Device and method for thermal or thermo-chemical treatment of material

A technology for thermochemical treatment and cathode materials, which is applied to calcination devices and calcination fields, and can solve problems such as long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

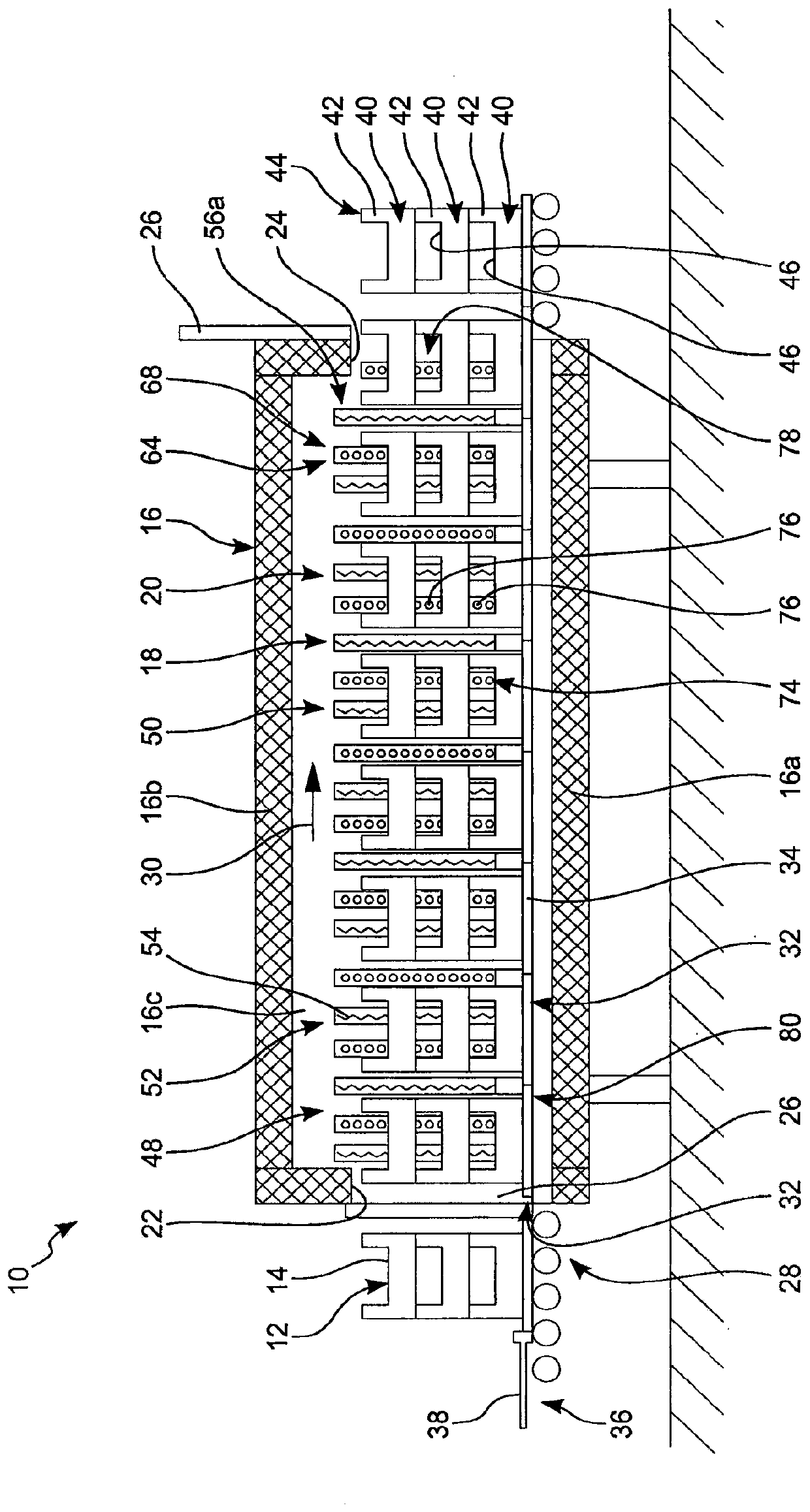

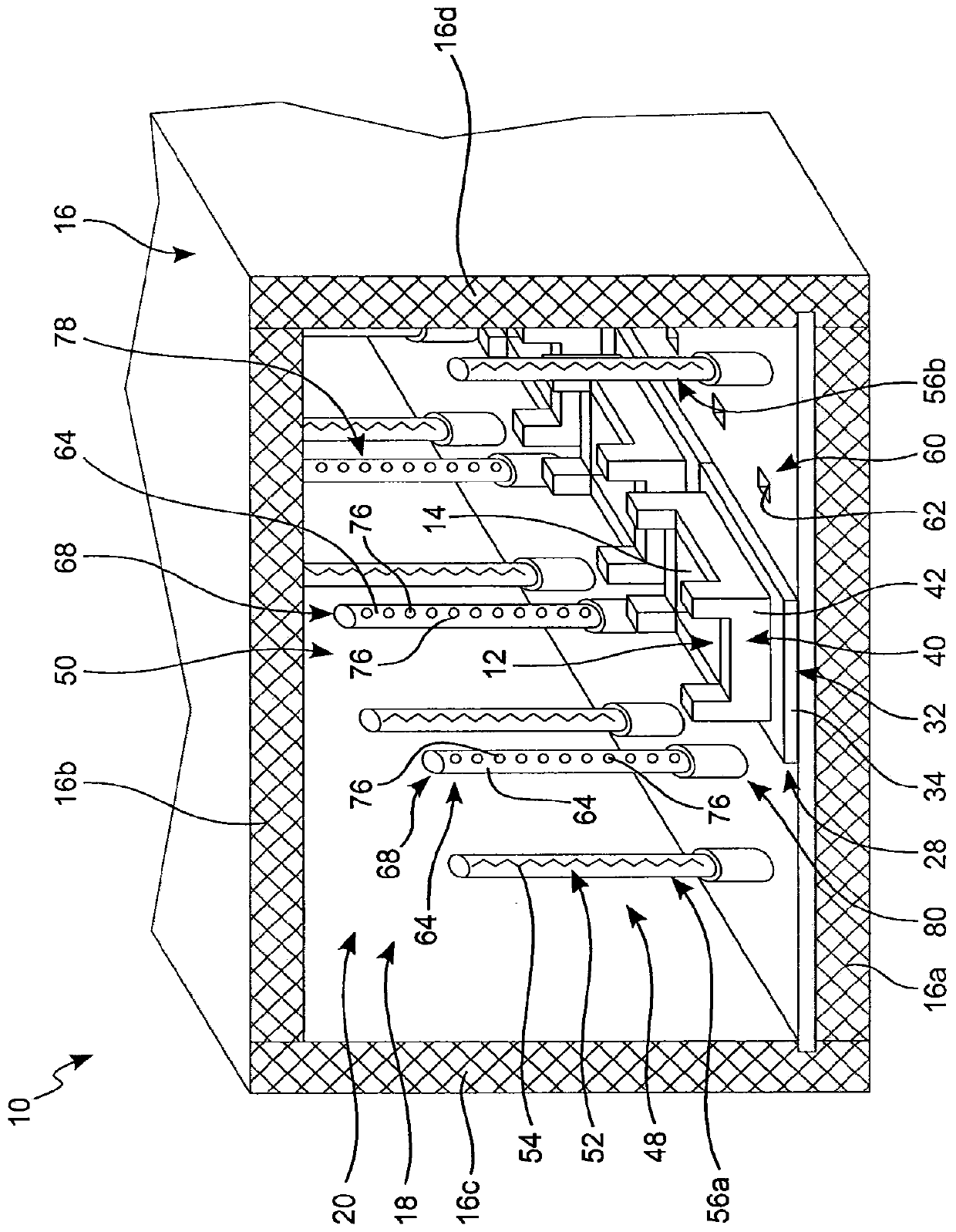

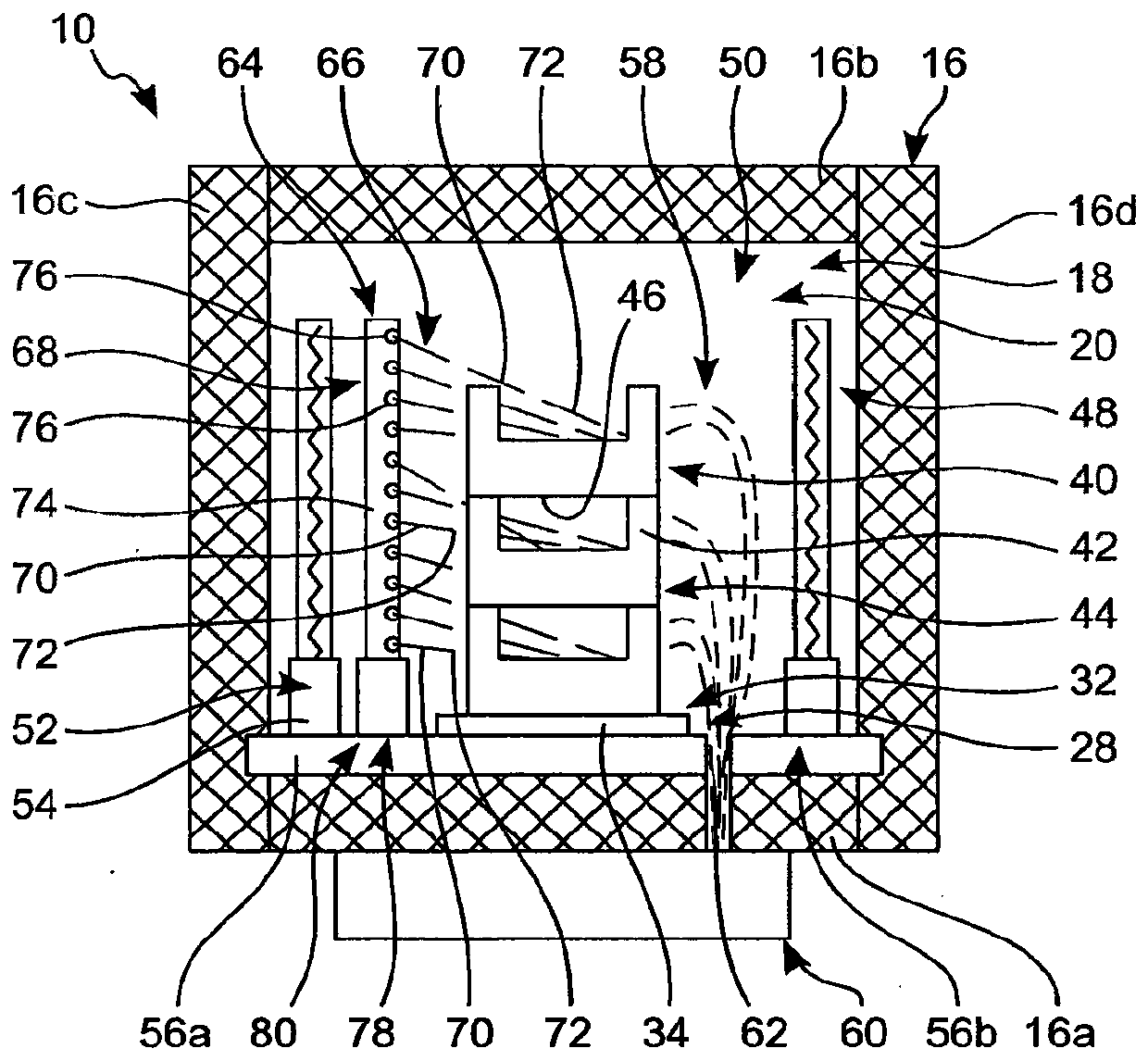

[0065] First refer to Figure 1 to Figure 4 . Shown at 10 in the figure is an apparatus for heat-treating material 12 . The device 10 will be referred to below as a furnace 10 for convenience.

[0066] The material 12 can be, for example, the aforementioned battery cathode material 14 which must be calcined during the production of the battery by heat treatment in the furnace 10 .

[0067] The furnace 10 comprises a housing 16 having a bottom 16a, a roof 16b and two vertical side walls 16c and 16d, which defines an interior space 18 in which a process chamber 20 is located. The housing 16 thus forms the housing of the process chamber 20 . Inner space 18 of furnace 10 may optionally be delimited by a separate housing surrounded by housing 16 . from figure 1 As can be seen in the figure, the process chamber 20 extends between an inlet 22 and an outlet 24 of the housing 16, which can be closed by means of a door 26, respectively. Alternatively, an open inlet 22 and an open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com