Non-contact measuring device and method for dynamic tension and twist of yarn

A non-contact measurement and tension technology, used in measurement devices, textiles and papermaking, instruments, etc., can solve the problems of time-consuming and laborious operation, inconvenient installation, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

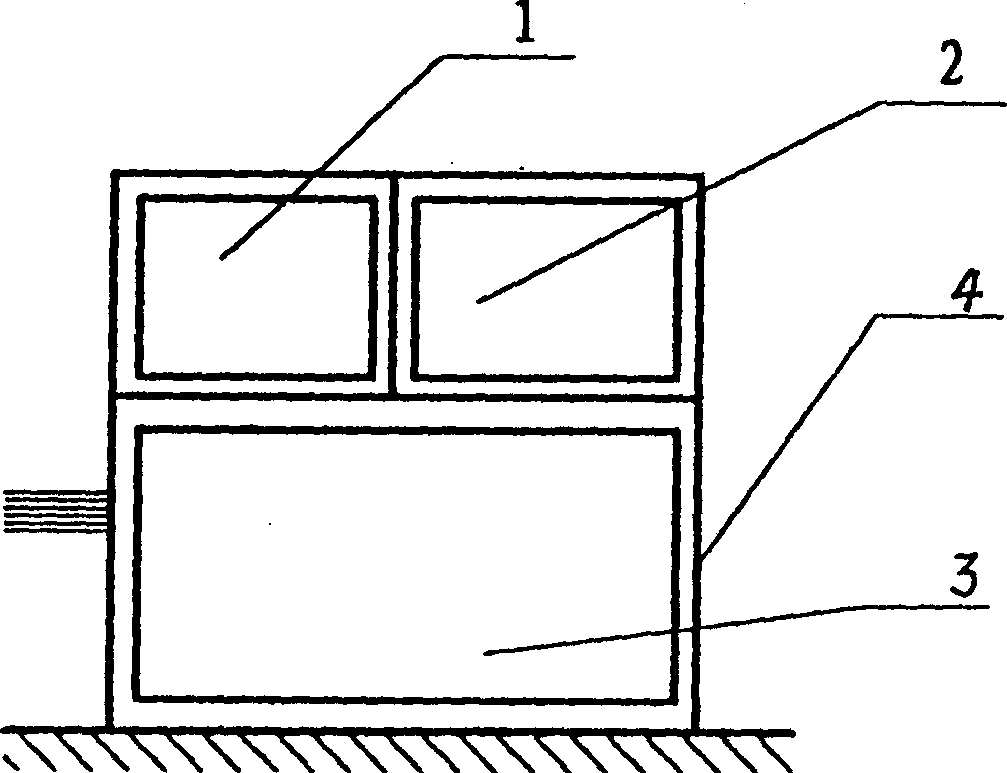

Embodiment 1

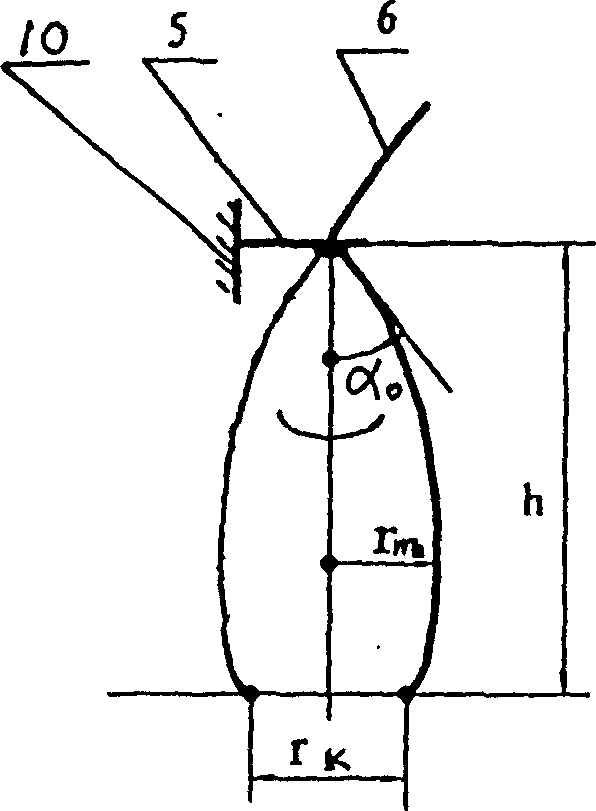

[0078] Example 1 - Measuring Spinning Dynamic Tension. There are two calculation formulas: ①P=T(ω / λ) 2 [1+0.5(λr m ) 2 ]②P=Tω 2 [πcos(α 0 / 2) / (2λKcosα 0 )] 2 . In the above formula: λ=[arcsin(r k / r m )] / h, K = ∫ 0 π / 2 ( 1 - k 2 sin 2 φ ) - 1 / 2 dφ , k = ( 1 - cos α 0 ) / ( 1 + ...

Embodiment 2

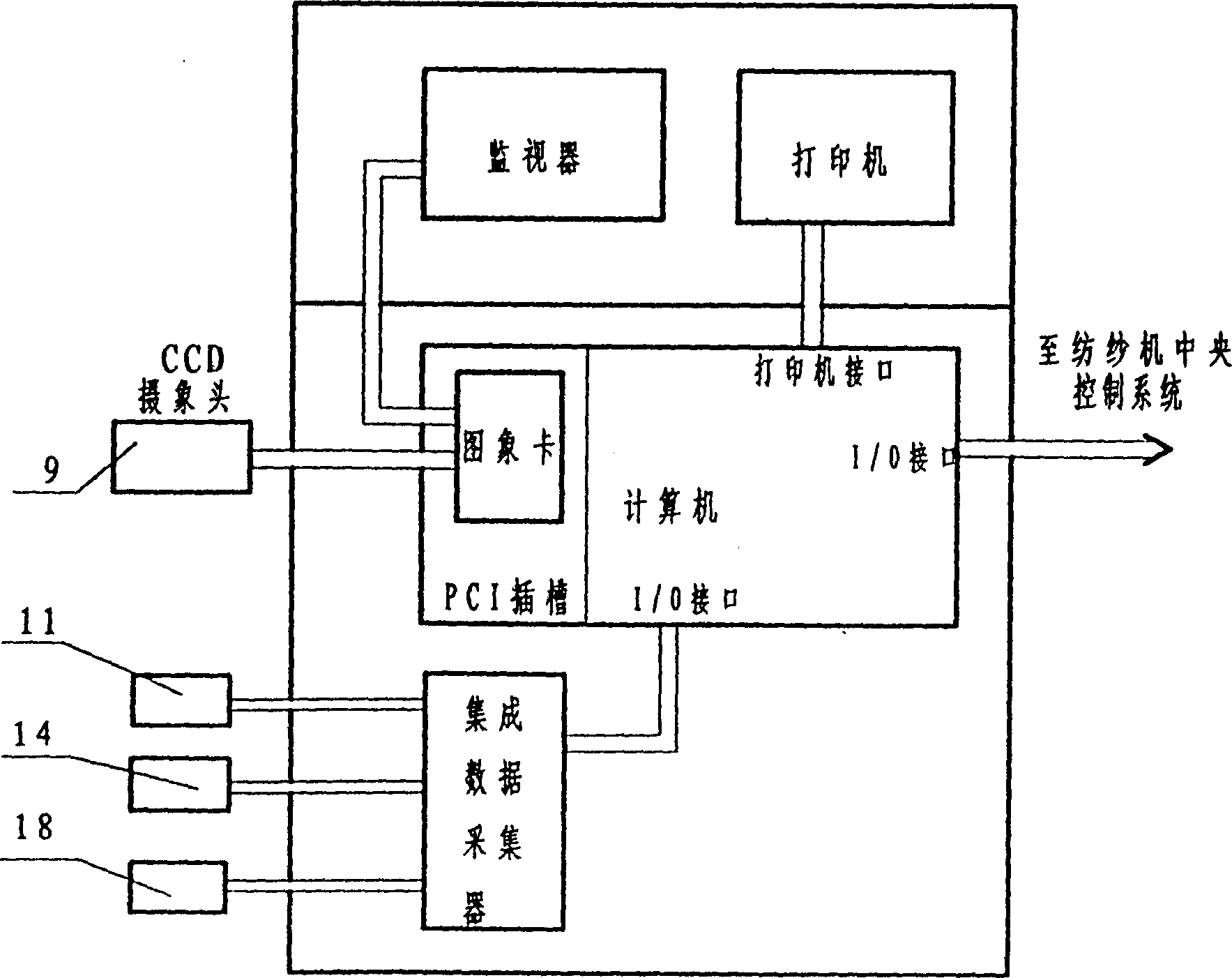

[0086] Embodiment 2 - automatic measurement of spinning dynamic twist with the method and device of the present invention. Method for automatic measurement of spinning dynamic twist:

[0087] 1. The speed sensor 18 is installed on the front roller of the spinning machine to measure the speed n of the front roller d (rev / min), then the yarn longitudinal velocity v=πn d D (m / min), wherein D is the front roller diameter (m); the speed sensor 14 is mounted on the ring plate to measure the speed n (rev / min) of the traveler.

[0088] 2. The measurement signals of the rotational speed sensor 14 and the rotational speed sensor 18 are input into the computer through the integrated data collector, and the computer automatically calculates the yarn twist at this moment according to the following formula: t w =n / v=n / (πnd D) (twist / m).

[0089] 3. The results are displayed on the display screen of the monitor, or printed out.

[0090] 25tex cotton yarn is spun on the FA506 spinning fra...

Embodiment 3

[0091] Embodiment 3--measuring the twist of spun yarn with the method of the present invention and its device. Method for measuring twist and diameter of spun yarn:

[0092] 1. Install the yarn to be tested on the yarn clamping frame, stretch the yarn tightly, and pay attention not to pull the yarn too tight or too loose.

[0093] 2. The CCD camera captures the yarn image, and the image information is stored in the computer through the image card.

[0094] 3. The image information in the computer is processed by smoothing, denoising, thresholding, etc. to extract image feature parameters: twist number N, yarn image length L 0 , Yarn image diameter d 0 .

[0095] 4. Carry out the calibration experiment, that is: any actual yarn length value is given, the yarn length value on the image is measured, and the equivalent coefficient D is calculated according to the following formula 2 = actual yarn length value / yarn length value on the image.

[0096] 5. Calculate the actual tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com