Length-variable flexible pipe and device using same

A length-changing, flexible tube technology, applied in the direction of fluid pressure actuators, etc., can solve problems such as difficulty in compensation through control, difficulty in force control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

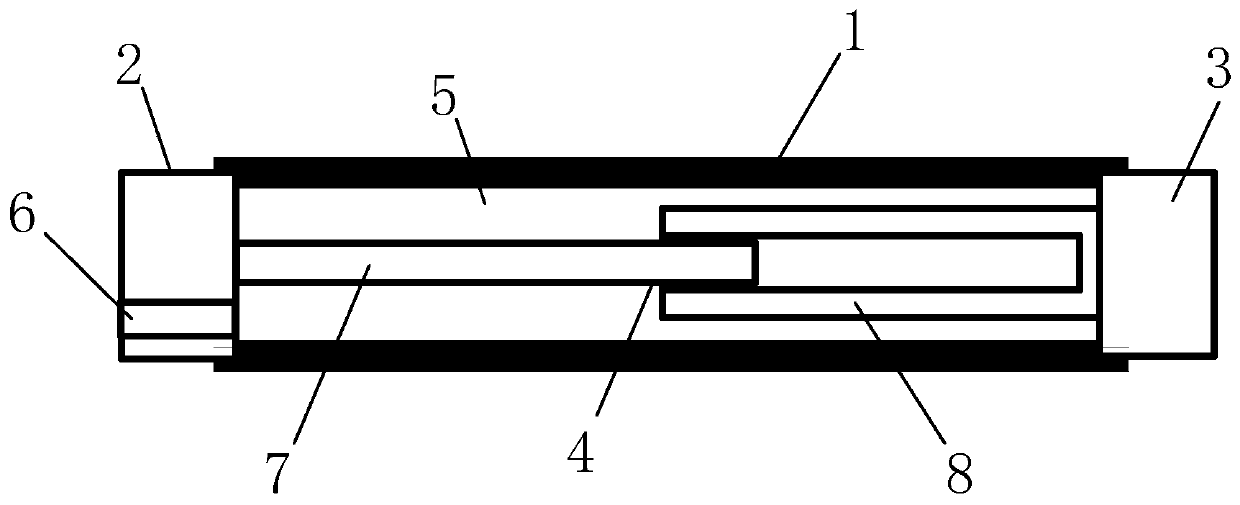

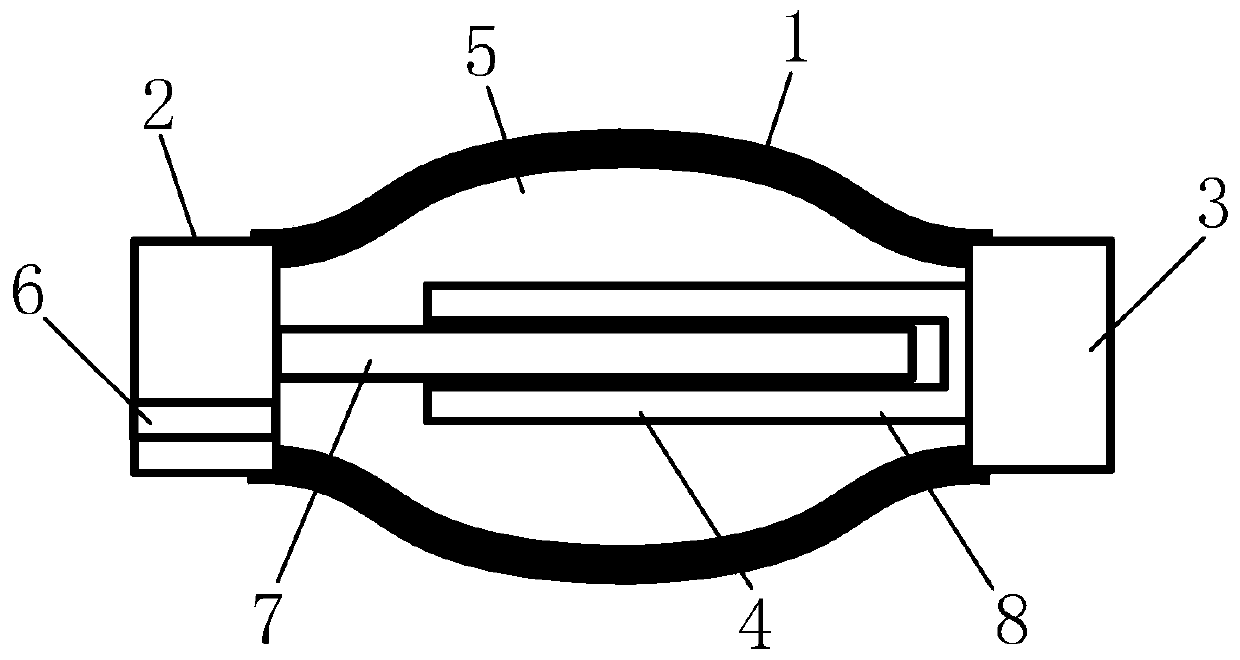

[0033] Please also refer to figure 1 as well as figure 2 As shown, the preferred embodiment of the length-changing flexible pipe of the present invention includes a flexible pipe 1 and a left end positioning part 2 and a right end positioning part 3 fixed at both ends of the flexible pipe 1 .

[0034] The flexible pipe 1 and the left-end locating piece 2 and the right-end locating piece 3 at both ends form a hollow cavity 5 , and a telescoping mechanism 4 is arranged in the cavity 5 . The telescopic mechanism 4 can change the length of the flexible pipe 1 in the length direction. A part or all of the telescopic mechanism 4 is made of rigid material, which can restrain the bending deformation of the flexible tube 1 in directions other than the longitudinal direction.

[0035] A through hole 6 is provided on the left end positioning part 2 or the right end positioning part 3 . The through hole 6 in this embodiment is provided on the left end positioning member 2 . The thro...

Embodiment 2

[0038] Please also refer to figure 1 as well as figure 2 As shown, as the second embodiment of the length-changing flexible pipe of the present invention, the telescopic mechanism 4 includes a left-end fixing piece and a right-end fixing piece, the left-end fixing piece is connected with the left-end locating piece 2, and the right-end fixing piece is connected with the right-end locating piece 3 , the left-end fixing part and the right-end fixing part can move relatively in the length direction of the flexible pipe 1 , and constrain each other in directions other than the length direction of the flexible pipe 1 .

[0039] In this embodiment, the left-end fixing member and the right-end fixing member are respectively a sliding rod 7 and a sleeve 8, the sliding rod 7 and the sleeve 8 are connected by a sliding fit, and one end of the sliding rod 7 is connected to the left-end positioning member 2, The other end is sleeved in the inner cavity of the sleeve 8 , and one end of ...

Embodiment 3

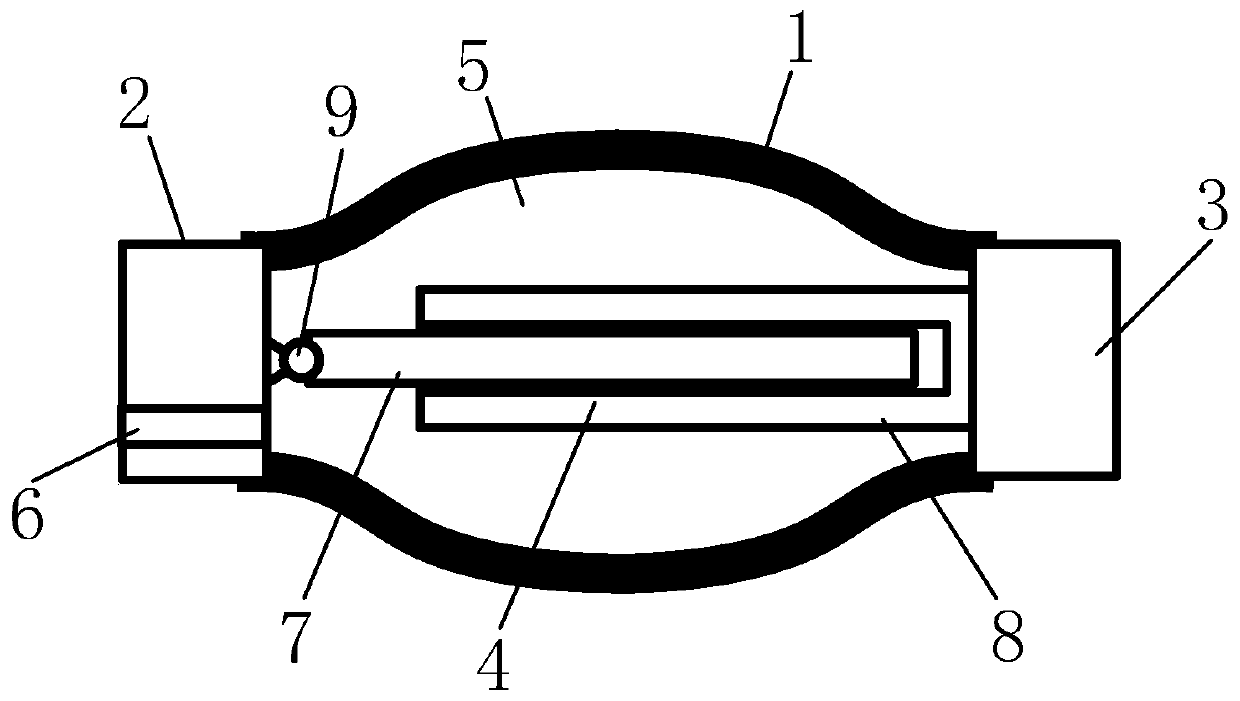

[0042] The fixing pieces at both ends of the telescoping mechanism 4 are connected with the positioning pieces at both ends of the flexible pipe 1 by hinges. Please refer to image 3 As shown, the difference between this embodiment and Embodiment 2 is that a hinge 9 is provided at the connection between the left end locating member 2 and the left end fixing member (i.e. the slide bar 7), so that the left end locating member 2 has a certain degree of freedom of rotation, which facilitates The connection between the left end locator 2 and other components is fixed. Similarly, the connection between the right end positioning part 3 and the right end positioning part (that is, the sleeve 8 ) can also be set as a hinge connection. Other structures and functions are the same as those in Embodiment 2 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com