Compact rack structure of automobile steering column

A steering column, compact technology, applied to the steering column, steering mechanism, steering control installed on the vehicle, etc., can solve the problems of ignoring the rack structure, meet the space requirements, ensure the collapse energy absorption function, The effect of satisfying the safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

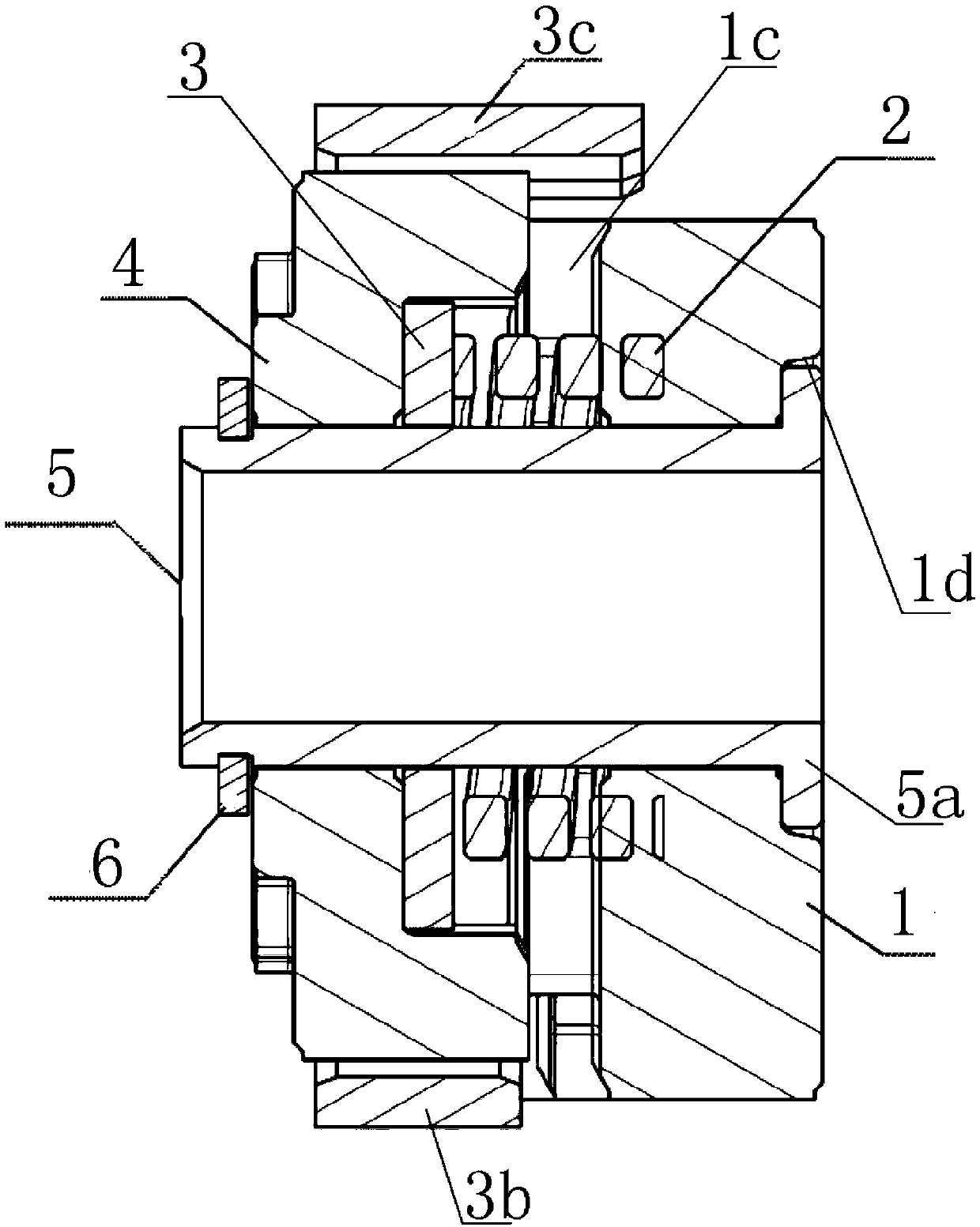

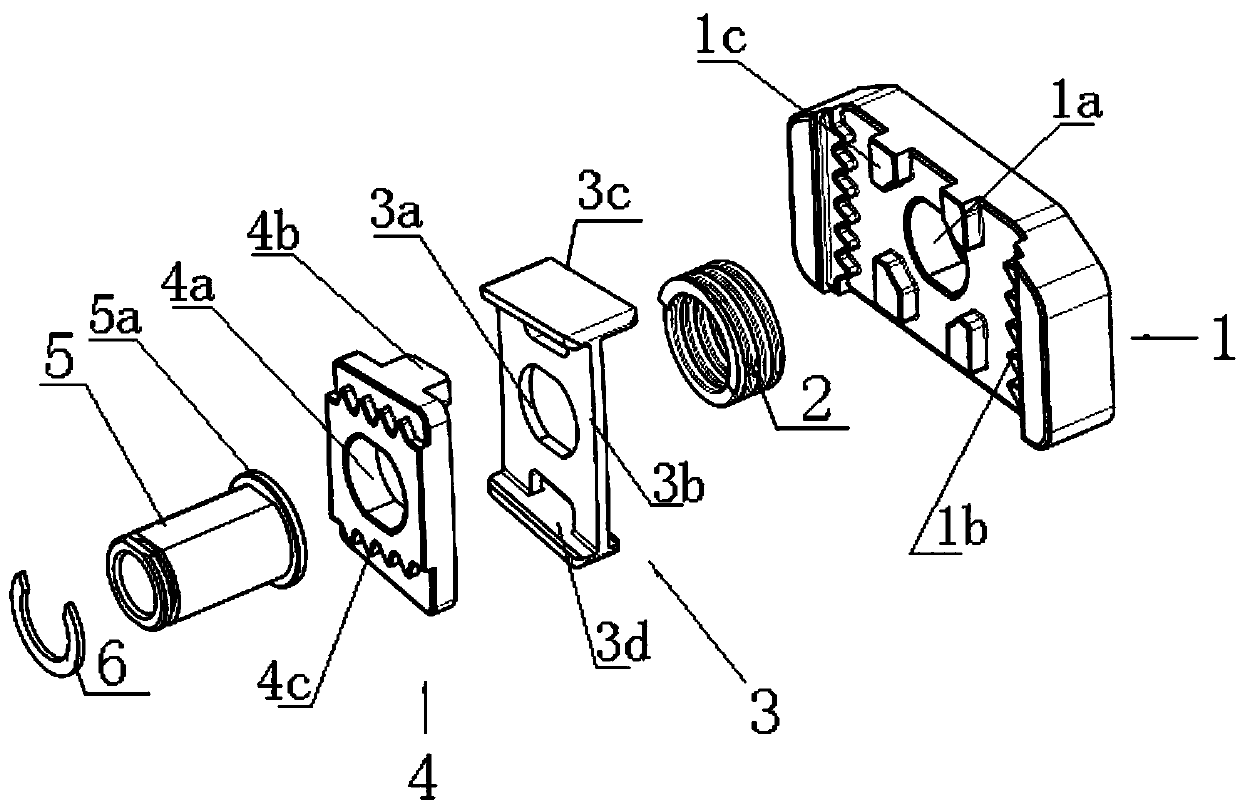

[0025] Such as figure 1 and figure 2 As shown, a compact automobile steering column rack structure includes a radial rack 1, which cooperates with the axially fixed rack of the upper column tube and the spring rack of the U-shaped bracket, and the radial rack The rack is specifically a block rack with a positioning through hole 1a in the center. One side of the radial rack is a plane, and the left and right ends of the other side are respectively provided with vertical longitudinal teeth 1b. Two positioning protrusions 1c arranged in parallel are provided at the upper and lower edges of the upper and lower racks of the positioning through hole on one side of the rack provided with longitudinal teeth;

[0026] A concave step 1d is provided at the center of one side of the plane of the radial rack 1;

[0027] An axial spring 2 is arranged in the rectangular area surrounded by the positioning protrusion 1c, the inner diameter of the axial spring is larger than the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com