A kind of chemical reaction tower tank body manufacturing method

A manufacturing method and chemical reaction technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary welding equipment, etc., can solve the problem of inability to guarantee the precise connection of the welding position, the inability to guarantee the precision of the two tanks, and the misalignment of the connection position of the two tanks and other problems to achieve the effect of reducing production efficiency, ensuring precision and improving branch chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

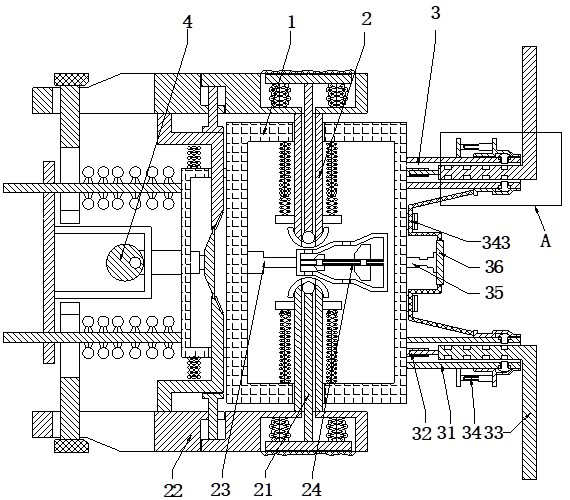

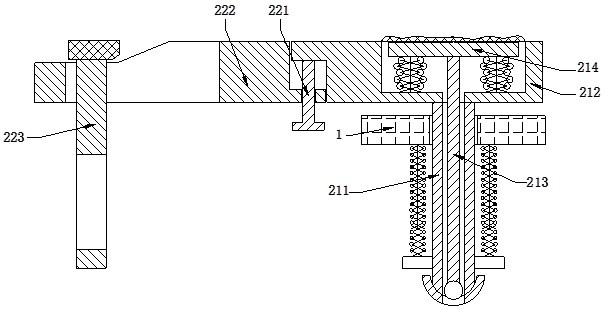

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0033] like Figure 1 to Figure 6 Shown, a kind of chemical reaction tower tank body manufacturing method, this reaction tower tank body manufacturing method adopts the following auxiliary equipment to cooperate to complete, and this auxiliary equipment includes assembly frame 1, is arranged on the locking traction device 2 inside assembly frame 1, is arranged on The positioning device 3 at the rear end of the assembly frame 1 and the drive execution device 4 arranged at the front end of the assembly frame 1,

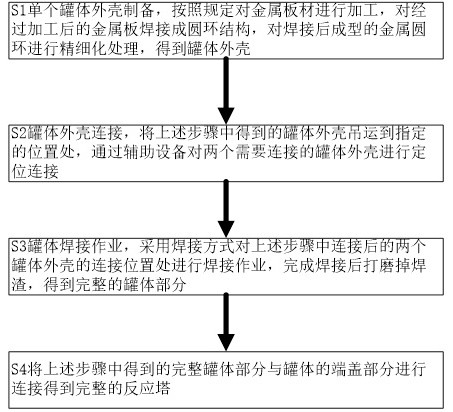

[0034] Adopt above-mentioned auxiliary equipment to comprise the following steps to reaction tower tank body manufacturing:

[0035] S1 Preparation of a single tank shell, processing the metal plate according to the regulations, welding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com