Ultra-high-speed wheelrail vehicle set battery replacement railway system

A train set and ultra-high-speed technology, applied in the direction of railway transportation, railway vehicles, railway transport, etc., can solve the problems that the implementation concept of ultra-high-speed wheel-rail train set cannot be put into practice, and the problem of battery life cannot be effectively solved, so as to achieve the overall layout Simple and compact structure, easy to popularize and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

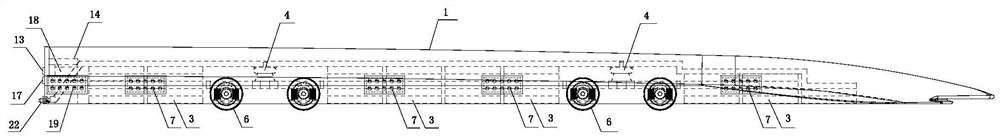

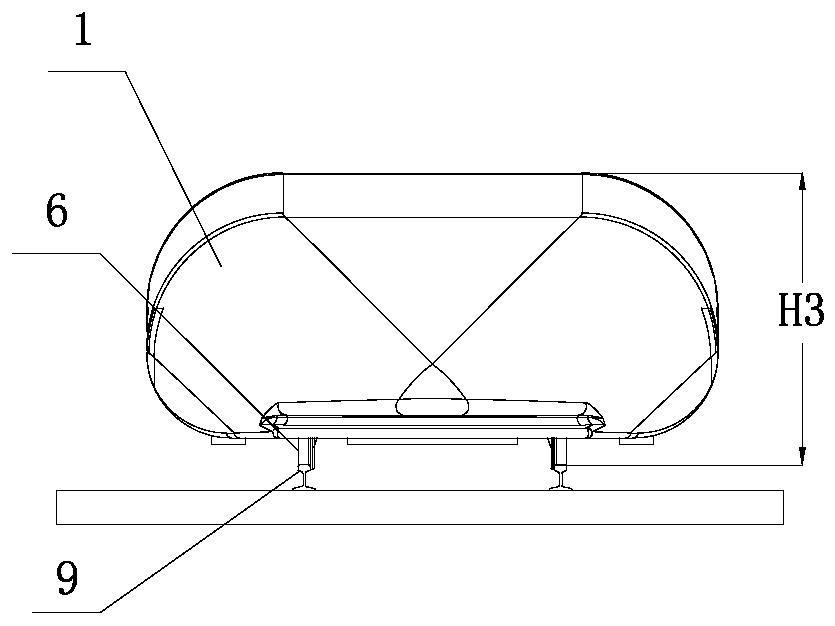

[0077] Embodiment 1: In combination with the figure, a kind of ultra-high-speed wheel-rail train set power exchange railway system related to the present invention is composed of two parts: an ultra-high-speed wheel-rail train set and a power exchange station. The traction locomotive head 1 is a pure electric traction locomotive head directly driven by the power battery pack 3, which is provided with a power battery pack charging interface 7 connected to the internal power battery pack 3; and the power station is arranged on an ultra-high-speed wheel rail The running track 9 of the train set is specially used for quick replacement and charging of the traction locomotive 1 . The following describes the two as follows:

[0078] combine first Figure 1~Figure 9 As shown in Figure 14, the ultra-high-speed wheel-rail train set is described, and its whole is composed of a car set composed of four cars 2 and a traction locomotive 1 connected to the head and tail of the car set that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com