High-speed screening and analysis system for reaction optimization

An analysis system and reaction technology, applied to laboratory containers, chemical instruments and methods, laboratory utensils, etc., can solve problems such as high cost, achieve the effects of avoiding external pollution, uniform concentration, and improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Hereinafter, a high-speed screening analysis system 100 implementing an example according to the present invention will be described as an example of a high-speed screening analysis system for optimizing a heavy metal-organic ligand reaction.

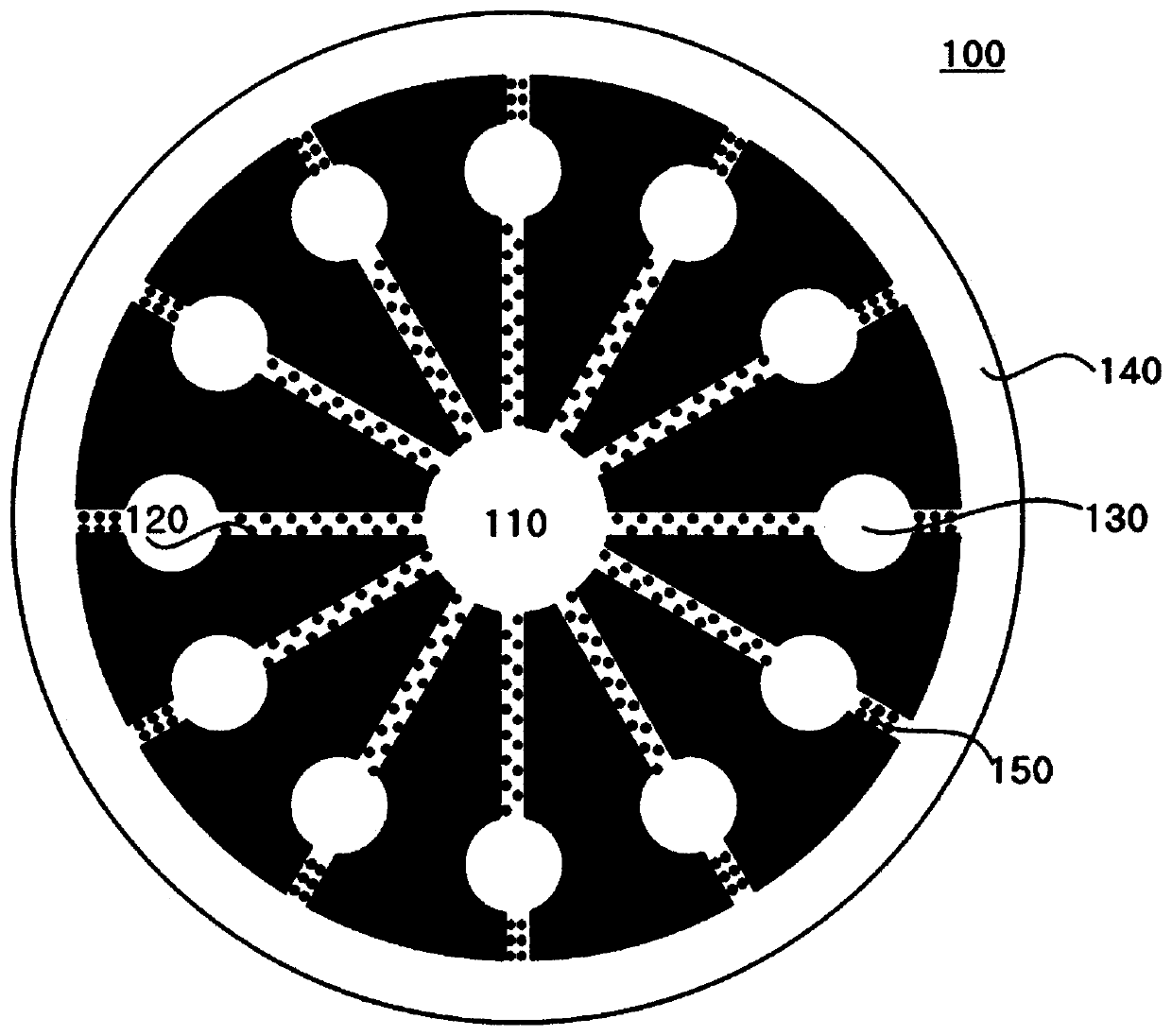

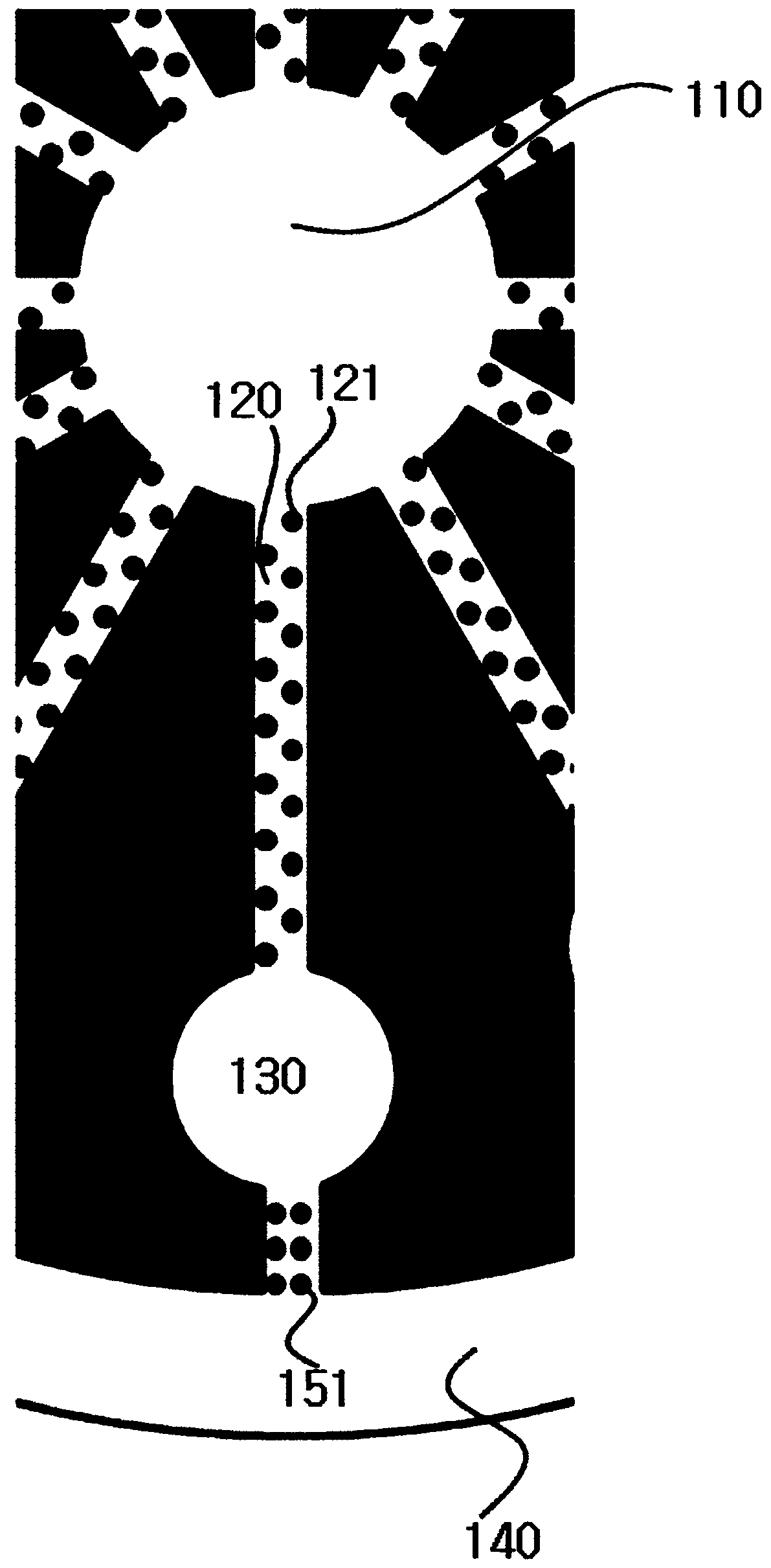

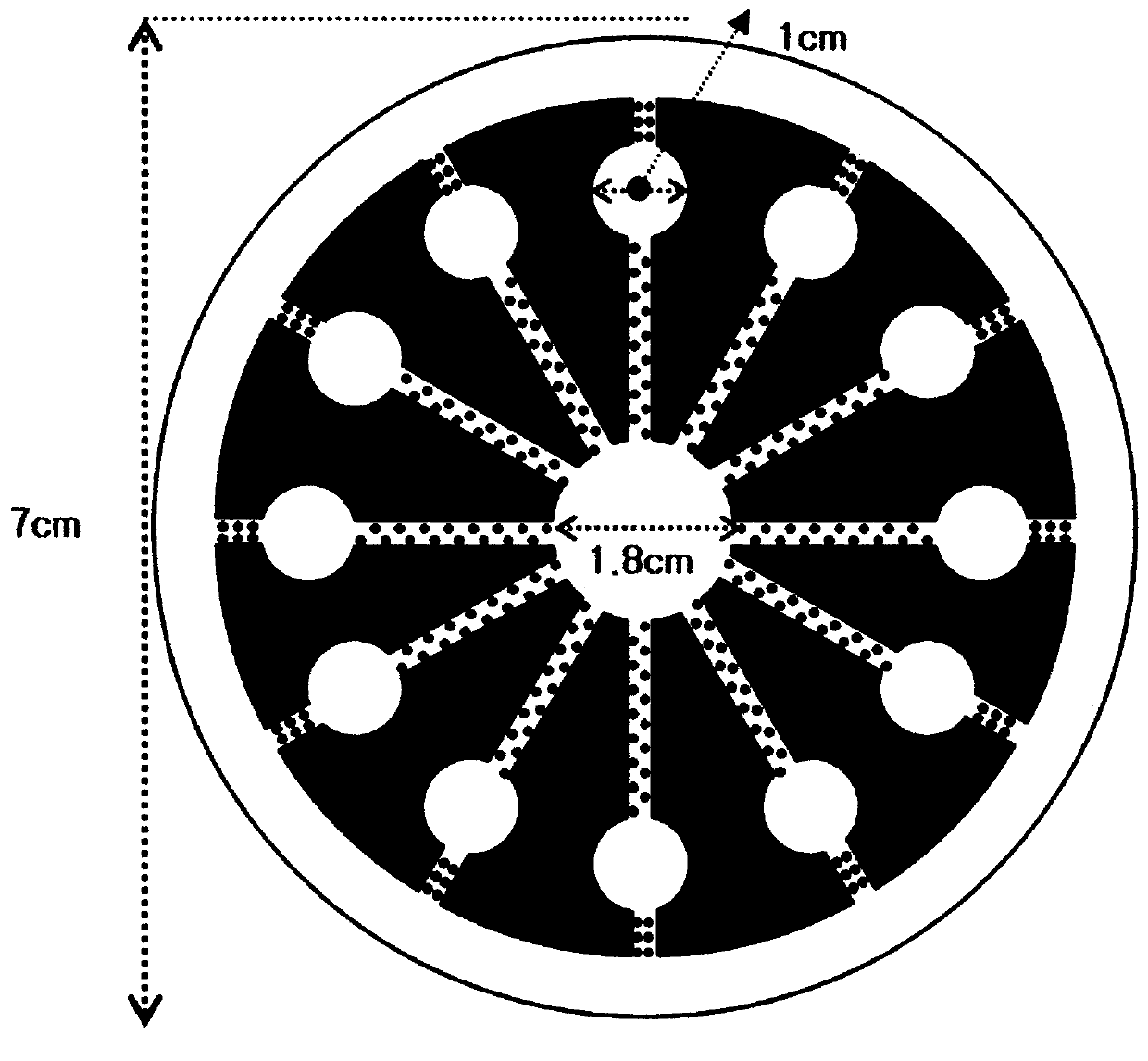

[0059] The high-speed screening assay system 100 may be implemented as a disc-based system. One sample injection part 110 may be provided at the center of the paper disc, and twelve reactant application parts 130 radially provided around the sample injection part 110 may be provided. Twelve injection microchannels 120 may be provided, and each injection microchannel 120 may connect the sample injection part 110 with each reactant coating part 130 . The absorbing part 140 may be provided along the edge of the paper disc. Twelve discharge microchannels 150 may be provided, and each discharge microchannel may connect each reactant coating part 130 and the absorption part 140 .

[0060] The high-speed screening analysis system 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com