Start-up preparation method of hydrocracking unit

A technology of hydrocracking and preparation method, which is applied in the direction of start-up of hydroprocessing operation, petroleum industry, and treatment of hydrocarbon oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

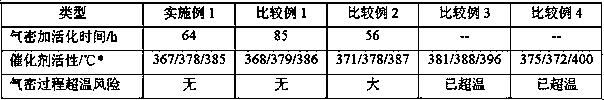

Examples

Embodiment 1

[0045] A hydrogenation unit is equipped with an external presulfurization type II active center hydrocracking supporting catalyst. The properties of the catalyst are shown in Table 2. The system design pressure is 16MPa. Preparations for start of work include:

[0046] (1) Introduce nitrogen into the reaction system, and perform low-pressure airtightness at 1.0Pa, 3.0MPa, and 5.0MPa in sequence;

[0047] (2) After the airtightness is qualified, reduce the system pressure to 3.7MPa, introduce hydrogen to keep the pressure constant at 4.6MPa, and then raise the temperature of the catalyst bed to 100°C for 7 hours; the heating rate is 20°C / h;

[0048] (3) Keep the pressure constant, and continue to raise the temperature of the catalyst bed to 120°C at a rate of ~7°C / h for 7 hours;

[0049] (4) Continue to raise the catalyst bed temperature to 133°C at a rate of ~7°C / h, and keep the temperature constant;

[0050] (5) When the reactor wall temperature is higher than 120°C, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com