A ceramic inkjet printer ink path system

A ceramic inkjet and printer technology, applied in printing and other directions, can solve the problems of incomplete utilization of the ink circuit system, increase the risk of the whole machine, increase the number of pipeline parts, etc., to improve the ability to work continuously and stably for a long time, reduce gas Source processing device and proportional valve, reducing the effect of pressure instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

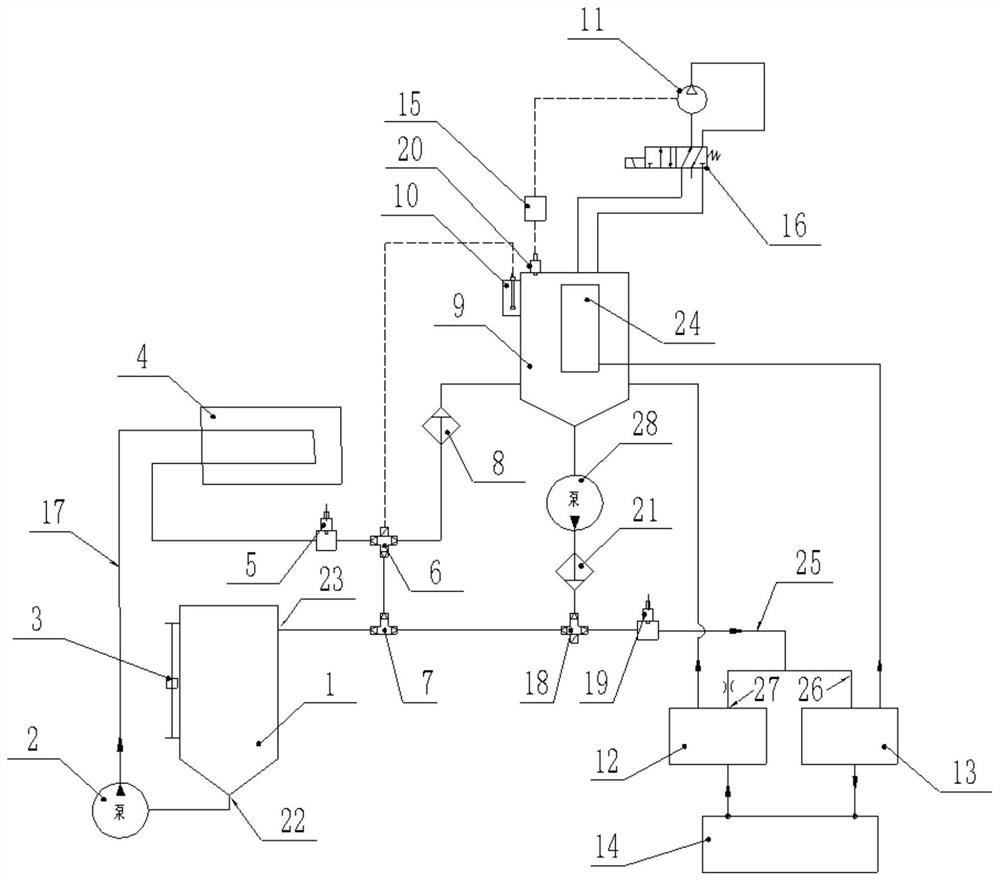

[0029] Such as figure 1As shown, an ink path system of a ceramic inkjet printer includes an ink supply system, a circulation system, an air path system and a control system (not shown in the figure), and the control system is used to control the ink supply system and the circulation system And the air circuit system, the ink supply system includes the ink barrel 1, the ink supply pump 2, the ink supply ink pipe 17, the ink pipes in the ink supply system are collectively referred to as the ink supply ink pipe, and the ink supply pump 2 is used for The liquid in the ink barrel 1 is delivered to the ink supply tube 17, the ink supply tube 17 includes an outlet 22 and a return port 23, and the outlet 22 and the return port 23 are both communicated with the ink barrel 1, The liquid flowing out from the outlet 22 can flow back into the ink barrel 1 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com