Fabricated composite ceramic tile

A prefabricated, ceramic tile technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of increasing the load-bearing of buildings, cumbersome paving process, non-reusable, etc., to reduce weight, reduce labor burden, and light structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

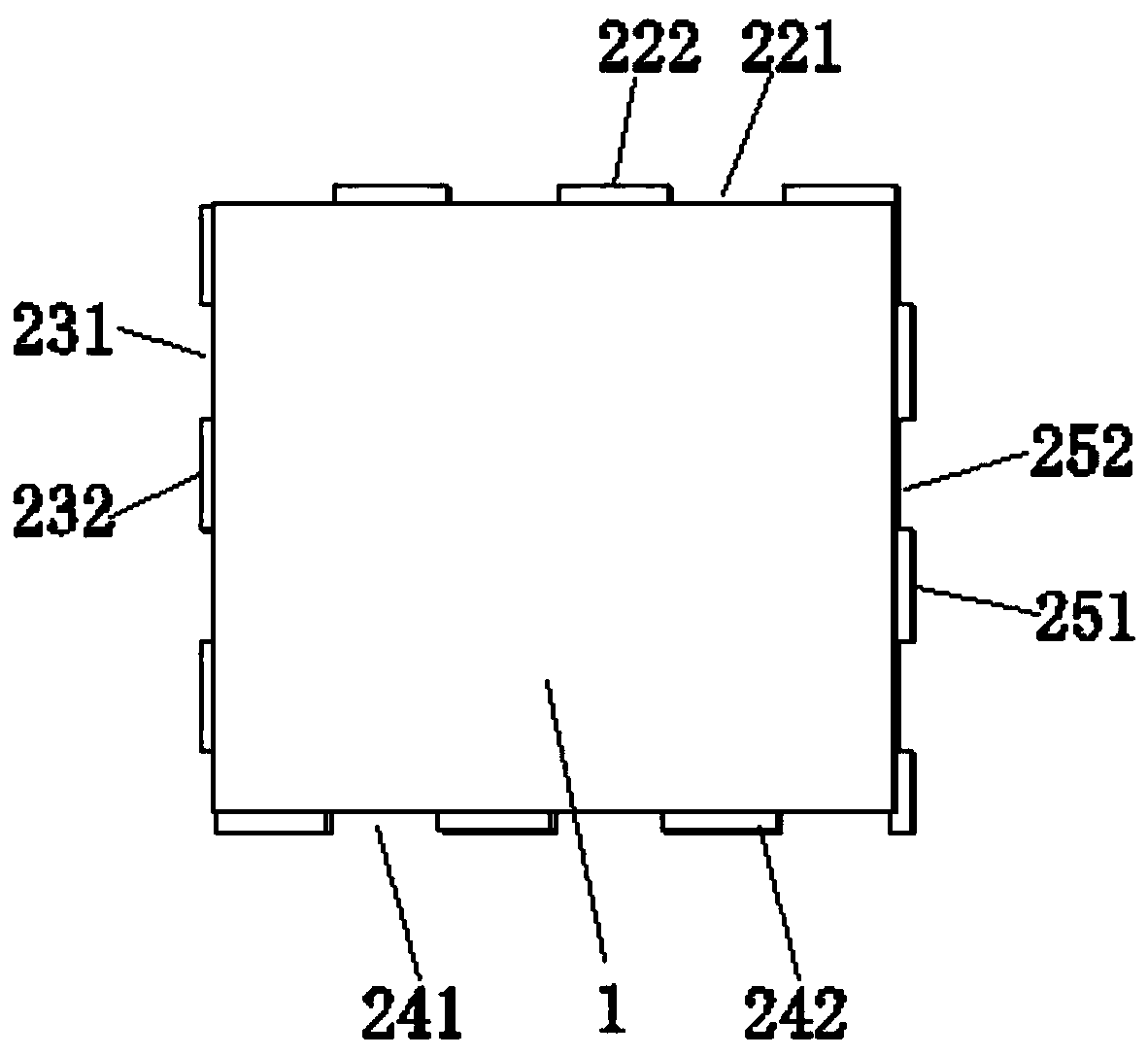

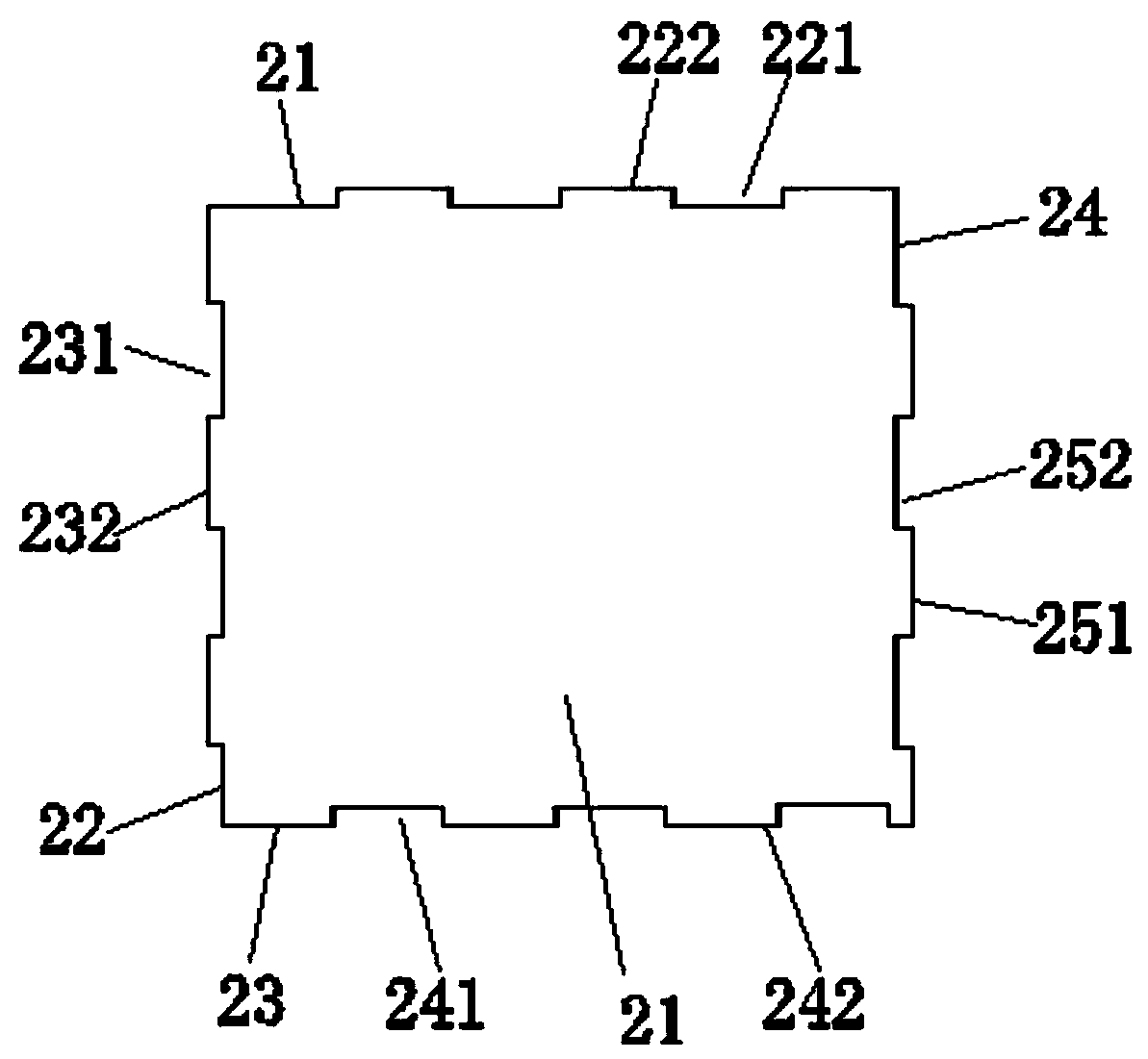

[0033] see Figure 1 to Figure 3 , the figure shows an assembled composite tile provided by Embodiment 1 of the present invention, which includes a tile 1 and a bottom mold 2, the bottom mold 2 is composited on the bottom of the tile 1, and the bottom mold 2 includes: a template 21; a splicing structure, It is arranged around the template 21, and the splicing structure includes a first splicing edge 22, a second splicing edge 23, a third splicing edge 24 and a fourth splicing edge 25 arranged in sequence, the first splicing edge 22 and the third splicing edge 24 are respectively Located on opposite sides of template 21, second splicing edge 23 and fourth splicing edge 25 are respectively positioned at another opposite two sides of template 21; The side 23 comprises a second splicing notch 231 and a second splicing block 232, the third splicing edge 24 comprises a third splicing notch 241 and a third splicing block 242; the fourth splicing edge 25 comprises a fourth splicing no...

Embodiment 2

[0043] see image 3, the figure shows a prefabricated composite tile provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first splicing notch 221 , the number of the first splicing block 222, the second splicing notch 231, the second splicing block 232, the third splicing notch 241, the third splicing block 242, the fourth splicing notch 251 and the fourth splicing block 252 is set to At least two; the bottom edge of the first splicing notch 221, the second splicing notch 231, the third splicing notch 241 and the fourth splicing notch 251 is consistent with the edge of the tile 1; the first splicing notch 221, the second splicing notch 251 The depth and width of the second joint notch 231 , the third joint notch 241 and the fourth joint notch 251 are the same. Through the setting of the above structure, there are two or more groups of splicing n...

Embodiment 3

[0045] see image 3 , the figure shows a prefabricated composite tile provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: along the plane direction of tile 1 , the first splicing block 222, the second splicing block 232, the third splicing block 242 and the fourth splicing block 252 all protrude from the ceramic tile 1; the first splicing block 222, the second splicing block 232, the third splicing block 242 and the The dimensions of the four splicing blocks 252 are consistent. The configuration of the above structure not only facilitates processing, but also improves the overall splicing effect and enhances the aesthetics.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap