A Cantilever Erection Method of Zhonglun Steel Truss Girder in Cable-Stayed Bridge

A technology of steel truss girder and cable-stayed bridge is applied in the field of bridge construction, which can solve the problems of increasing the hoisting tonnage, the heavy weight of the full-rotating frame girder crane, and the high cost, so as to speed up the construction speed, reduce the number of hoisting, and reduce the production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0050] An embodiment of the present invention provides a cantilever erection method for a Hualun steel truss girder of a cable-stayed bridge, including:

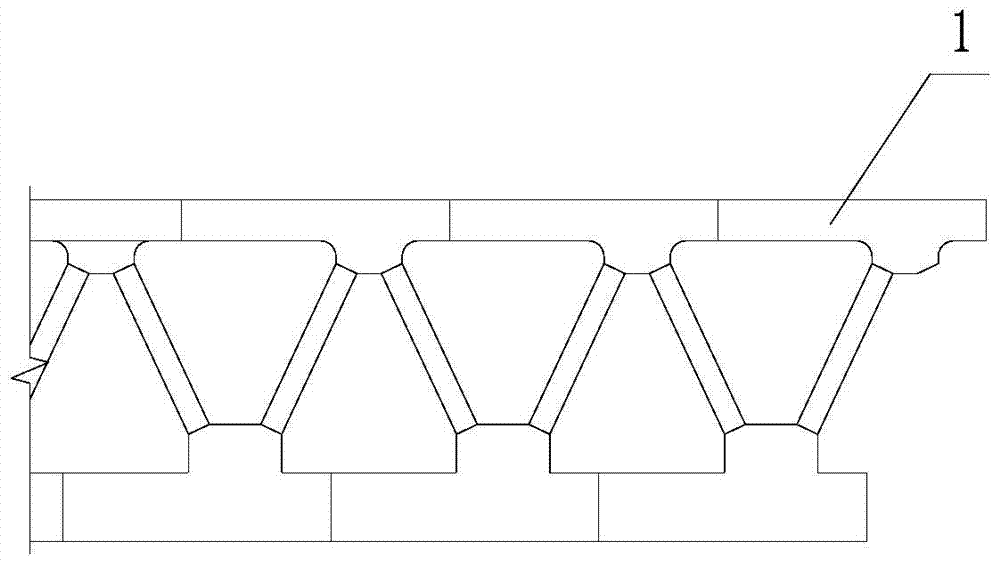

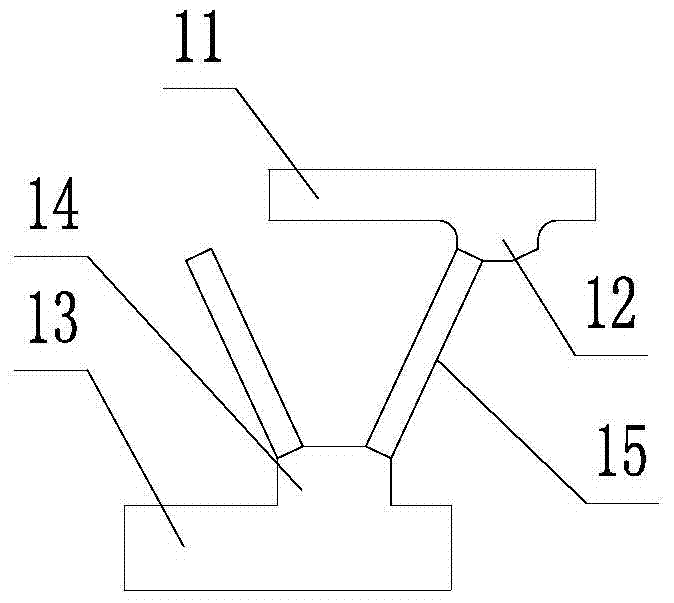

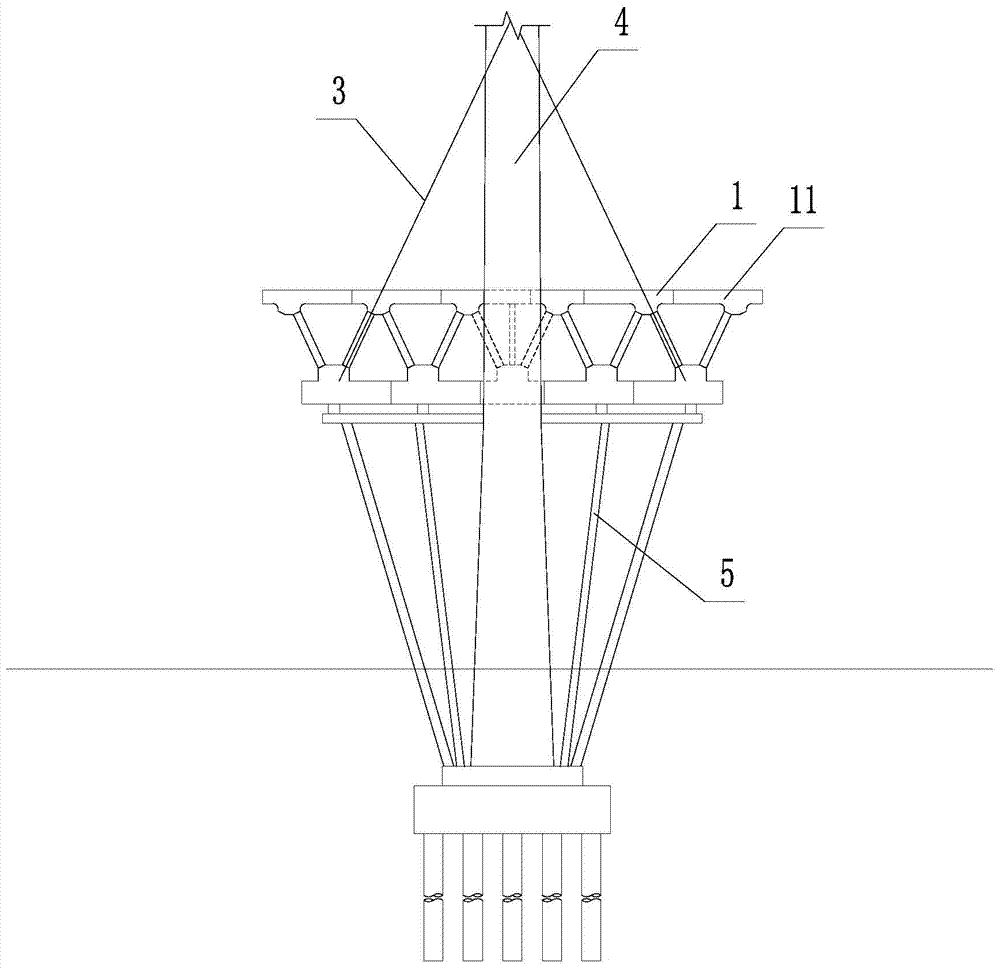

[0051] see image 3 As shown, after the construction of the lower beam of the main tower 4 is completed, the bracket 5 beside the pier is erected, and the steel truss unit 1 located between the top nodes of the pier is installed on the bracket 5 beside the pier; After the truss unit 1 , specifically, the preset number of steel truss units 1 are installed, that is, 3 to 7 steel truss units 1 are installed. A girder erecting crane 2 is respectively installed on the upper bridge deck 11 located at both ends of the pier top section, and the two girder erecting cranes 2 are simultaneously constructed on both sides of the main tower 4, and each girder erecting crane 2 is located on the upper brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com