Transmission mechanism-externally-arranged type ceramic double-core adjustable shrinkage cavity

A transmission mechanism, external technology, applied in the direction of engine components, valve devices, sliding valves, etc., can solve the problems of failure of adjustment function, short service life, leakage of transmission shaft, etc., and achieve reliable transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

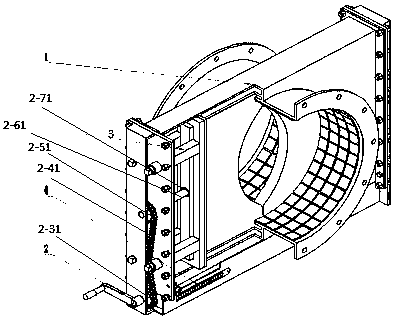

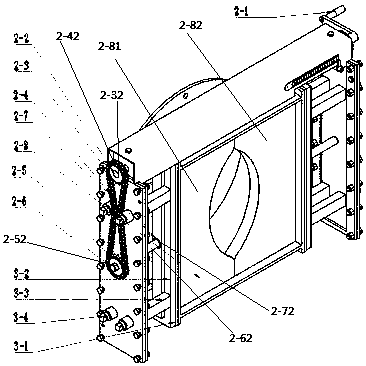

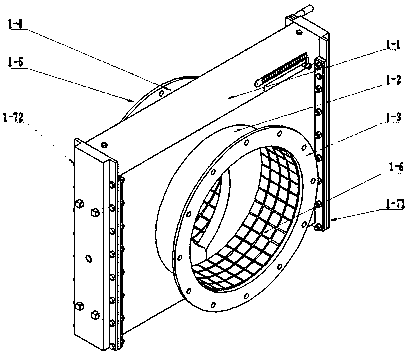

[0027] see Figure 1-4 The external ceramic double-core adjustable shrinkage hole of a transmission mechanism shown, the adjustable shrinkage

[0028] The hole is installed on the pulverized coal delivery pipeline of the thermal power plant, and it is characterized in that it includes a box assembly 1, a transmission mechanism assembly 2, a sealing assembly 3, and a shrinkage cavity adjustment indicator device 4. The transmission mechanism assembly 2 is set on the box assembly 1, and the transmission The mechanism assembly 2 includes a screw rod 2-6 and a wear-resistant alloy gate 2-8, and the wear-resistant alloy gate 2-8 includes a right wear-resistant alloy gate 2-81 and a left wear-resistant alloy gate 2-82 , the transmission component 2 controls the right wear-resistant al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com