A kind of m50-sn-ag-cu microporous channel self-lubricating composite material and its preparation method

A technology of microporous flow channel and composite material, which is applied in the field of M50-Sn-Ag-Cu microporous flow channel self-lubricating composite material and its preparation, can solve the problem that the application of self-lubricating composite material cannot be realized and the uniformity of material structure is affected. , reduce the mechanical properties of materials, etc., to achieve the effects of simple and novel preparation methods, strong industrial promotion value, and improved mechanical properties and friction and wear properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the following examples, the self-lubricating composite material of a M50-Sn-Ag-Cu microporous flow channel uses Sn-Ag-Cu spherical powder and M50 spherical powder as raw materials. According to the designed microporous flow channel The structural parameters are prepared by 3D printing. The present invention provides a specific preparation method, but does not limit its preparation method. The Sn-Ag-Cu spherical powder, M50 spherical powder, microporous flow channel structure, M50-Sn-Ag prepared by other methods meet the requirements of the present invention. -Cu microporous channel self-lubricating composite material also belongs to the protection scope of the present invention.

[0039] The invention provides a preparation method of M50-Sn-Ag-Cu microporous channel self-lubricating composite material, comprising the following steps:

[0040] 1) According to the constituent elements and their contents of the M50 steel, the elemental powder of the constituent element...

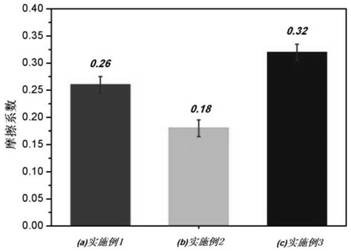

Embodiment 1

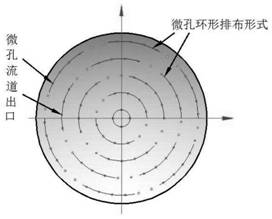

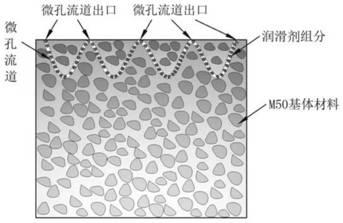

[0046] A M50-Sn-Ag-Cu microporous flow channel self-lubricating composite material, including a matrix material, a lubricating phase and a microporous flow channel structure, which uses M50 steel as the matrix material and Sn-Ag-Cu alloy as the lubricating phase, The microporous flow channel is formed by the arrangement of the lubricating phase, and the microporous flow channel structure is used as the lubricating phase to realize the structural form of lubrication. Wherein, there are several micropore flow channels, and each micropore flow channel adopts a circular arrangement form, and each ring of micropore flow channels forms a ring shape with positive dazzling waves extending axially, and each peak of the sine wave is The outlet of the micropore flow channel is distributed on the grinding surface of the composite material and the outside. Among them, the matrix material M50 steel includes elements C, Mn, Si, Ni, Cr, Cu, Mo, V and Fe, and the mass ratio of elements C, Mn, ...

Embodiment 2

[0057] A M50-Sn-Ag-Cu microporous flow channel self-lubricating composite material, including a matrix material, a lubricating phase and a microporous flow channel structure, which uses M50 steel as the matrix material and Sn-Ag-Cu alloy as the lubricating phase, The microporous flow channel is formed by the arrangement of the lubricating phase, and the microporous flow channel structure is used as the lubricating phase to realize the structural form of lubrication. Wherein, there are several micropore flow channels, and each micropore flow channel adopts a circular arrangement form, and each ring of micropore flow channels forms a ring shape with positive dazzling waves extending axially, and each peak of the sine wave is The outlet of the micropore flow channel is distributed on the grinding surface of the composite material and the outside. Among them, the matrix material M50 steel includes elements C, Mn, Si, Ni, Cr, Cu, Mo, V and Fe, and the mass ratio of elements C, Mn, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com