Brush roller for textile printing and dyeing machinery

A technology of textile printing and dyeing, brush roller, applied in the processing of textile materials, textile processing machine accessories, printing and other directions, can solve the problems of inconvenient cleaning, inconvenient disassembly and replacement, etc., and achieve the effect of convenient cleaning and replacement, and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

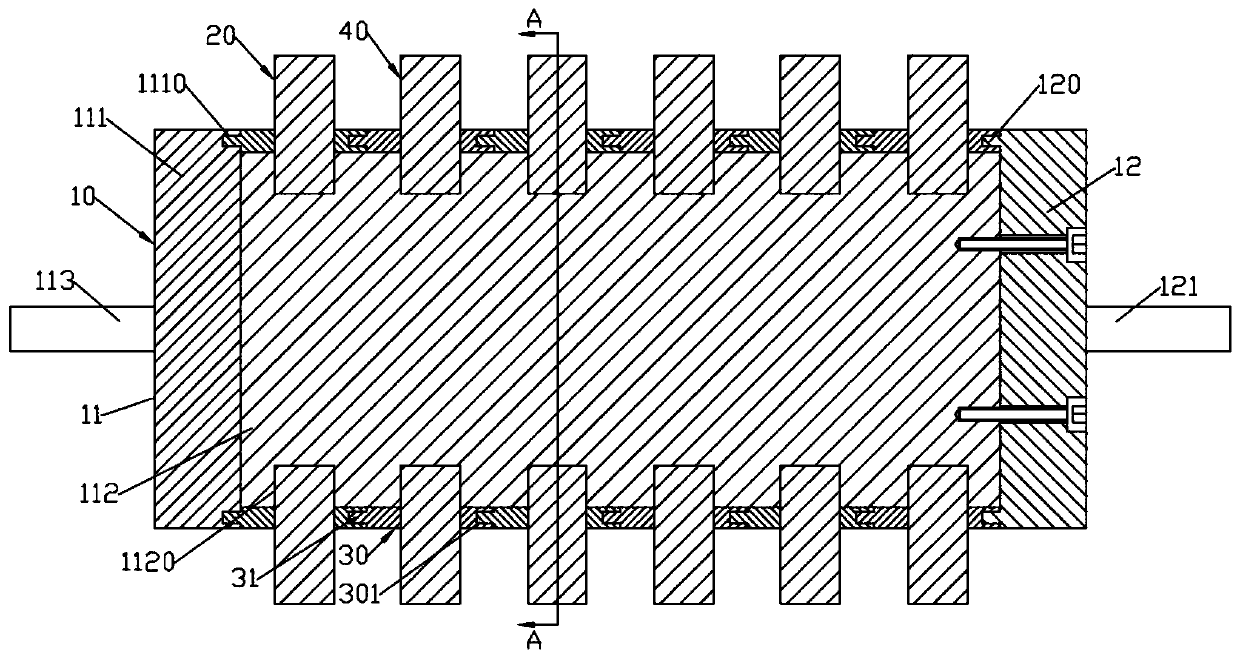

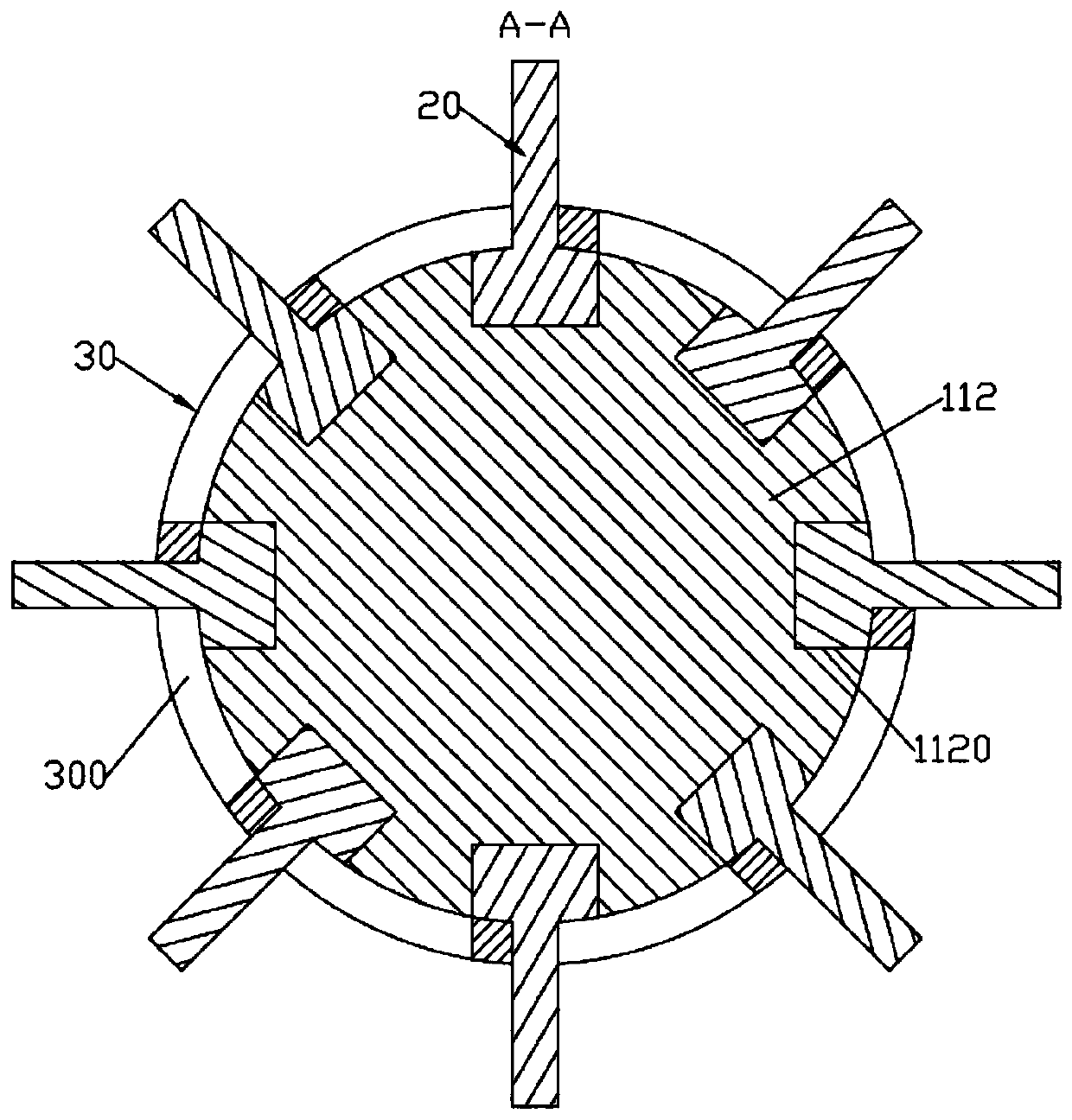

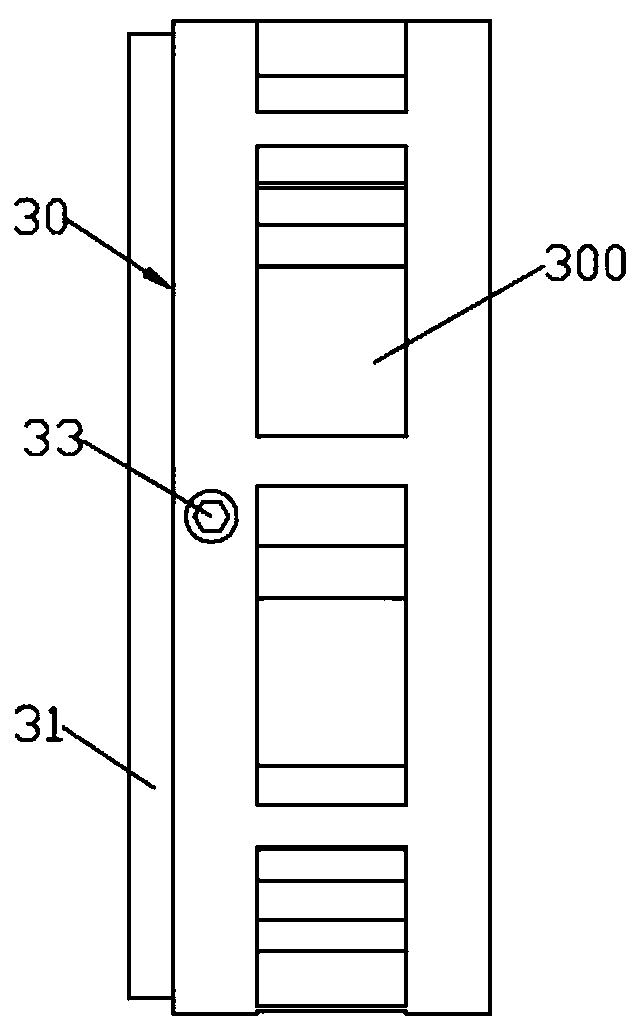

[0015] like Figure 1 ~ Figure 3 As shown, a brush roller for textile printing and dyeing machinery includes a central cylinder 10, a number of first bristle blocks 20, a number of annular cylinder-shaped stop rings 30 evenly distributed on the left and right, and a number of second bristle blocks 40; The central cylinder 10 includes a left central cylinder 11 and a right limit post 12; the left central cylinder 11 consists of a left limit post 111 and a center post 112 formed at the center of the right end face of the left limit post 111; 30 sets of stop rings Set and pivotally connected to the center column 112; the right limit column 12 is fixed on the right end surface of the center column 112 by several bolts; the center of the left end surface of the left limit column 111 is formed with a left metal column 113; the right limit column 12 A right metal column 121 is formed in the center of the right end face; a number of evenly distributed bristle block placement groove gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com