Vertical single-optical-element rotary Mueller matrix imaging measuring device and method

A Mueller matrix and optical element technology, applied in the field of measurement devices for vertical single optical element rotating Mueller matrix imaging, can solve the problems of low measurement accuracy and complicated operation, and achieve fast measurement process, ensure accuracy, and fast The effect of precise measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

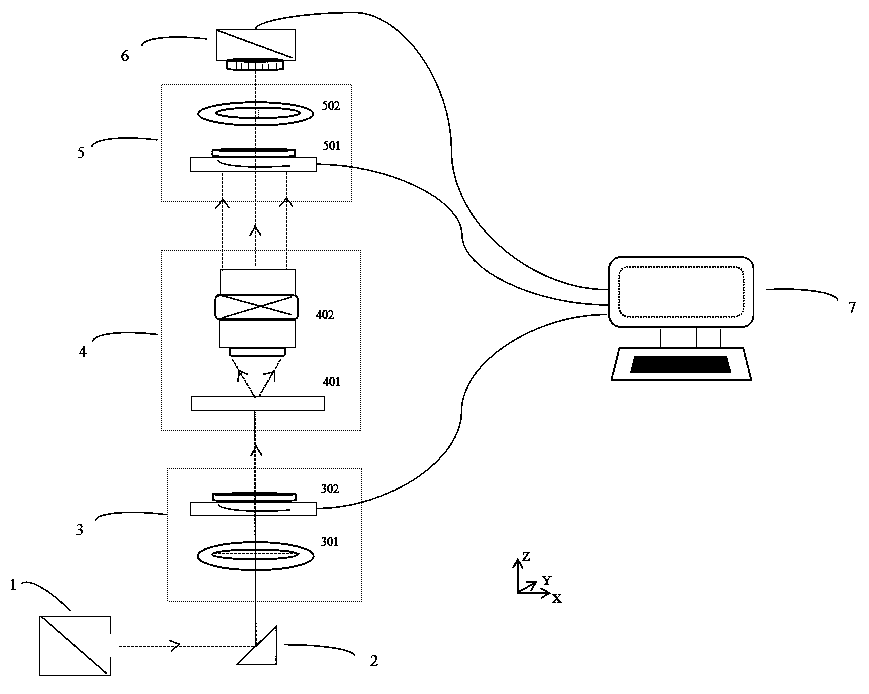

[0029] refer to figure 1 , the present invention will be further described in detail below in conjunction with specific embodiments.

[0030] The rotation of a single optical element in the present invention means that during the working process of a measurement device for Mueller matrix imaging provided by the present invention, the first compensator 302 in the polarization modulation unit 3 is set to have fixed Rotation angle, the second compensator 501 in the polarization demodulation unit 5 is set to rotate at a constant speed at a constant speed.

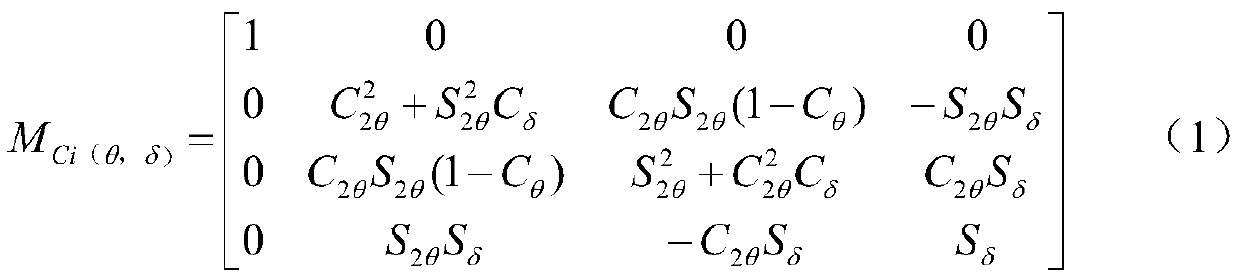

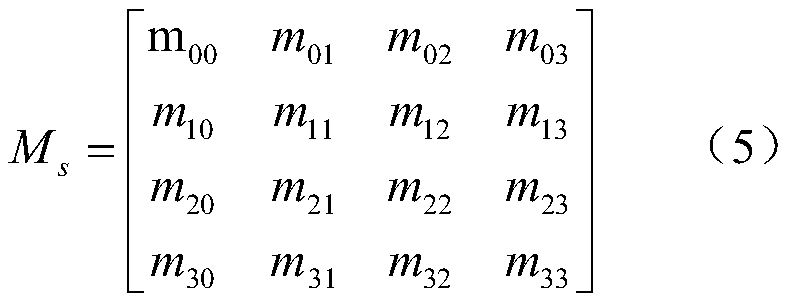

[0031] The non-normalized Muller matrix of the sample to be tested in the present invention is expressed as:

[0032]

[0033] Among them, M s represents the unnormalized Mueller matrix of the sample, m ij (i, j=0, 1, 2, 3) represent 16 elements of the unnormalized Mueller matrix of the sample to be tested.

[0034] The non-normalized Mueller matrix of the sample to be measured can be obtained by summing the Stokes vecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com