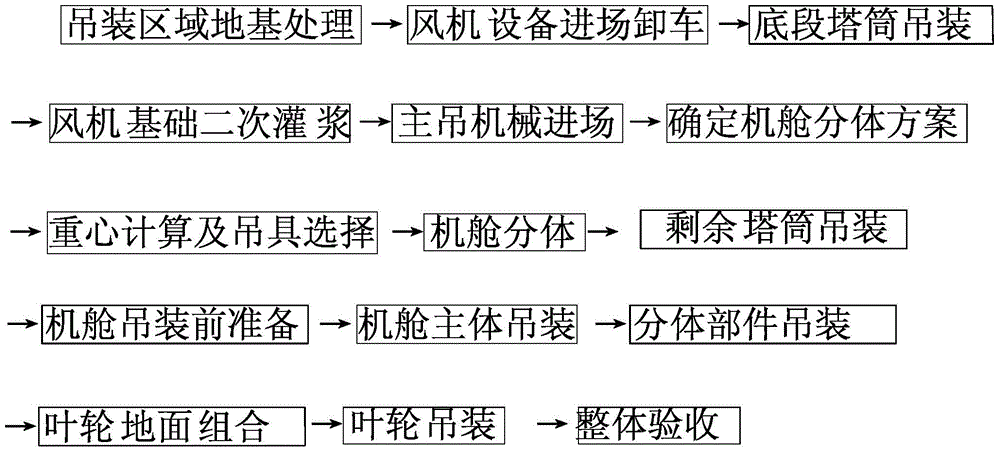

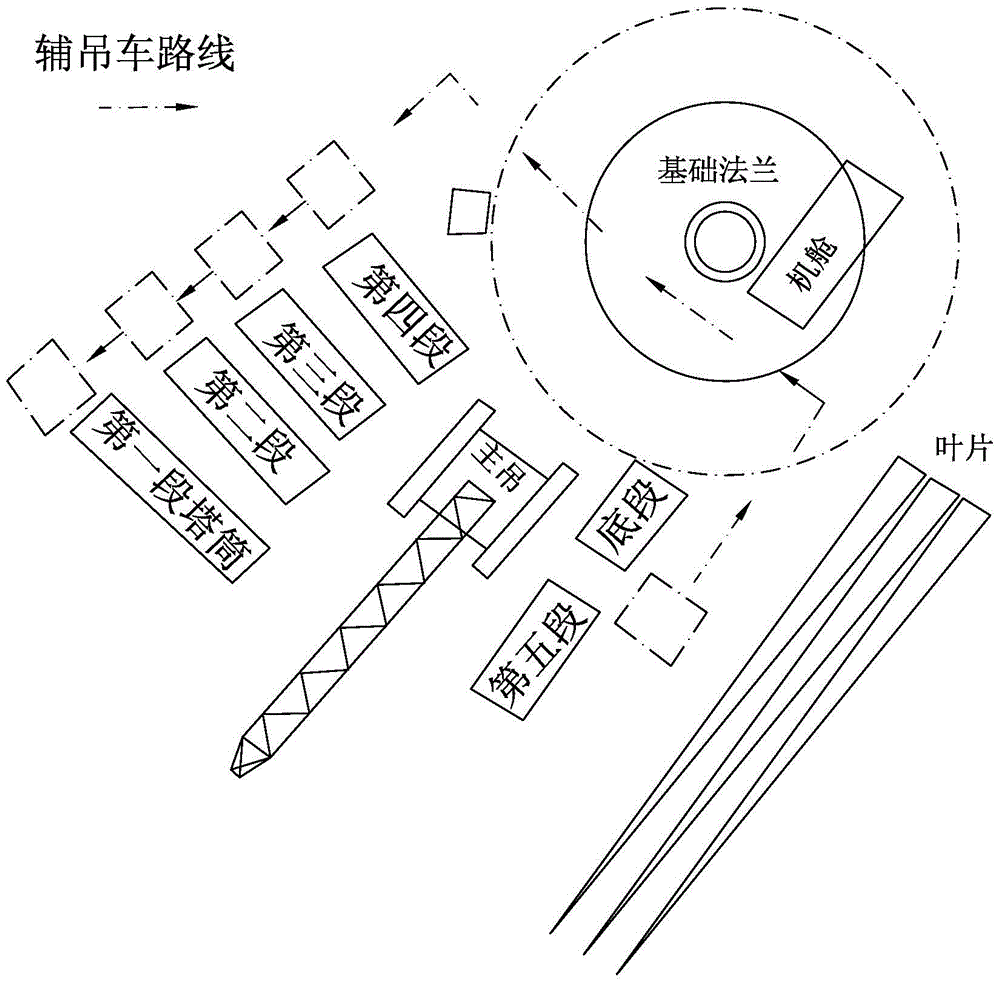

[0093] like Figure 1 to Figure 18 As shown, in view of the existing engineering problems, the main body of protection of this patent is as follows:

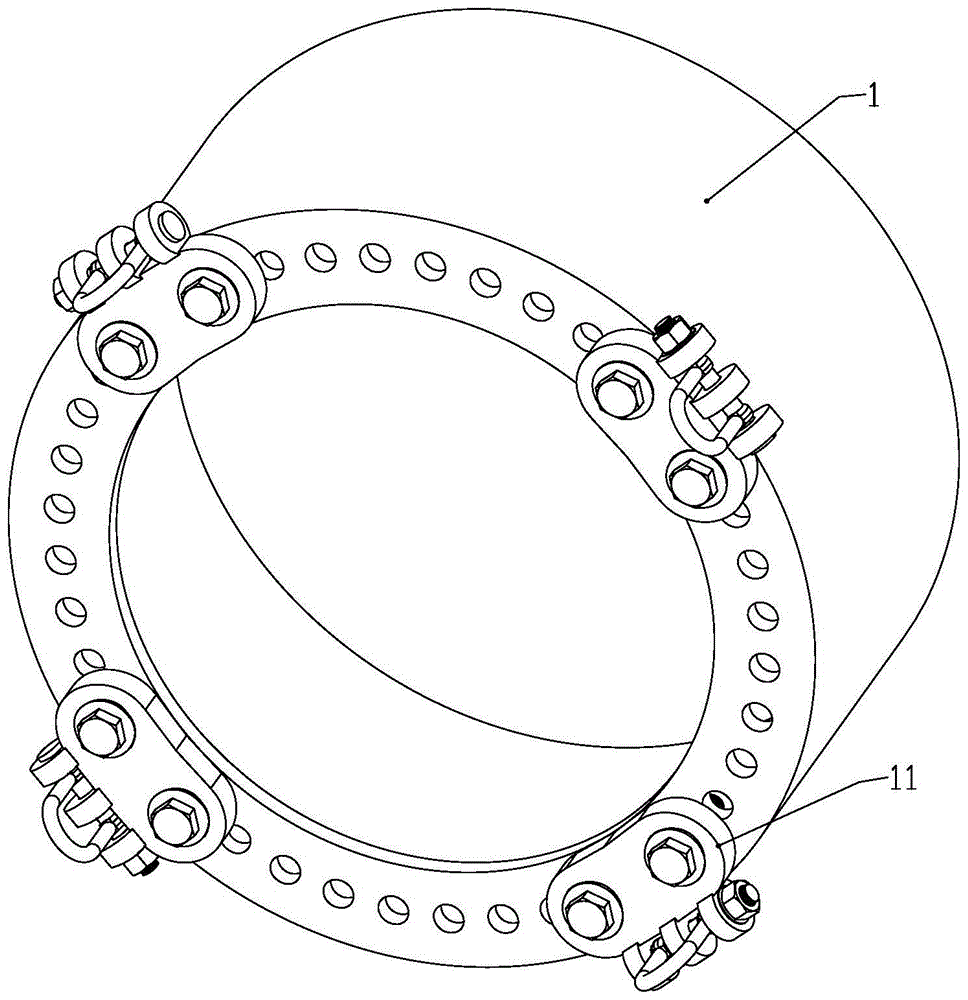

[0094] The development is a 5MW onshore wind turbine group hoisting method. The basic principle is that the nacelle adopts a split hoisting method, and the nacelle is divided into the main body of the nacelle according to the weight, external dimensions of the components of the nacelle and the lifting capacity of the main crane. , generator, maintenance crane and top cover four parts. Before the separation of the engine room, install the positioning devices in the three directions of the generator, and make a record of the whole disassembly process for re-installation. The generator is removed from the engine room and packed in a box, taking measures to prevent moisture and dust. The coupling cover and coupling removed from the nacelle are placed on the platform at the rear of the nacelle and fixed firmly.

[0095] After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com