Screen printing machine with inner supporting rotary disc

A technology of screen printing machine and turntable, which is applied to rotary printing machine, screen printing machine, printing machine and other directions, can solve the problems of poor structural design rationality, small production output, low work efficiency, etc., and achieves high degree of equipment automation and production output. Large, high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

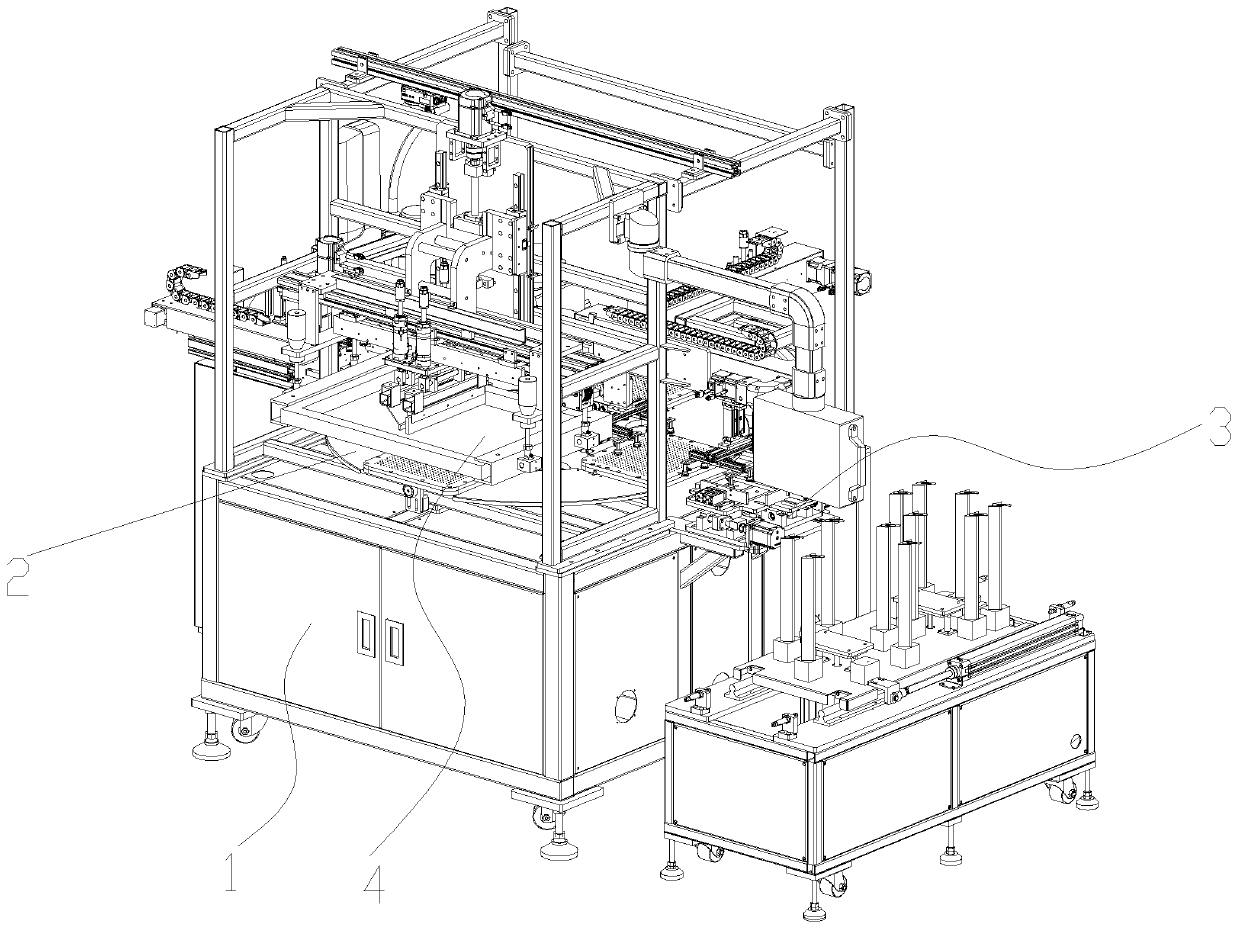

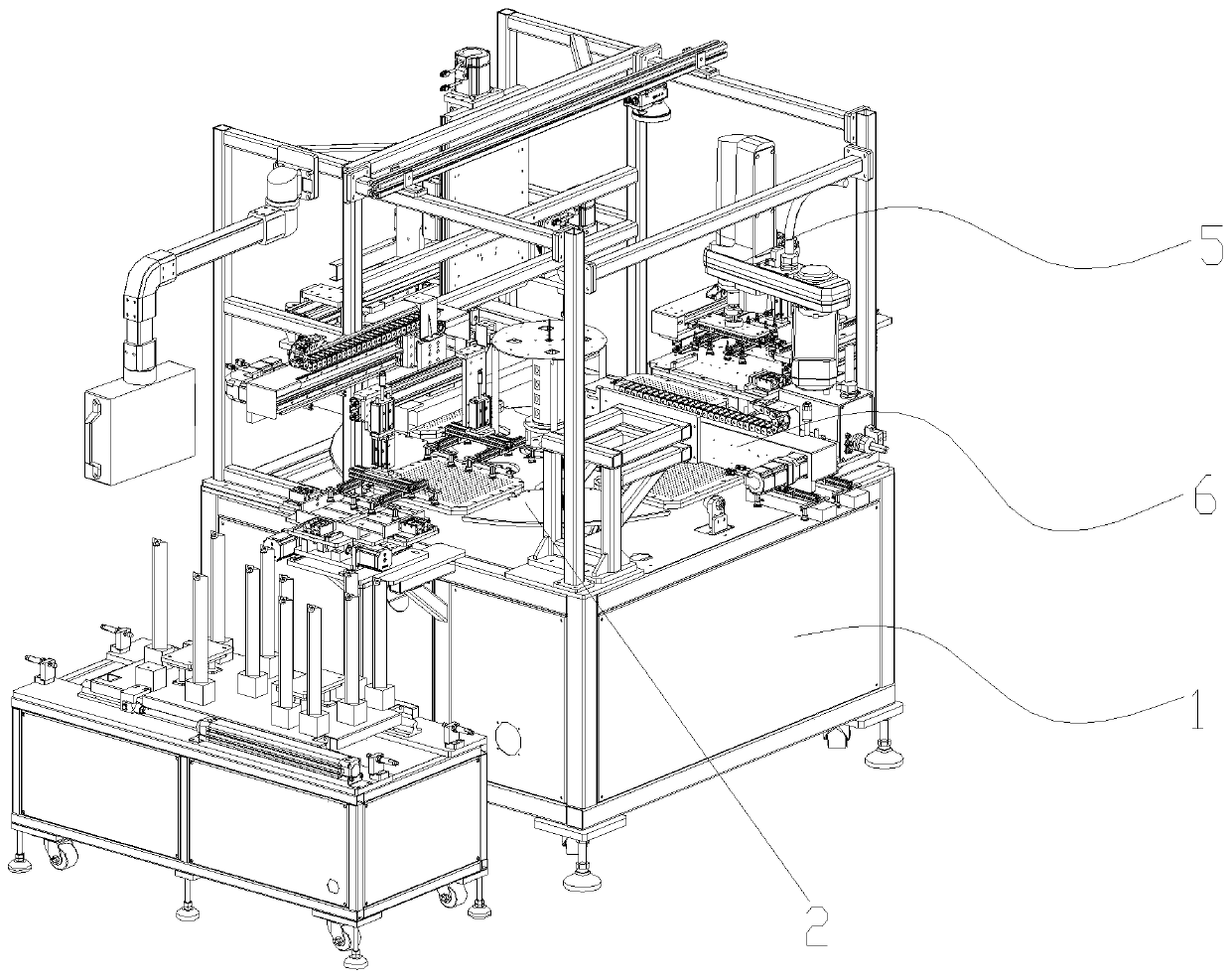

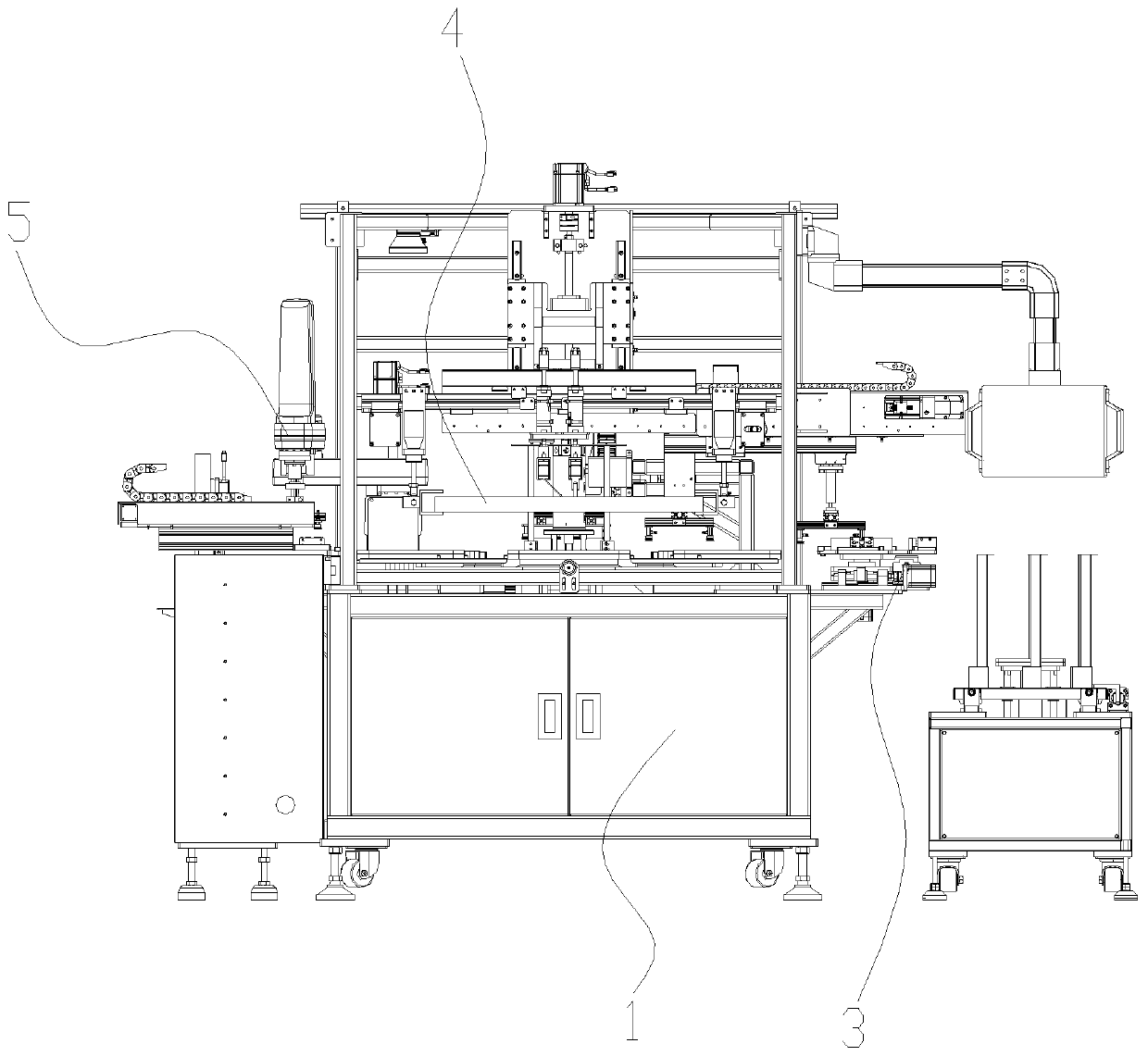

[0069] Such as Figure 1-4 As shown, an inner rotary table screen printing machine is used for the production of packaging boxes, which can realize the pattern printing on the surface of the cardboard and the combination of the cardboard and the gray board. Its structure includes a frame 1 and a turntable installed on the frame 1. 2. The first feeding and positioning mechanism 3 , the silk screen printing mechanism 4 , the second feeding and positioning mechanism 5 and the discharging mechanism 6 are arranged in sequence around the turntable 2 .

[0070] Such as Figure 5 As shown, the frame 1 includes a workbench 11 and a bracket 12 arranged above the workbench 11. An operation panel 13 for controlling the operation of the screen printing machine with the inner support turntable 2 is installed on the side of the support 12; the turntable 2 is arranged abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com