Spray condensing device for normal-pressure heat pump evaporator

A heat pump evaporator and condensing device technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problem of low heat transfer efficiency of the air-water partition, achieve stable condensation effect, reduce cost, and improve heat transfer efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

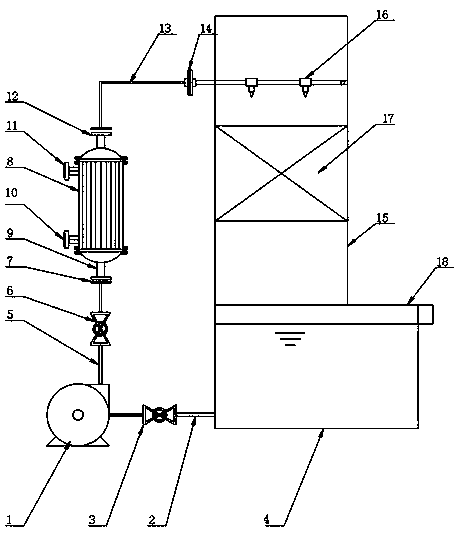

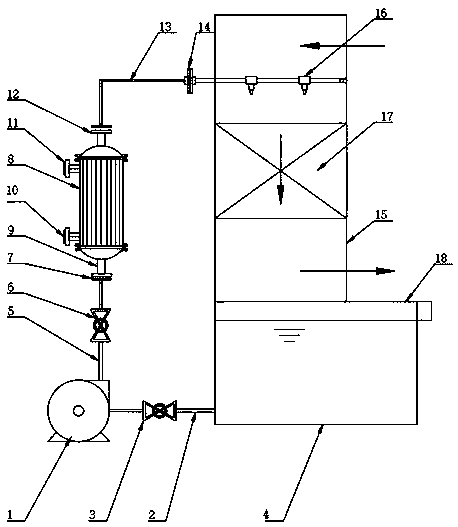

[0033] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a spray condensing device for an atmospheric heat pump evaporator, including a spray water pump 1, the water inlet end of the spray water pump 1 is connected to a water inlet pipe 2, and one end of the water inlet pipe 2 is connected to a condensation tower 4;

[0034] The water outlet end of the spray water pump 1 is connected with the water outlet pipe 5, the middle part of the water inlet pipe 2 is embedded with the water inlet valve 3, and the middle part of the water outlet pipe 5 is embedded with the water outlet valve 6, so that the spray water pump 1 can be disassembled later for easy maintenance, and the water outlet pipe One end of 5 is connected with a water inlet flange 7, and the water inlet flange 7 is connected with the heat exchanger 8, and the bottom end of the heat exchanger 8 is provided with a water inlet pipe 9, and the water inlet pipe 9 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com