Micropore laser-high temperature chemical synchronous compounding processing device and method

A high-temperature chemical and composite processing technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced processing accuracy, reduced processing efficiency, low processing accuracy and efficiency, and achieves the goal of ensuring precision and device structure. Simplicity, surface quality and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

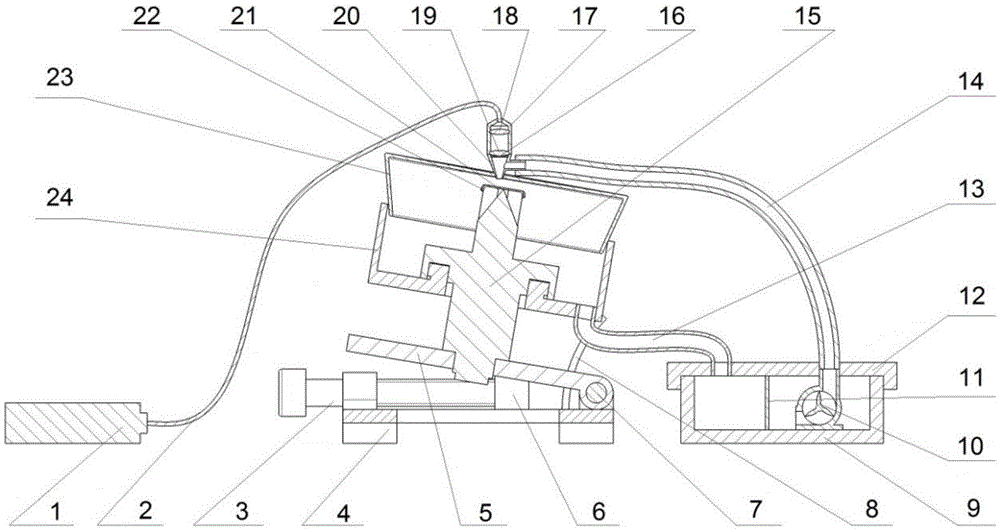

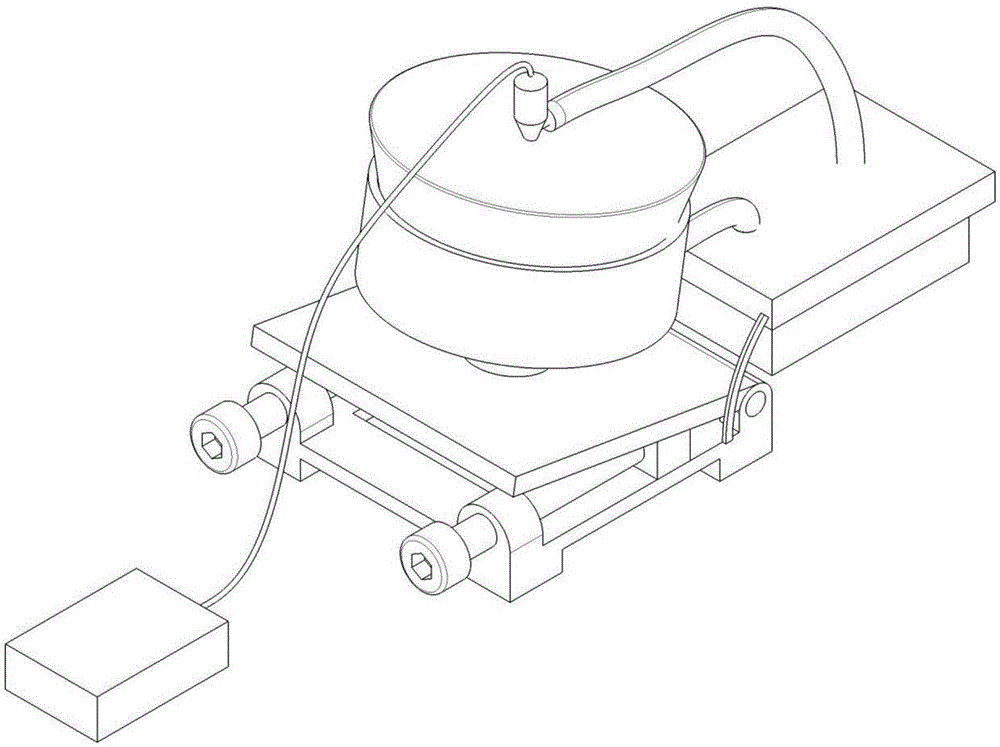

[0052] Such as figure 1 , figure 2 with image 3 As shown, the laser-high temperature chemical synchronous composite processing device is composed of a laser processing unit, a workbench and a chemical processing unit, wherein the laser processing unit is composed of a laser 1, an optical fiber 2 and a laser processing head.

[0053] The laser 1 is a fiber laser, and the output pulsed laser has the characteristics of high peak power, high beam quality, high repetition rate and maintenance-free. One end of the optical fiber 2 is connected to the laser 1, and the other end is connected to the laser processing head, and its function is to transmit the laser beam output by the laser 1 to the laser processing head.

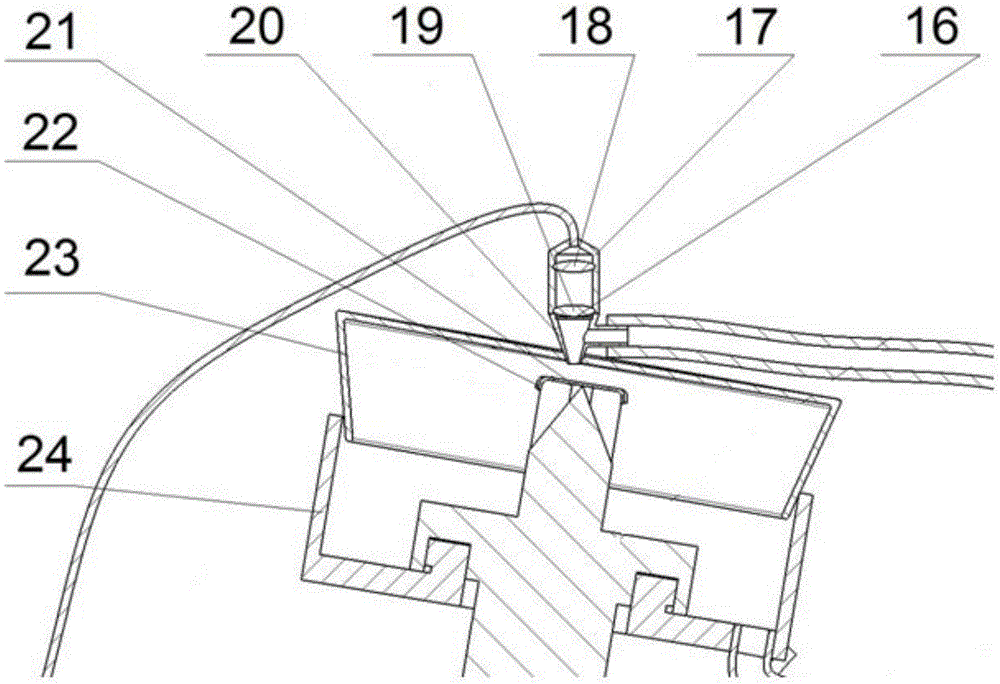

[0054] The laser processing head is composed of a beam expander lens 18 , a focusing lens 19 and a housing 17 . A beam expander lens 18 and a focus lens 19 are installed inside the housing 17 , and the beam expander lens 18 is installed on the upper end of the focu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com