Multi-dimensional adjustable welding gun fixing system

A welding gun fixed and multi-dimensional technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to precisely adjust the position of the welding gun, unreasonable structural design, limited bearing capacity, etc. Reasonable structure and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

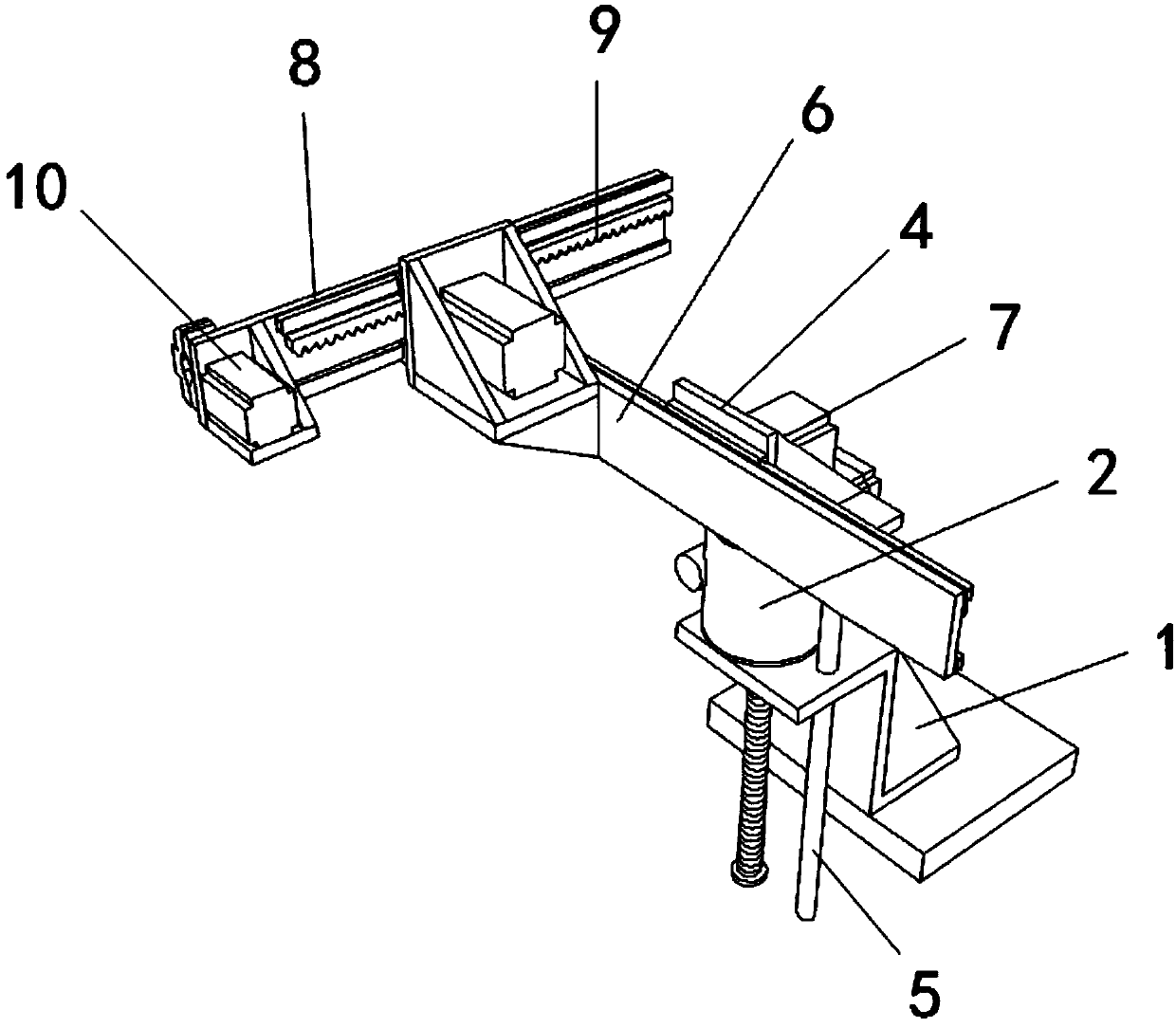

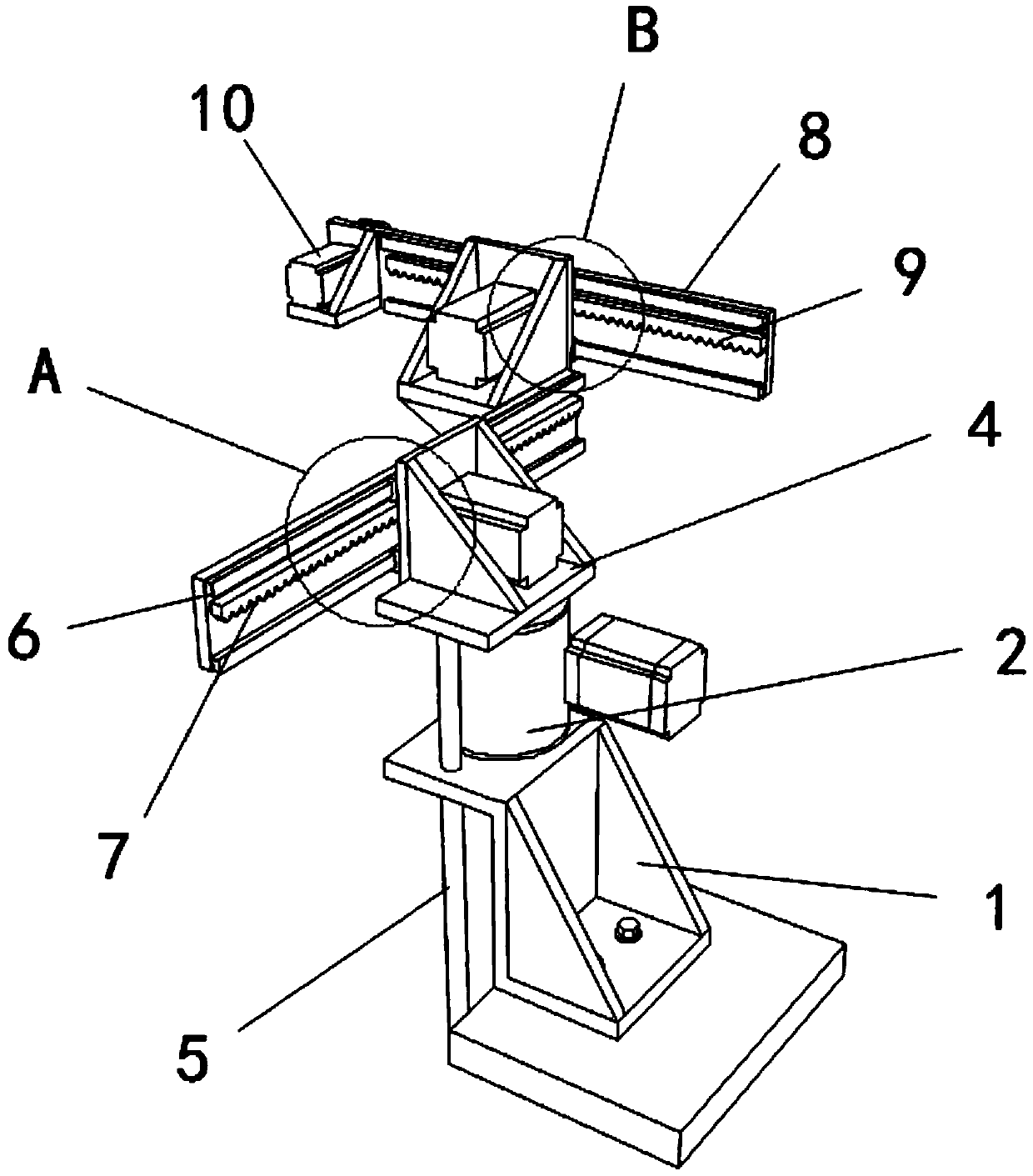

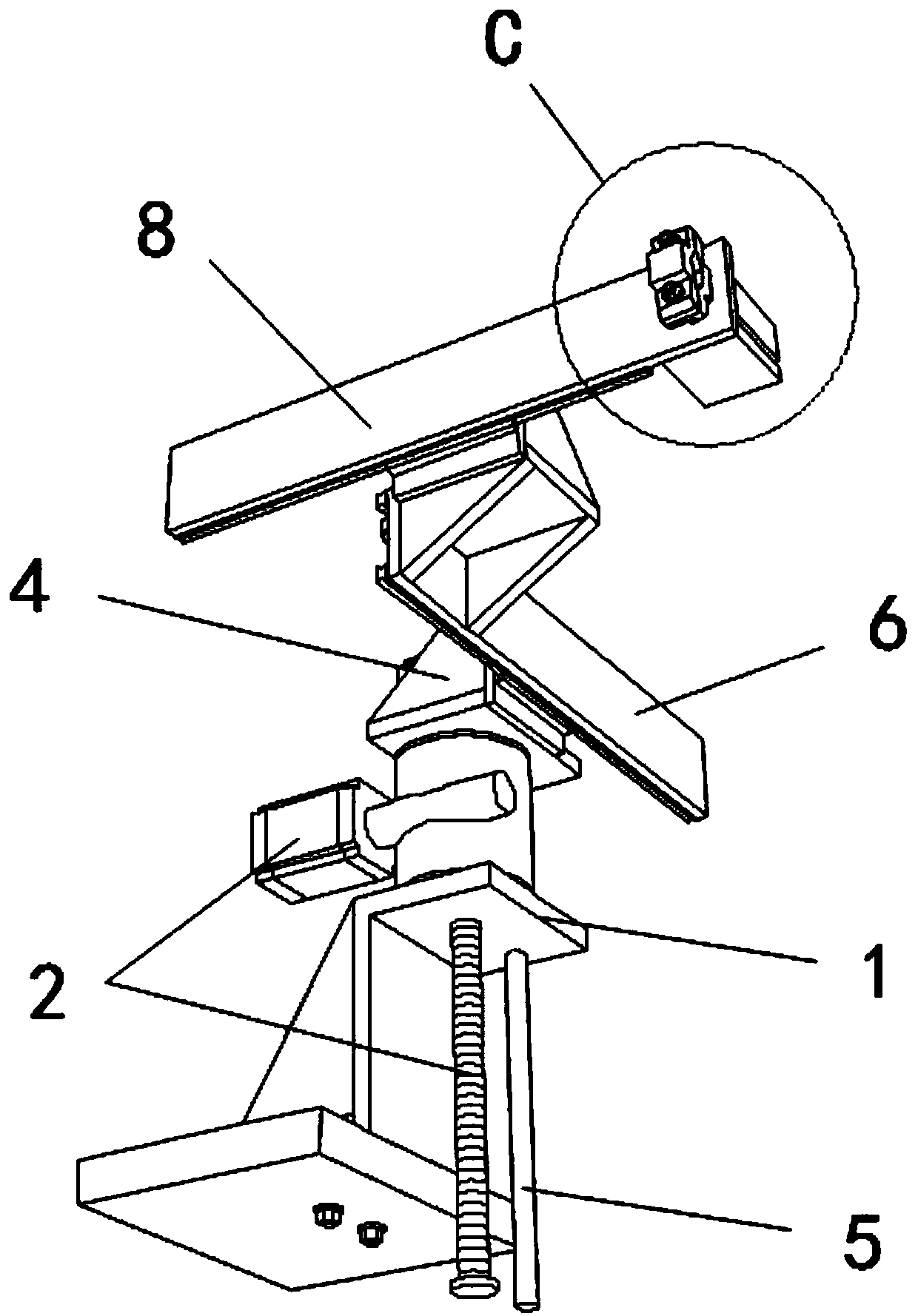

[0033] A multi-dimensional adjustable welding torch fixing system, comprising: a base 1, a screw lifting mechanism 2, a bearing 3, a Y-axis seat 4, a guide post 5, an X-axis seat 6, an X-axis drive assembly 7, a Z-axis seat 8, Z-axis drive assembly 9, rotary chuck 10; the lower end of the base 1 is arranged on the table, and the base 1 is connected with the table by bolts; the Y-axis seat 4 is arranged above the base 1, and the Y-axis seat 4 is passed through The rod lifting mechanism 2 is connected with the base 1; the upper end of the screw lifting mechanism 2 is provided with a Y-axis seat 4, and the screw lifting mechanism 2 is connected with the Y-axis seat 4 through a bearing; the guide column 5 is fixed on the Y-axis The bottom of the seat 4, and the lower end of the guide post 5 is connected with the Y-axis seat 4 in a through way; one side of the Y-axis seat 4 is provided with an X-axis seat 6, and the X-axis seat 6 is connected to the Y-axis through the X-axis drive a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap