Connecting bridge prefabricated reinforced concrete side anti-collision guardrail

A reinforced concrete and prefabricated technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of difficult control of the size of the gap, influence of the construction party, and difficult installation, so as to reduce the risk of overall overturning, avoid stress concentration, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

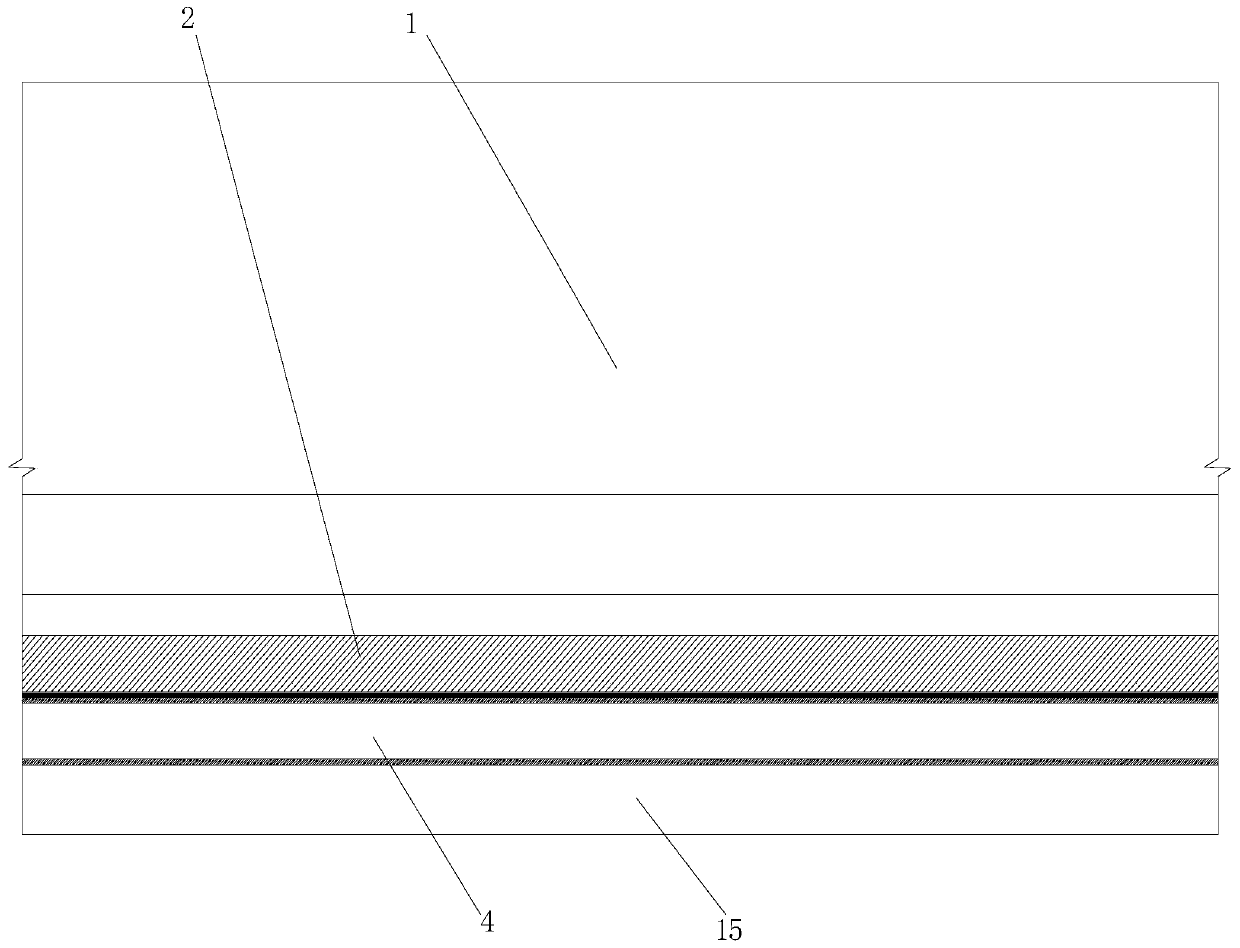

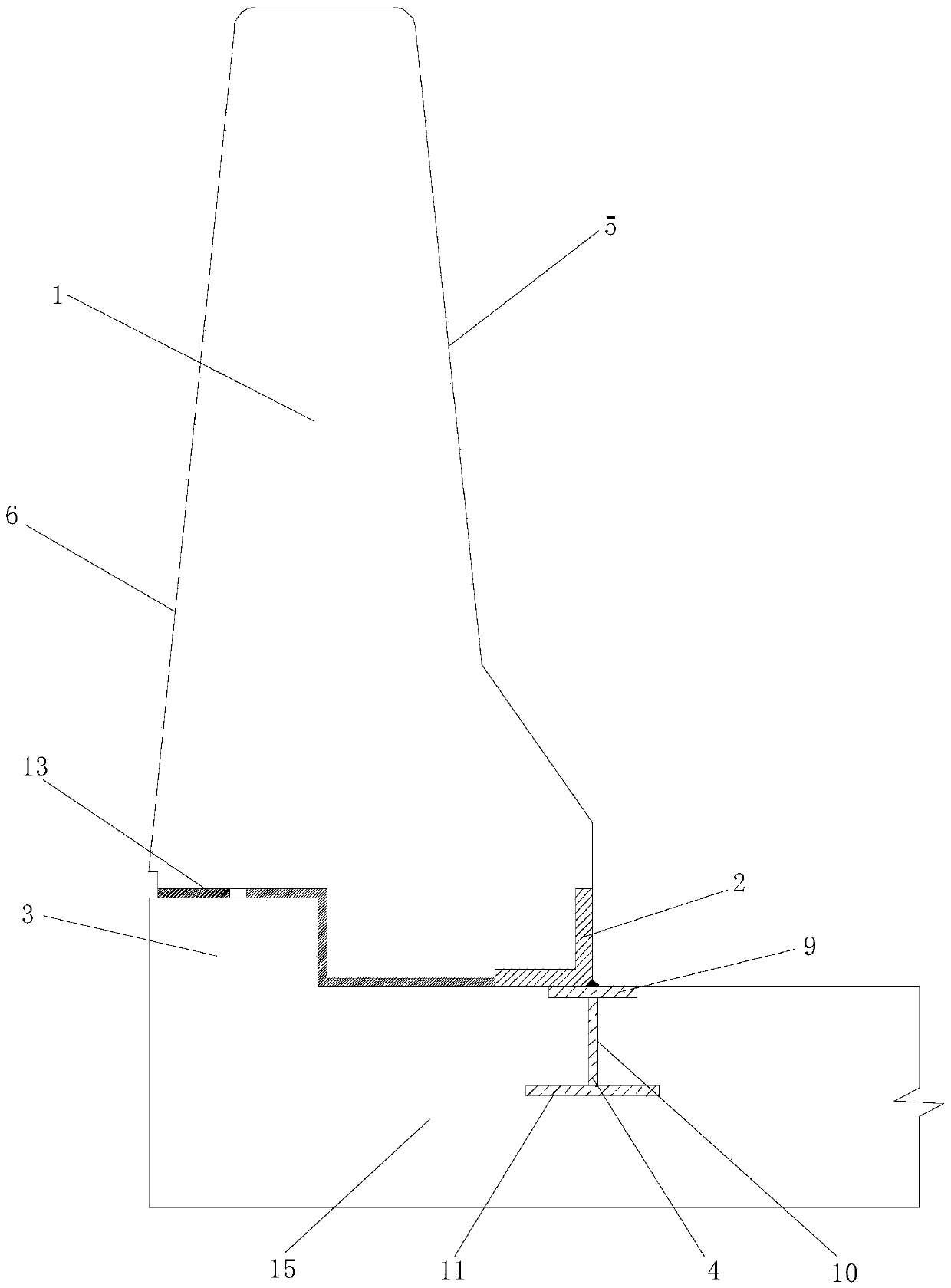

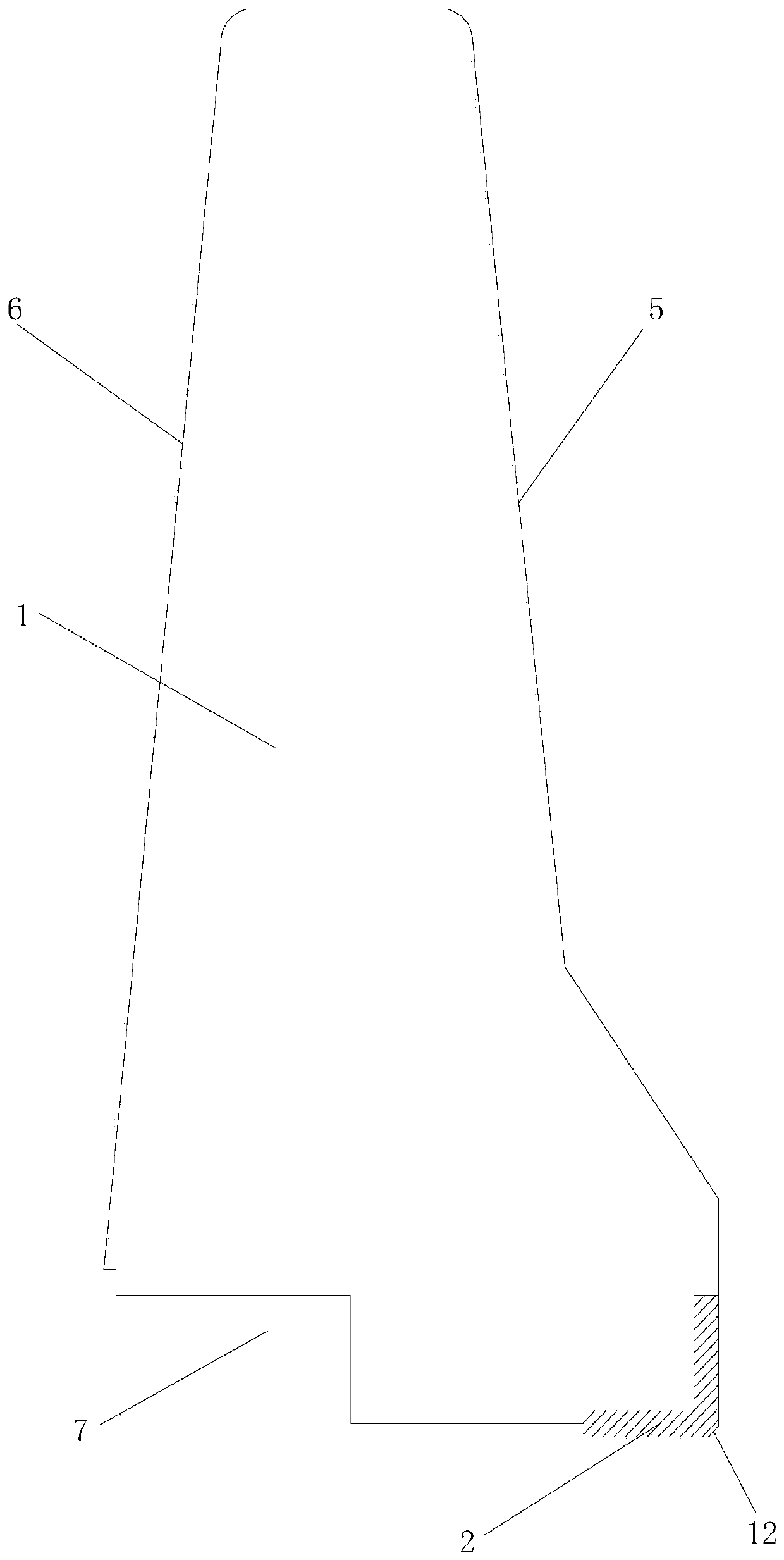

[0043] Such as Figure 1 to Figure 4 and Figure 7The assembled reinforced concrete side anti-collision guardrail for connecting bridges shown includes guardrails, angle steel, blocks fixed on the deck of the bridge and pre-embedded parts embedded in the bridge. The lower end of the guardrail is provided with an embedding groove, and the embedding groove is clamped to the block; the bottom surface between the embedding groove and the colliding surface of the guardrail and the The lower ends are provided with connecting steel bars, which are welded to the two inner sides of the angle steel; the embedded parts include welding plates, connecting plates and reinforcing plates, and the upper and lower ends of the connecting plates are respectively connected with the welding plates and the reinforcing plates, The welding plate is welded to the lower outer surface of the angle steel. Specifically, the thickness a of the welding plate is 10 mm to 15 mm, the thickness b of the reinfo...

Embodiment 2

[0053] On the basis of Embodiment 1, the assembled reinforced concrete side crash guardrail of this connecting bridge increases the following technical features: as Figure 9 As shown, the assembled reinforced concrete side crash barrier of the connecting bridge also includes a rib plate, the first right-angle side of the rib plate is connected to the side of the connecting plate, and the second right-angle side of the rib plate is connected to the reinforcement plate connect. The addition of ribs can further increase the strength of the embedded parts, so as to further improve the stability and reduce the risk of overturning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com