Jacking positioning device for segmented iron outfitting pieces of steam rolled ship deck and using method

A technology of jacking and positioning and iron outfitting, which is applied in the direction of lifting devices, workpiece clamping devices, auxiliary devices, etc., can solve the problems of reducing the quality of ship construction, increasing paint damage, and strengthening the alignment, so as to improve the pre-assembly rate, improve reliability, and avoid the effects of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

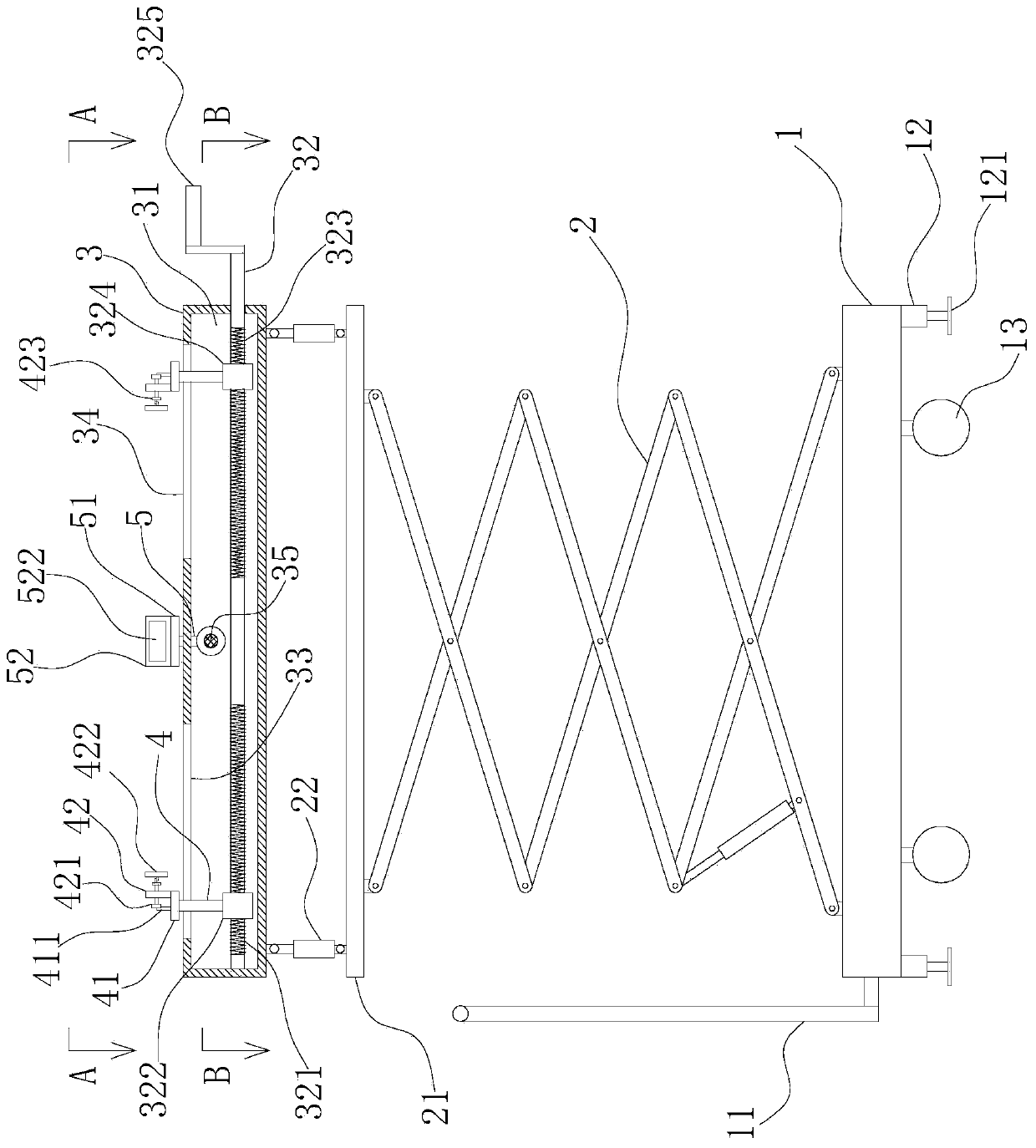

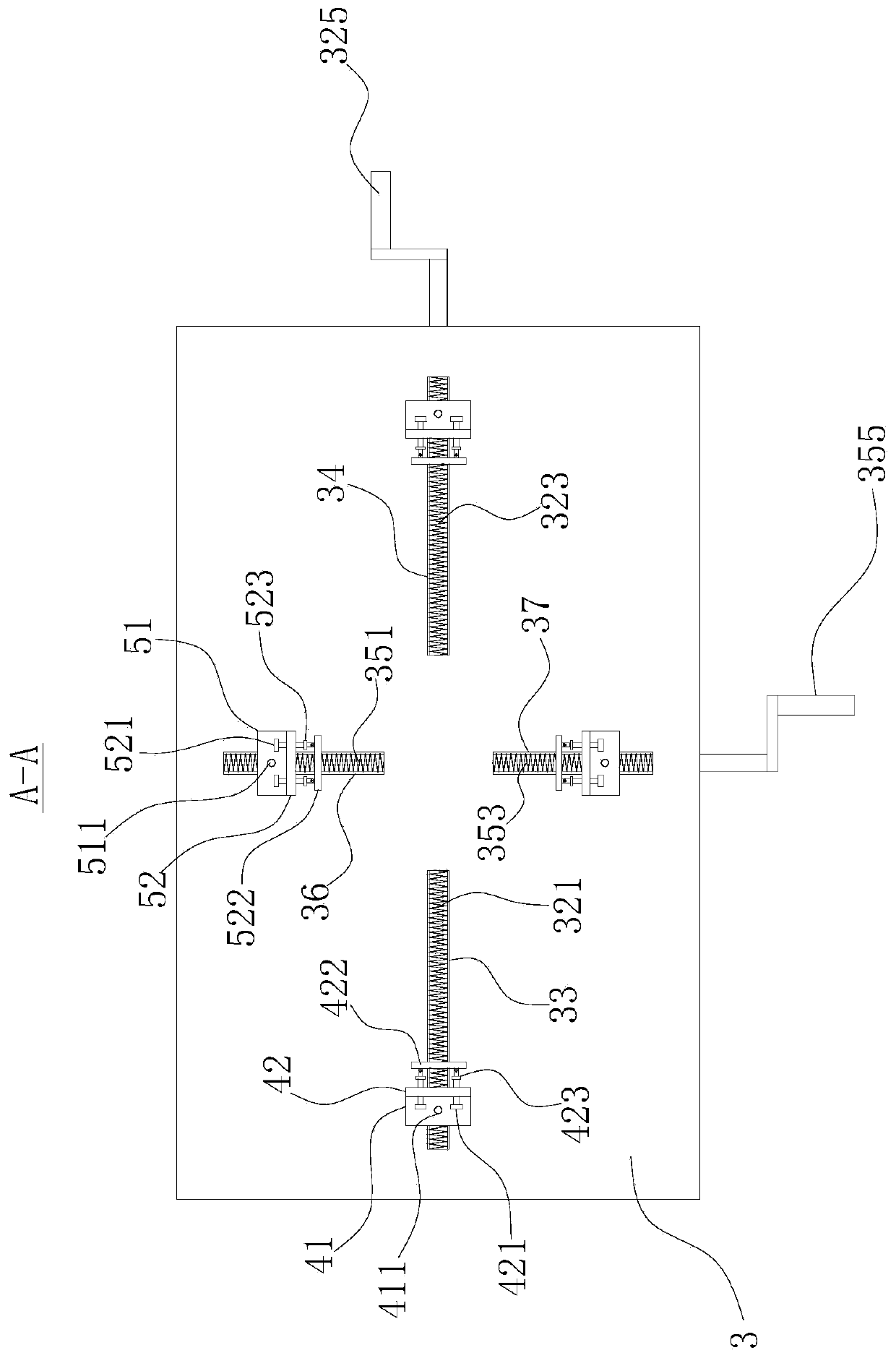

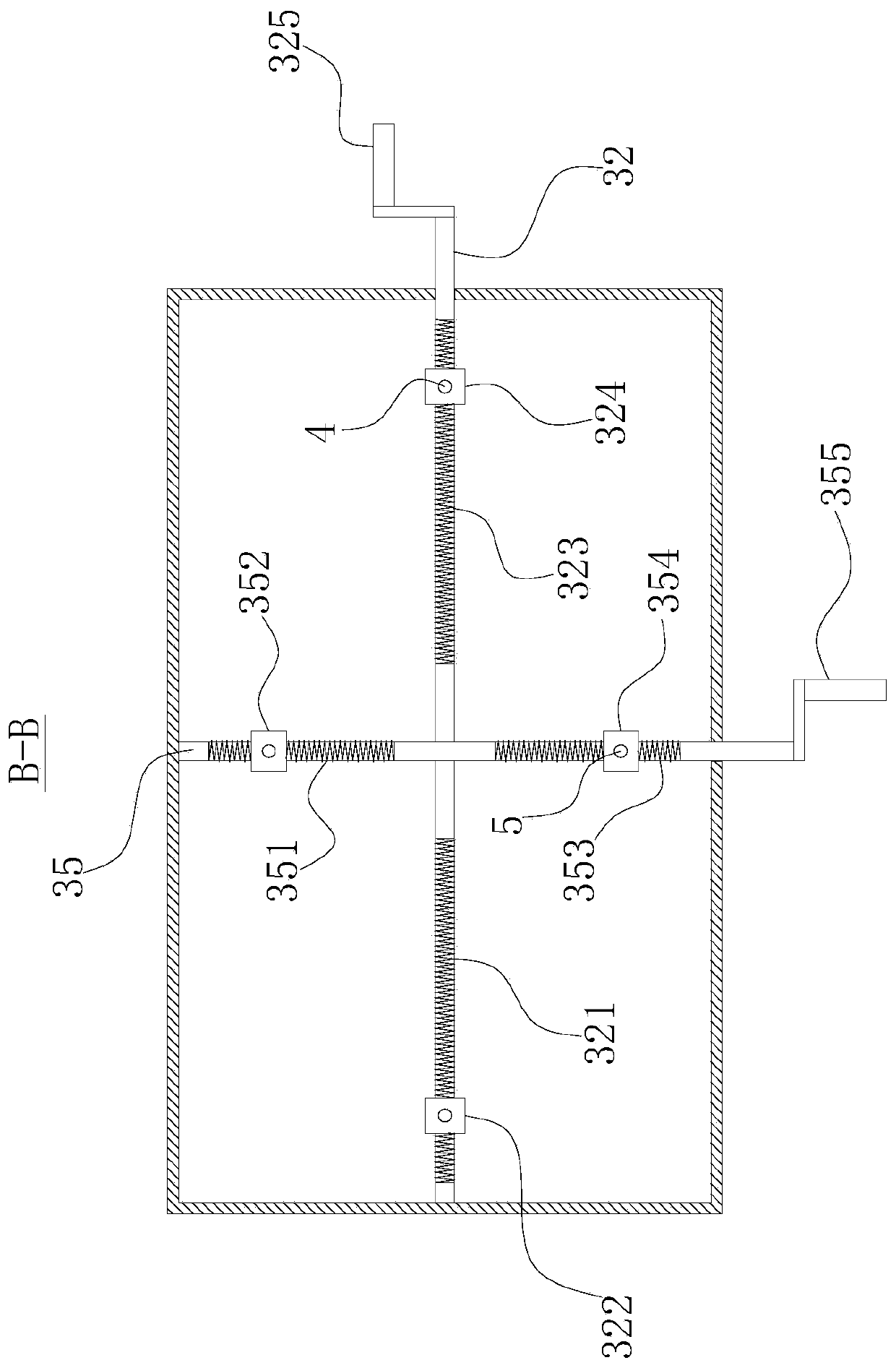

[0054] Such as Figure 1 to 3 As shown, a lifting positioning device for the iron outfitting of the steam rolling ship deck section includes a bottom plate 1, a connecting plate 21, a top block 3, a first screw 32, a second screw 35, a first fixing mechanism and a second Fixed mechanism.

[0055] A number of universal rollers 13 are provided on the lower side of the bottom plate 1, and a hydraulic lifting platform 2 is provided on the upper side of the bottom plate 1.

[0056] The connecting plate 21 is arranged on the upper end of the bottom plate 1 through a hydraulic lifting platform 2.

[0057] The top block 3 is arranged above the connecting plate 21 by an adjusting mechanism, which can adjust the angle between the top block 3 and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com