Pipe gallery module deck hoisting method

A hoisting method and deck technology, used in transportation and packaging, load hoisting components, trolley cranes, etc., can solve the problems of many hoisting times, difficult overall hoisting, long hoisting cycle, etc., to achieve good synchronization and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

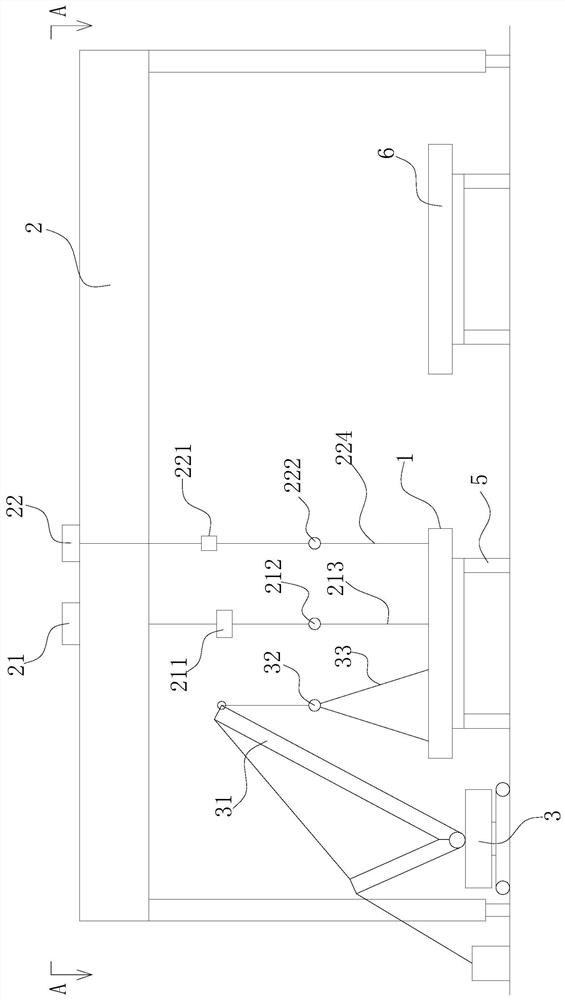

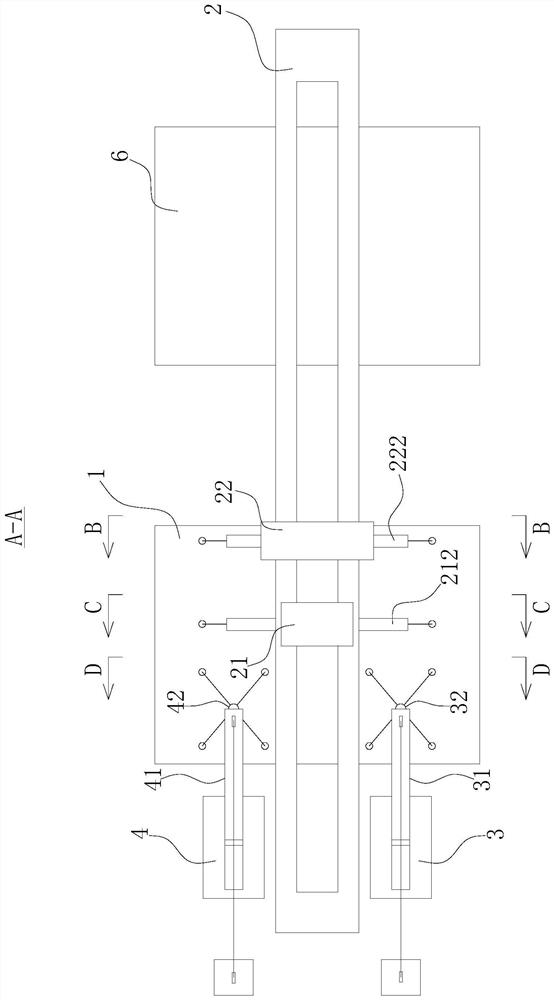

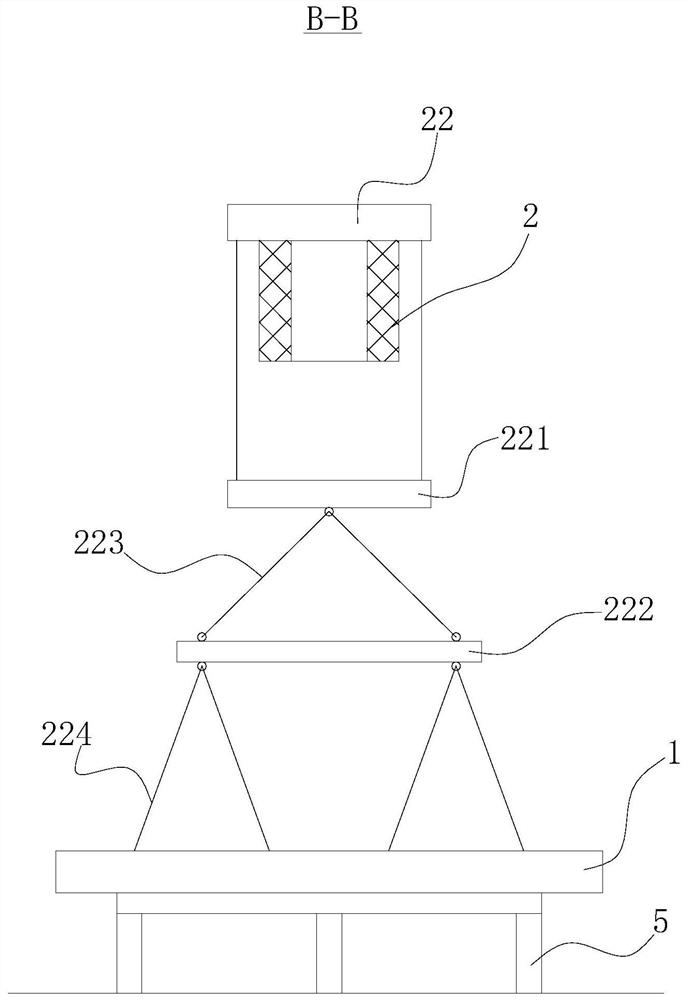

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0035] Such as Figures 1 to 6 As shown, a method for hoisting a pipe gallery module deck, the overall size of the pipe gallery module deck 1 is 62000mm long x 42000mm wide x 14800mm high, and the first crawler vehicle 3 of XGC800, the second crawler vehicle 4 of XGC800 and the gantry crane 2 of 800T are selected Carry out hoisting work.

[0036] The maximum lifting capacity of the first crawler vehicle 3 and the second crawler vehicle 4 are both 325t and have the same model specifications, and the lifting capacities of the lower crane 21 and the upper crane 22 on the gantry crane 2 are 640t and 450t respectively.

[0037] The lifting method includes the following steps:

[0038]S1. Calculate the weight and the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com