A kind of M50 base bearing self-lubricating material and preparation method thereof

A technology of self-lubricating materials and base bearings, applied in shafts and bearings, bearing components, metal material coating technology, etc., can solve the difficulties in adjusting the tribological properties of self-lubricating materials, and the difficulty in reconciling the self-lubricating properties and mechanical properties of self-lubricating materials and other problems, to achieve the effect of simple and novel preparation method, cheap material and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

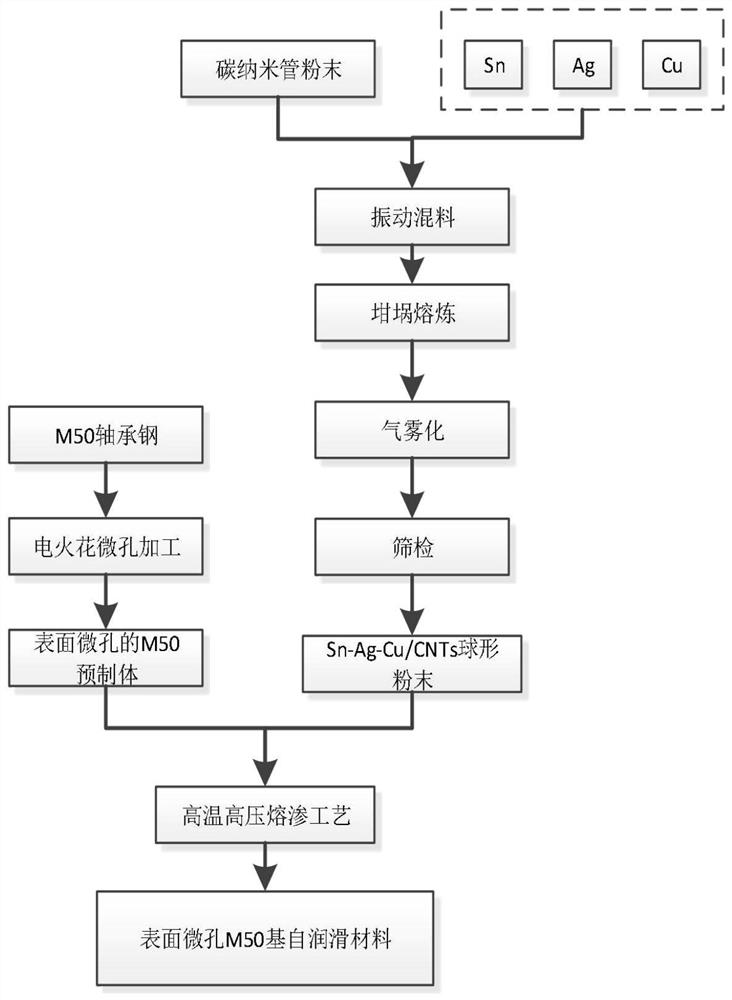

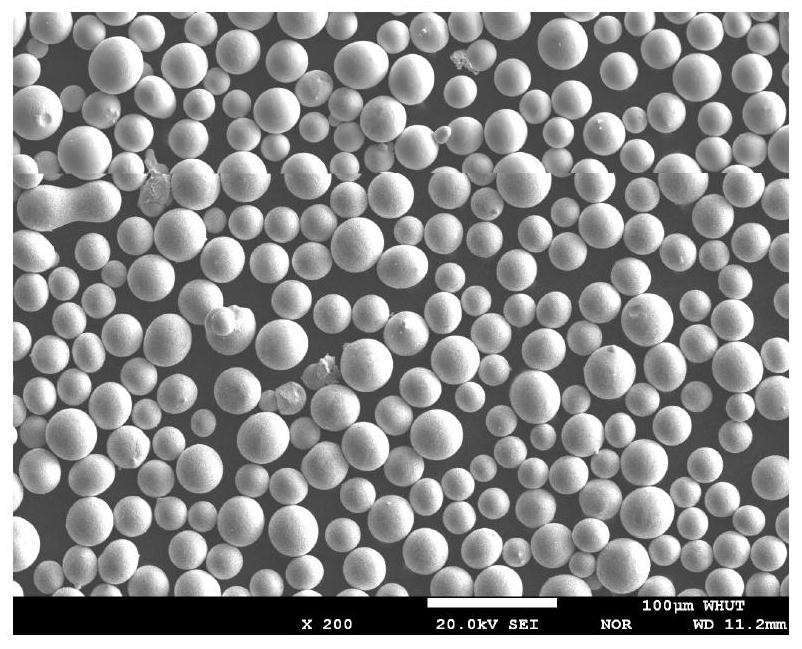

[0032] In the following examples, the M50-based bearing self-lubricating material uses M50 steel as the base material, Sn-Ag-Cu as the lubricating phase, and carbon nanotubes (CNTs) as the reinforcing phase. The technology is to process the micropores on the surface of the M50 bearing steel material, prepare the Sn-Ag-Cu spherical powder containing CNTs by the vacuum atomization method, and then fill the Sn-Ag-Cu / CNTs spherical powder on the surface by the high temperature and high pressure infiltration technology. In the micropore, the M50 base bearing self-lubricating material is obtained. The present invention provides a specific preparation method, but the preparation method is not limited. Sn-Ag-Cu / CNTs spherical powder, surface microporous structure, and M50-based bearing self-lubricating materials prepared by other methods meet the requirements of the present invention. protection scope of the present invention.

[0033] The invention provides a preparation method of M...

Embodiment 1

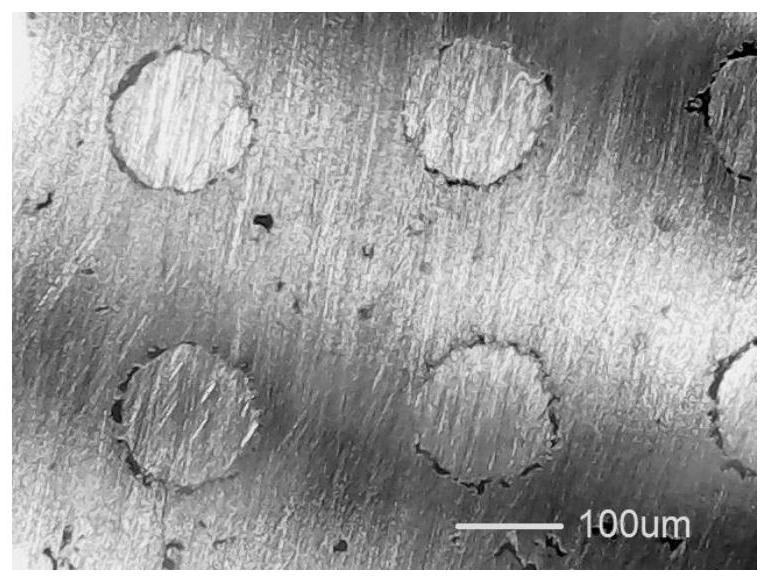

[0039] like figure 1 As shown in the figure, a preparation method of M50-based bearing self-lubricating material is to use EDM micro-hole machining technology to process micro-holes on the surface of M50 bearing steel material, and secondly, use vacuum atomization to prepare Sn-Ag-Cu / CNTs spherical powder, and then use the high temperature and high pressure infiltration technology to fill the Sn-Ag-Cu / CNTs spherical powder in the surface micropores to obtain an M50-based bearing self-lubricating material. Specific steps are as follows:

[0040] 1) M50 bearing steel material is selected, and the surface of M50 is micro-processed by EDM micro-hole machining technology. The diameter of the micro-hole is 200 μm, the depth of the micro-hole is 800 μm, and the distance between two adjacent micro-holes is equal, which is 700 μm;

[0041] The process parameters of EDM micro-hole machining are pulse width of 600nS and pulse-to-pulse range of 400nS;

[0042] 2) Select Sn, Ag, Cu, and...

Embodiment 2

[0047] A preparation method of M50-based bearing self-lubricating material, which is to use EDM micro-hole machining technology to process array micro-holes on the surface of M50 bearing steel material, and secondly, use vacuum atomization method to prepare Sn-Ag-Cu / CNTs spherical shape powder, and then use the high temperature and high pressure infiltration technology to fill the Sn-Ag-Cu / CNTs spherical powder in the surface micropores to obtain the M50-based bearing self-lubricating material. Specific steps are as follows:

[0048] 1) Select M50 bearing steel material, and use EDM micro-hole machining technology to micro-hole process the M50 surface. The diameter of the micro-hole is 250 μm, the depth of the micro-hole is 900 μm, and the distance between two adjacent micro-holes is equal, which is 850 μm;

[0049] The process parameters of EDM micro-hole machining are pulse width of 750nS and pulse-to-pulse range of 550nS;

[0050] 2) Select Sn, Ag, Cu, CNTs powder, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com