Roller hearth heating furnace roller intelligent monitor

A roller hearth furnace and monitor technology, applied in lighting and heating equipment, furnaces, furnace components, etc., to achieve the effect of clear normal and fault states, comprehensive detection and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

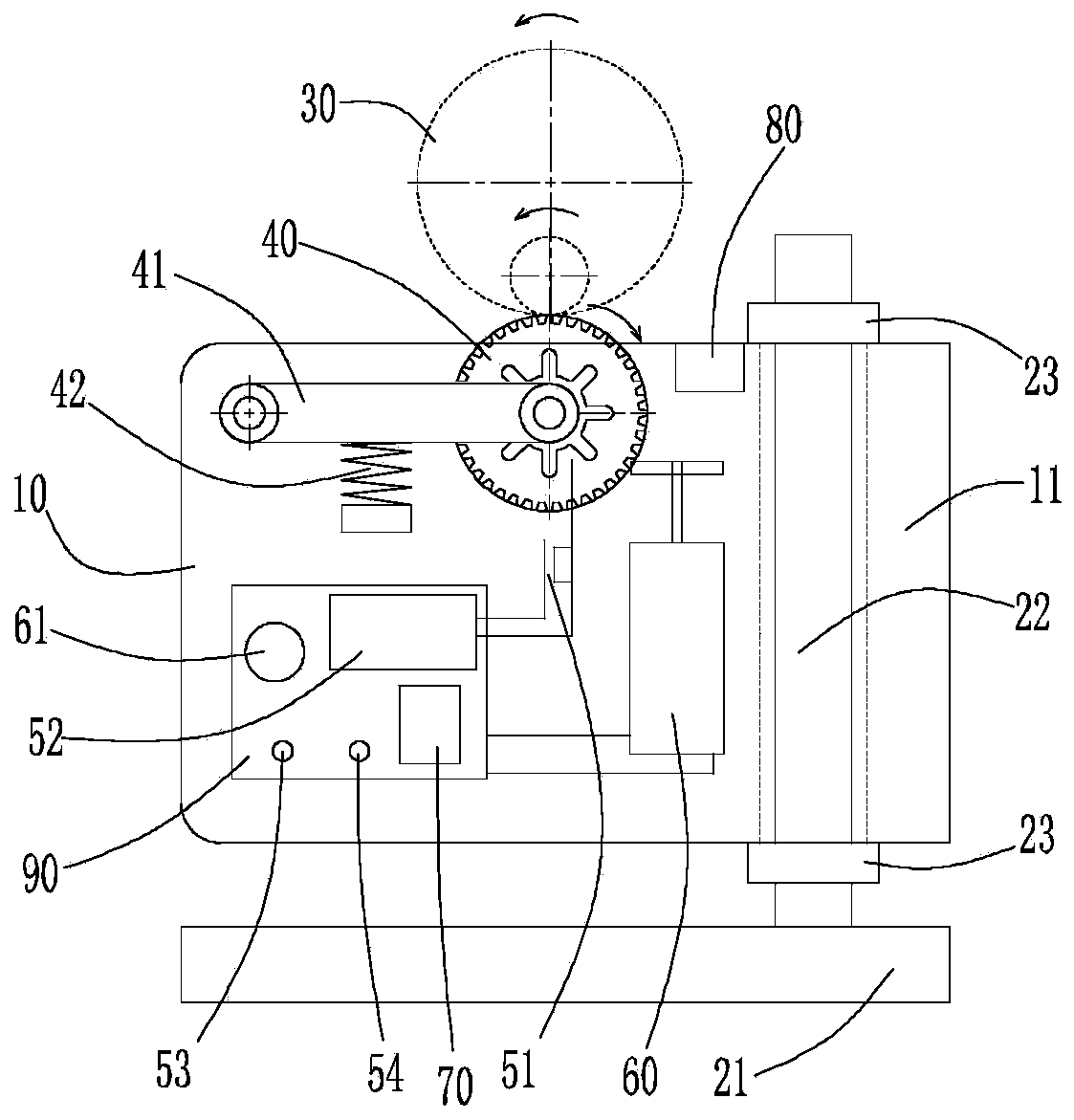

[0031] like figure 1 As shown, Embodiment 1 of the present application provides an intelligent monitor for rollers in a roller hearth heating furnace, which can be used for monitoring the working status of rollers of various shapes. The monitor of the present invention can be installed at the non-drive end of the roller to monitor the running state of the roller. The intelligent monitor is composed of a monitor body 10 , a magnetic chuck 21 with a guide stud 22 and a lock nut 23 , etc., and the guide stud 22 is installed on the magnetic chuck 21 . Wherein, the magnetic sucker 21 can be adsorbed on the equipment (steel) shell near the monitored roller bar 30 nearby, the monitor body 10 can move up and down along the guide stud 22, and the lock nut 23 locks the monitor body 10 in the guide in place on the stud 22. The composite roller 40 on the fixed monitoring body 10 is close to the roller surface under the monitored roller 30 and rotates with the roller under the action of ...

Embodiment 2

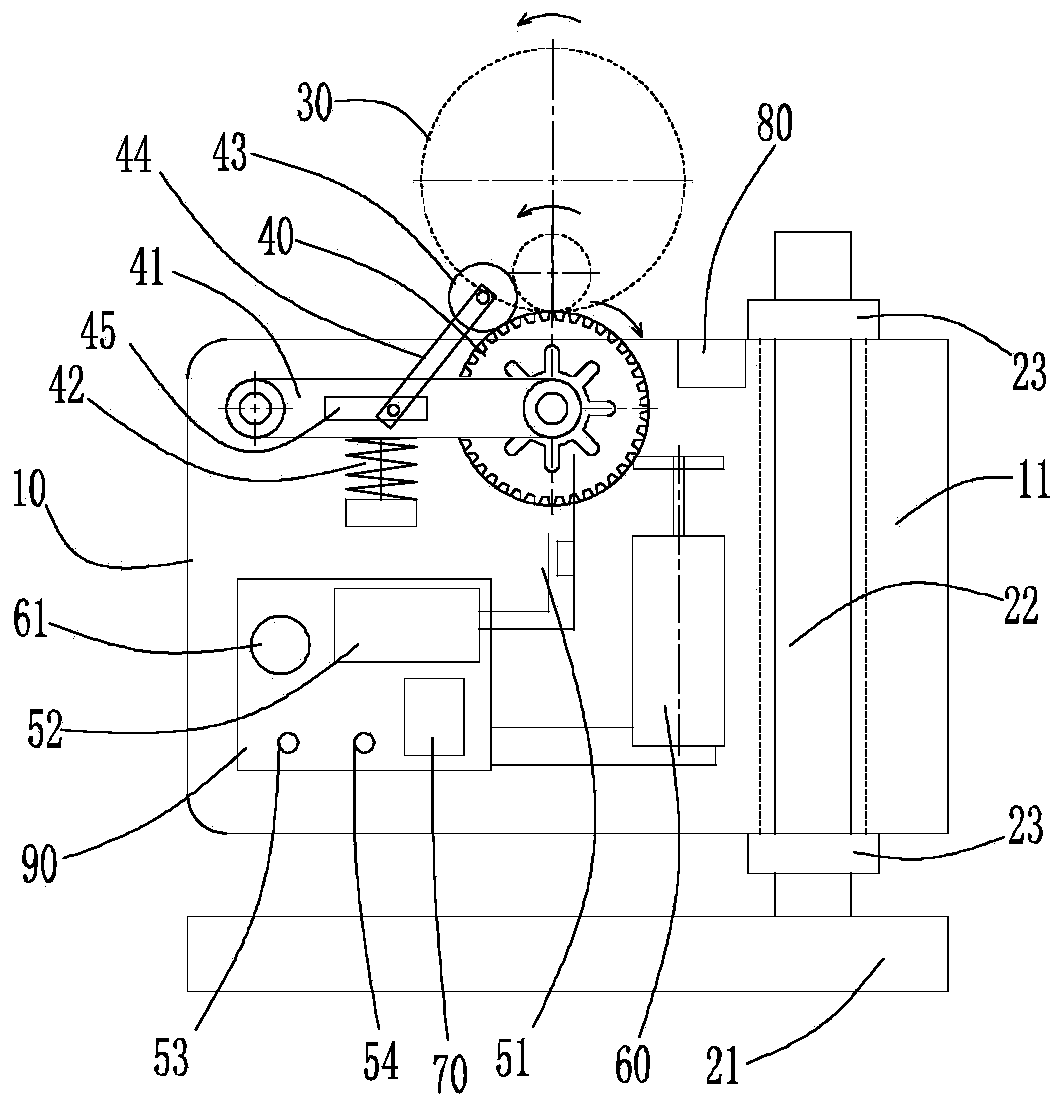

[0042] like figure 2 As shown, the difference between Embodiment 2 of the present application and Embodiment 1 is that an adjustment mechanism is arranged above the swing mechanism, and its adjustment wheel 43 is mounted on the elongated through hole 45 of the composite roller swing rod 41 through a connecting rod 44 through a bolt. Up, the lower end of the connecting rod 44 is fixed on the elongated through hole 45 and its position is adjustable, so that the position of the adjustment wheel 43 at its upper end can be adjusted up and down, and the position can be adjusted along the elongated through hole 45 to realize the adjustment of the adjustment wheel 43. Moving up and down. When the position is adjusted by the guide stud 22 of the fixing mechanism, when the compound roller 40 and the monitored roller bar 30 cannot be closely attached, the position of the adjusting wheel 43 can be fine-tuned to make it closely fit the roller bar and the compound roller 40 , Increase fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com