Reinforced polyvinyl fluoride composite film and preparation method thereof

A technology of polyvinyl fluoride and composite film, applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., to achieve the effects of wide application range, excellent weather resistance, and high strength of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

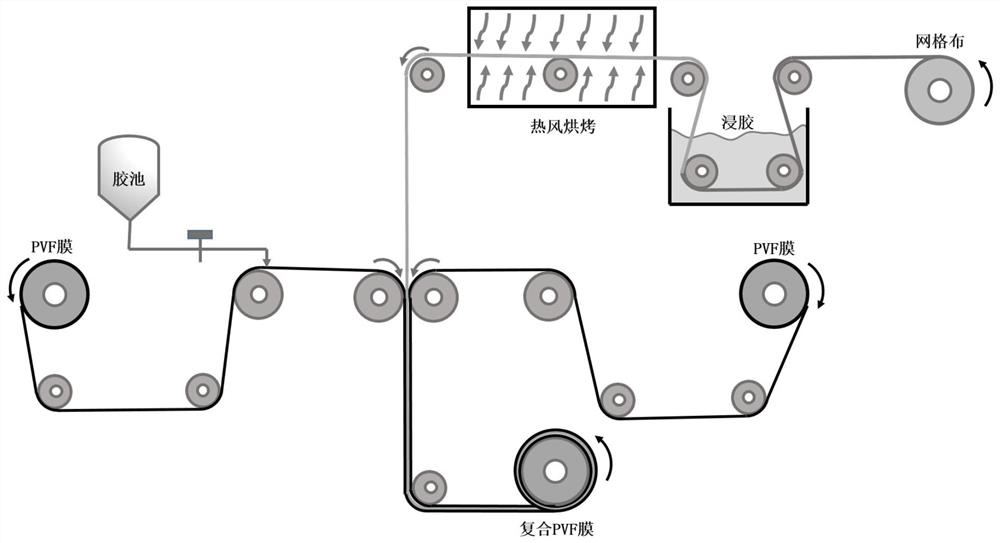

Method used

Image

Examples

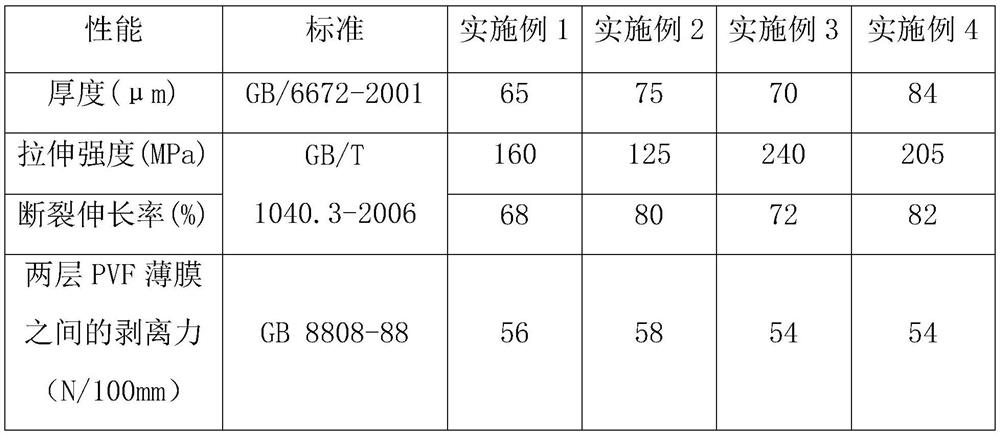

Embodiment 1

[0034] A reinforced polyvinyl fluoride composite film, using a steel belt as a carrier, disperses 100 parts of polyvinyl fluoride resin in 200 parts of γ-butyrolactone at high speed, and the prepared polyvinyl fluoride resin dispersion is extruded by twin-screw Machine, filter, melt metering pump, casting mold, casting on the steel belt, after devolatilization (release latent solvent) and stripping, a PVF casting film with a thickness of 15 μm is obtained, and the surface tension is 36 dynes. The PVF cast film is subjected to corona treatment to obtain the PVF cast film. The obtained PVF casting film has a thickness of 15 μm, a surface tension of 45 dynes, a tensile strength of 30.7 MPa, and an elongation at break of 187.4%.

[0035] Melt the SIS hot melt adhesive in advance, and apply a layer of 8μm hot melt adhesive on the PVF film through the casting mold, and then coat it with nylon mesh cloth (1# mesh cloth) and another layer of hot melt adhesive The PVF film is hot-comp...

Embodiment 2

[0037] A reinforced polyvinyl fluoride composite film, using a steel belt as a carrier, disperses 100 parts of polyvinyl fluoride resin in 160 parts of γ-butyrolactone at high speed, and the prepared polyvinyl fluoride resin dispersion is pre-extruded by a single screw Extrude the machine for granulation, then pass through the twin-screw extruder, filter, melt metering pump, and casting die, and then cast on the steel belt. After devolatilization (removal of latent solvent) and stripping, a 20μm thick PVF casting is obtained. The film has a surface tension of 36 dynes, and the PVF cast film is further subjected to corona treatment to obtain a PVF cast film. The prepared PVF casting film had a thickness of 20 μm, a surface tension of 50 dynes, a tensile strength of 38.5 MPa, and an elongation at break of 170.2%.

[0038] Melt the polyurethane hot melt adhesive in advance, and apply a layer of 10μm hot melt adhesive on the PVF film through a casting mold, and then coat it with n...

Embodiment 3

[0040] A reinforced polyvinyl fluoride composite film, which is prepared by dispersing 100 parts of polyvinyl fluoride resin in 230 parts of N,N-dimethylformamide (DMF) at a high speed, using PET film coated with silicone oil as a carrier. The polyvinyl fluoride resin dispersion is cast on a PET film coated with silicone oil through a twin-screw extruder, a filter, a melt metering pump, and a casting die, and after devolatilization (removal of latent solvent) and stripping, 10 μm PVF is obtained The casting film is further subjected to corona treatment on the PVF casting film to obtain the PVF casting film. The obtained PVF casting film has a thickness of 10 μm, a surface tension of 55 dynes, a tensile strength of 33.6 MPa, and an elongation at break of 225.8%.

[0041] Melt the polyamide hot melt adhesive in advance, and apply a layer of 15μm hot melt adhesive on the PVF film through a casting mold, and then coat it with nylon mesh cloth (3# mesh cloth) and another layer of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com