Automatic magnet magnetizer

A magnetizing machine, automatic technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of low production efficiency of magnets, low efficiency of magnetization of magnetizers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

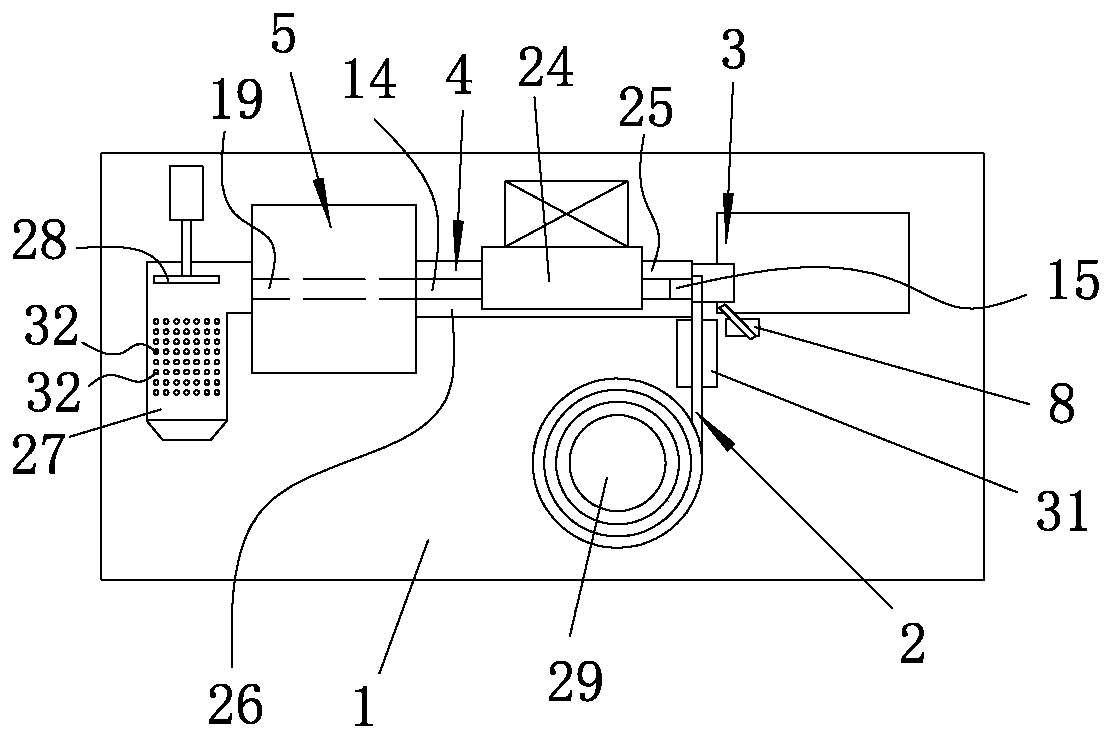

[0030] refer to Figure 1-Figure 3 , a kind of magnet automatic magnetizing machine of the present invention, comprises machine platform 1, the feeding mechanism 2 that is installed on the machine platform 1, transfer mechanism 3, guiding mechanism 4 and magnetizing mechanism 5, feeding mechanism 2 automatically supplies The external magnetizer, the transfer mechanism 3 is used to transfer the magnetizer supplied by the feeding mechanism 2 to the guide mechanism 4 and automatically move into the magnetization mechanism 5 under the guidance of the guide mechanism 4, and the magnetization mechanism 5 charges the magnetizer. Magnetism makes the magnetoconductor a magnet.

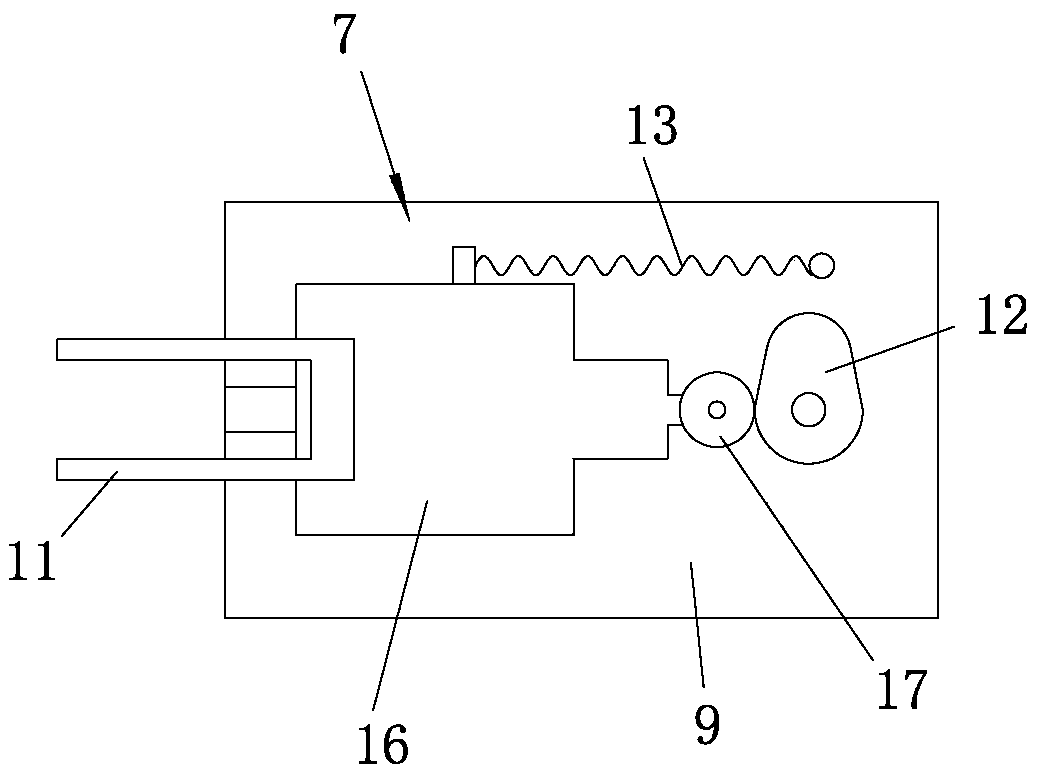

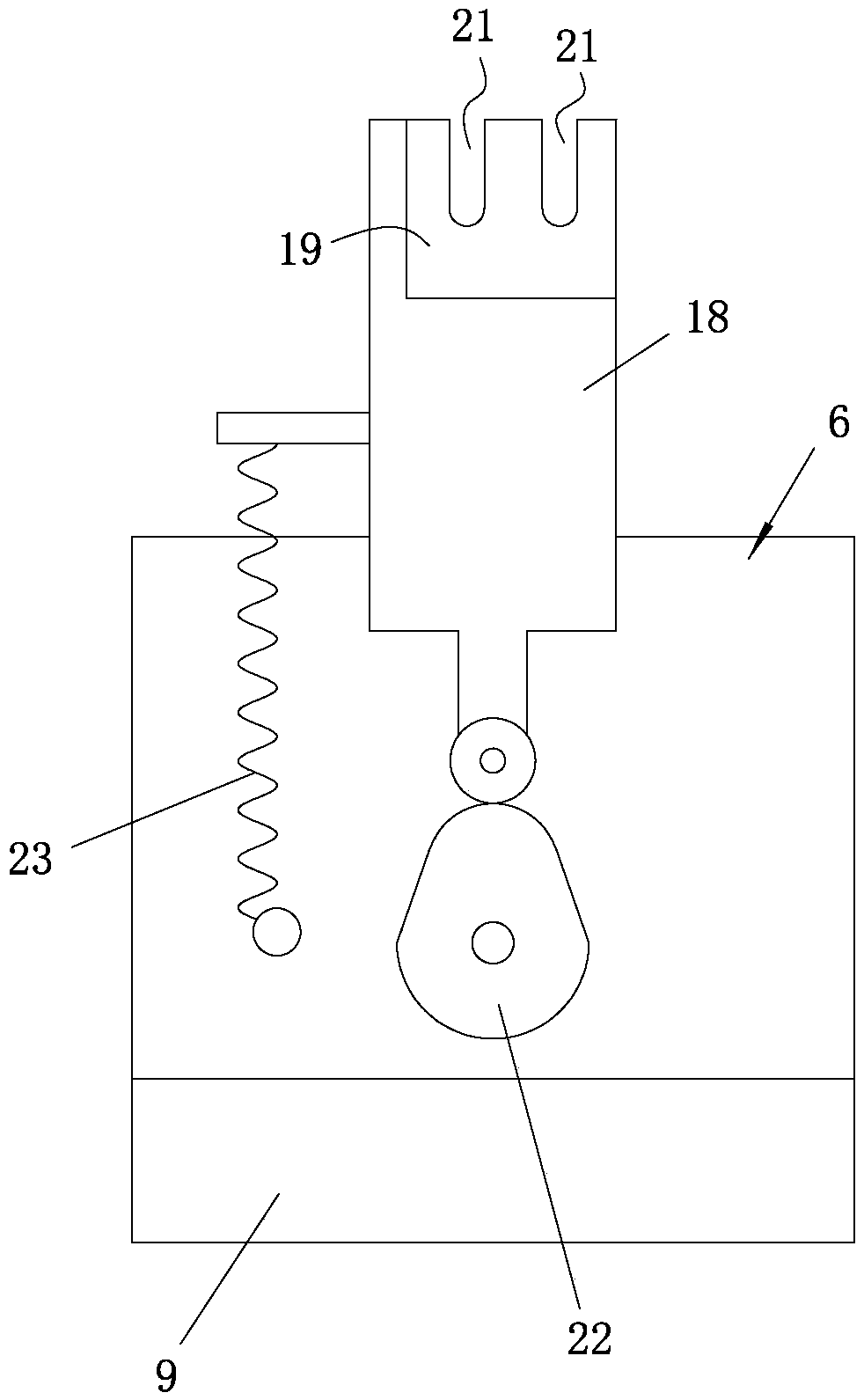

[0031] The transfer mechanism 3 includes a jacking assembly 6 installed on the machine platform 1, a pusher assembly 7, an electronic counter 8 used in conjunction with the jacking asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com