Off-line programming post-code conversion method and dual-robot collaborative intelligent manufacturing system and method based on the method

A technology of code conversion and offline programming, which is applied in the field of dual-robot collaborative intelligent manufacturing systems, can solve the problems of lack of dual-robot simulation and collaborative control functions, inability to coordinate trajectory planning and offline programming of dual-robots, and inability to achieve efficient collaborative intelligent manufacturing. Achieve the effects of improving work accuracy and programming efficiency, high adaptability, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

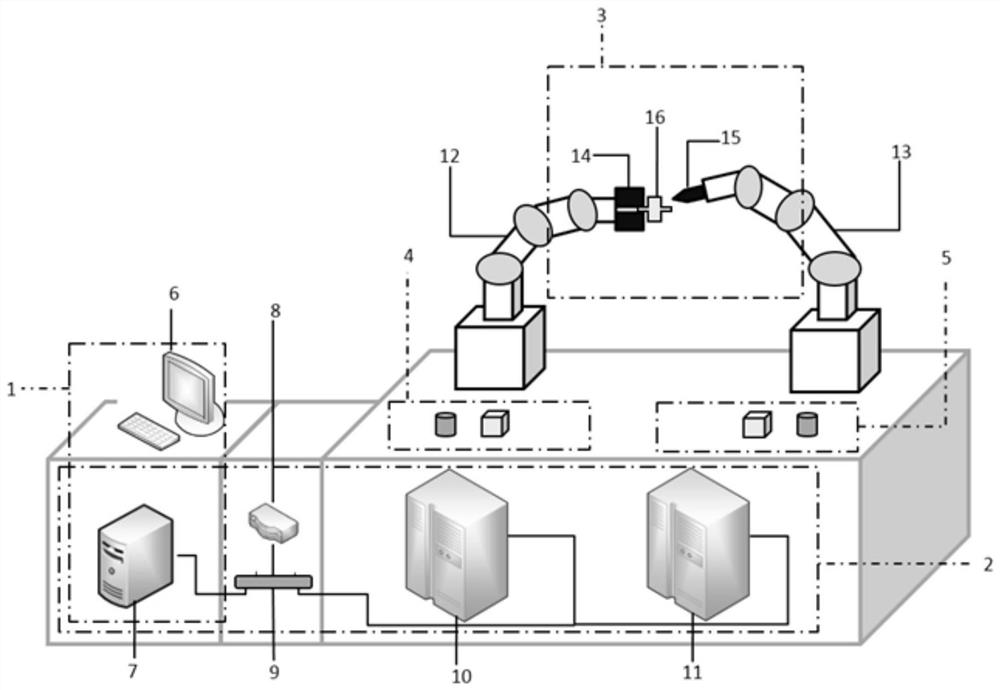

[0055] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

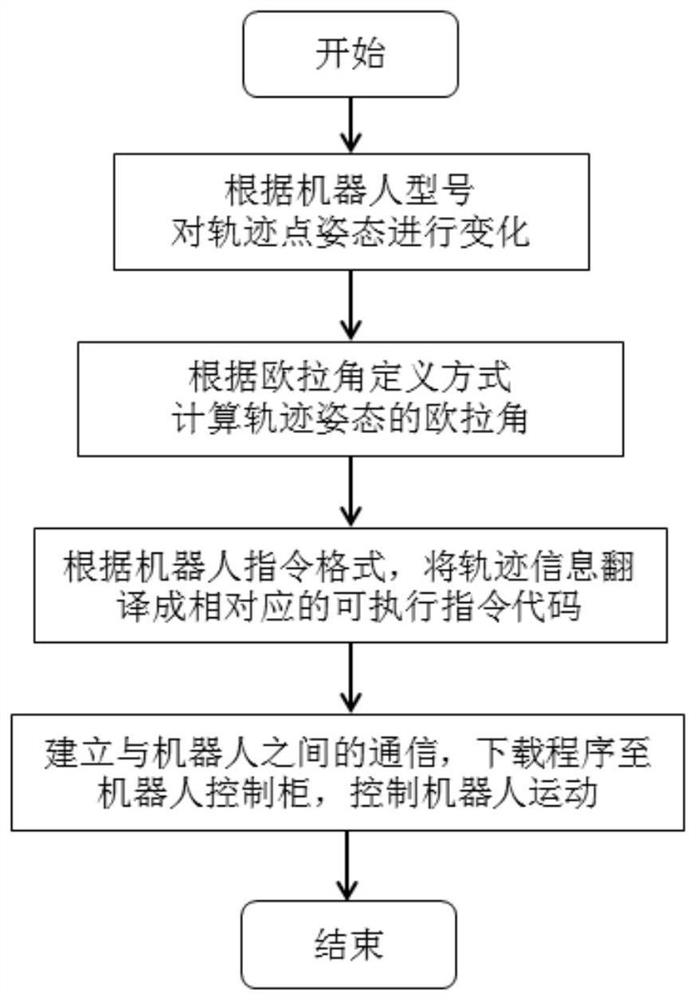

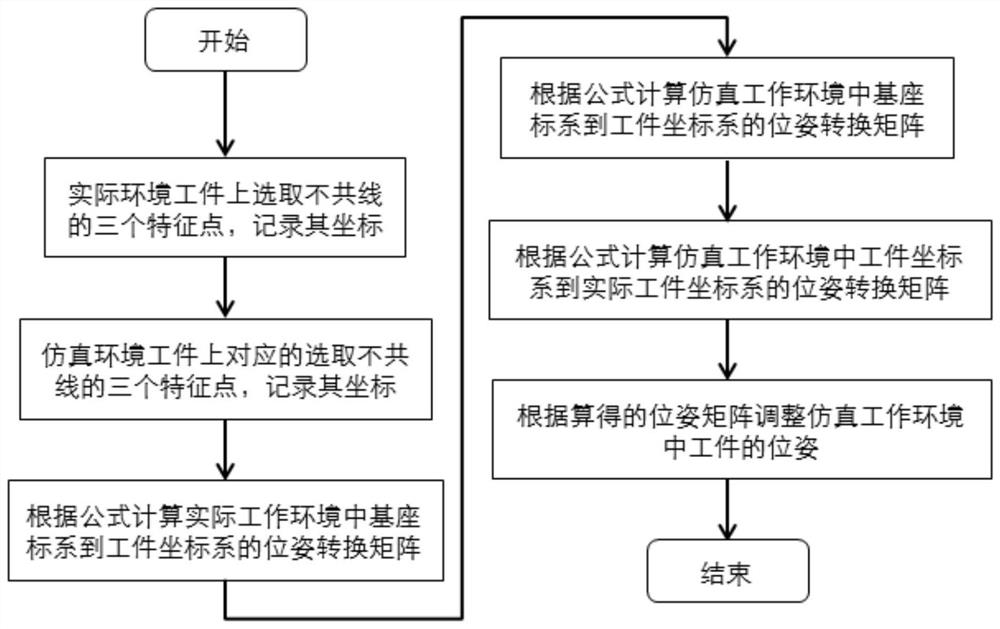

[0056] refer to figure 1 , post-code conversion after offline programming is to perform corresponding Euler angle transformation on the trajectory of the simulated robot and convert it into a corresponding instruction set according to the actual robot brand model used, so as to control the physical robot to complete the processing; and then perform post-code Editing and communication, that is, perform command editing, modification operations, file access on the post-code, and establish communication with multiple robots, so that the collaborative intelligent manufacturing in the simulation environment can be reproduced in the actual working environment.

[0057] Such as figure 1 As shown, combined with the example of workpiece processing, the post-code conversion of the present invention adopts the trajectory attitude information conversion met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com