Modular structure of motor stator and outer rotor of mine hoist

A technology for mine hoists and motors, which is applied to synchronous motors with static armatures and rotating magnets, electric components, electromechanical devices, etc., can solve the problems of difficult assembly, difficult operation, and long cycle, and reduce the difficulty of maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

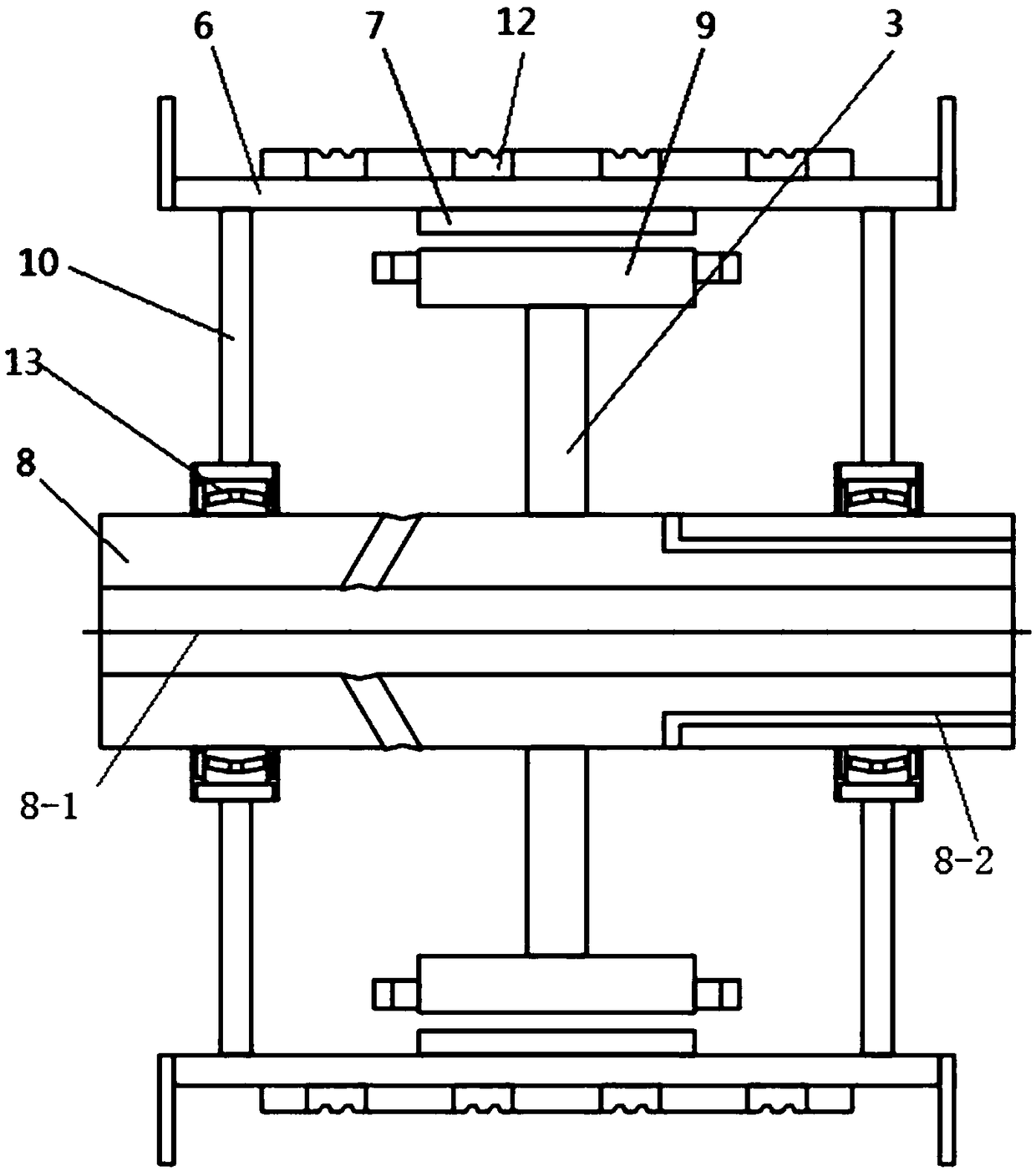

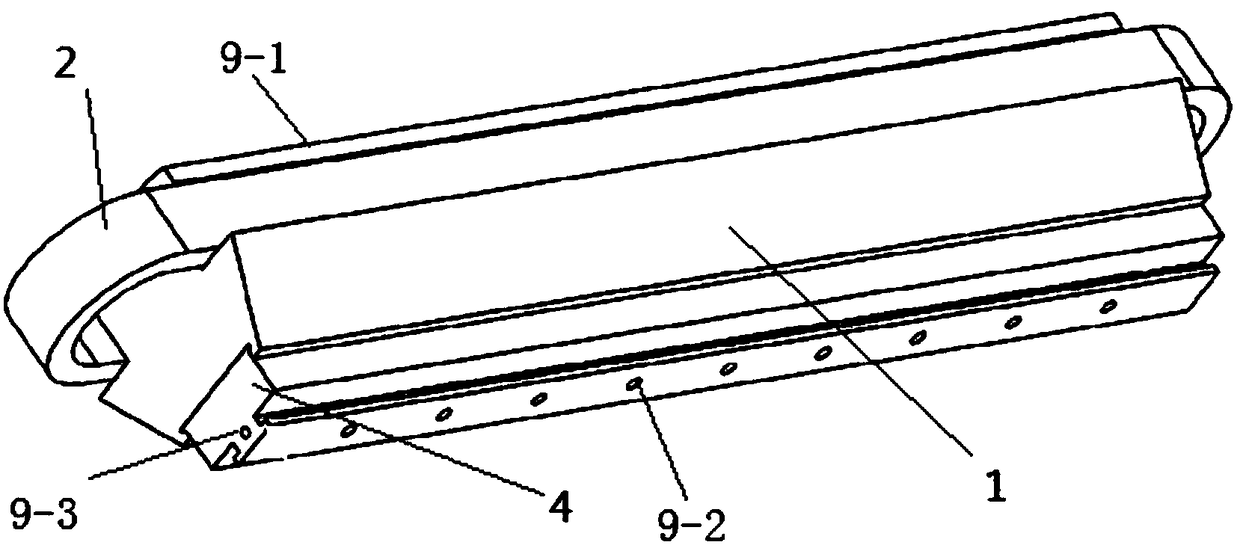

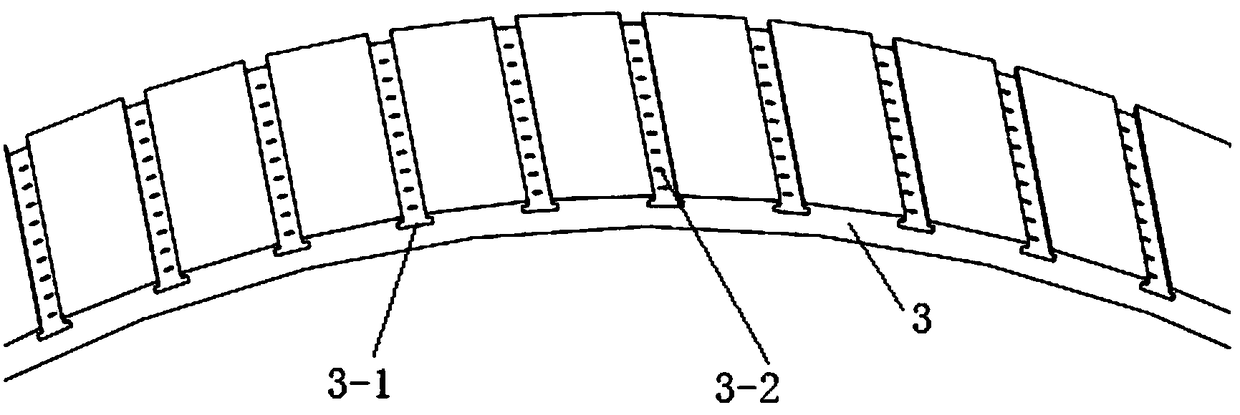

[0034] see figure 1 , figure 2 , a modular structure of a motor stator and an outer rotor of a mine hoist, the motor is a permanent magnet synchronous motor, the stator is set on the static main shaft 8 through a support frame, and the center of the static main shaft 8 is designed with a cable through hole and a cooling water passage. The outer rotor includes a cylindrical rotor case 6 and a rotor pole module 7, a plurality of rotor pole modules 7 are installed on the inner wall of the rotor case 6, the rotor case 6 is set on the stator, and the rotor case 6 passes through the end cover 10 and the bearing 13 is connected with static main shaft 8, and bearing 13 is two rolling bearings, and friction liner 12 is installed on the outer side of rotor casing 6, uses as hoist friction drum simultaneously.

[0035] The stator is composed of a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com