M50-based bearing self-lubricating material and preparation method thereof

A technology of self-lubricating materials and base bearings, applied in the direction of bearing components, shafts and bearings, metal material coating technology, etc., can solve the difficulties in adjusting the tribological properties of self-lubricating materials, and the difficulty in reconciling the self-lubricating properties and mechanical properties of self-lubricating materials and other problems, to achieve the effect of simple and novel preparation method, good lubricating effect and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

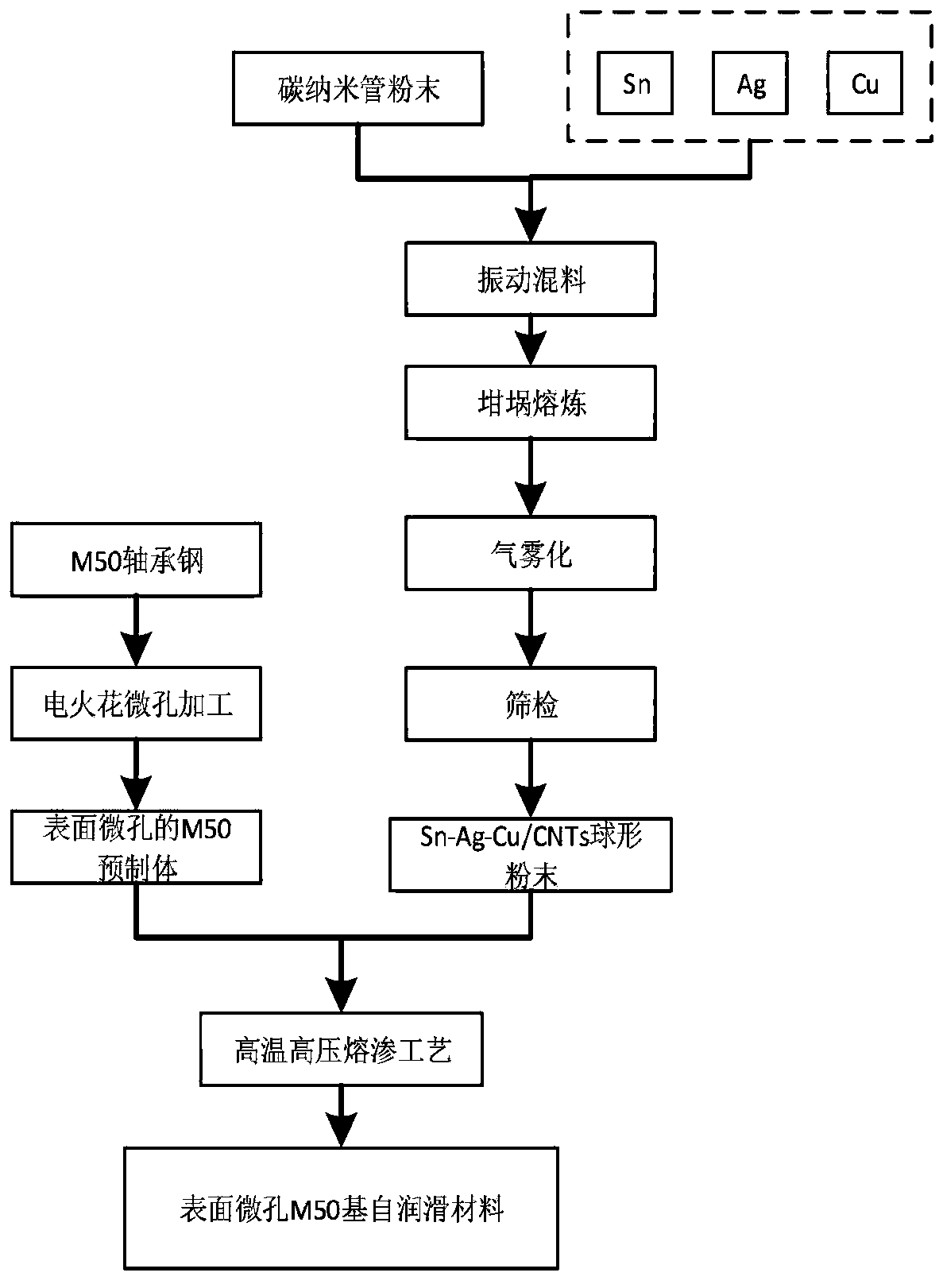

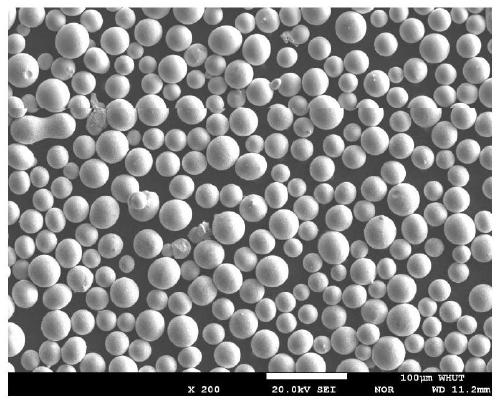

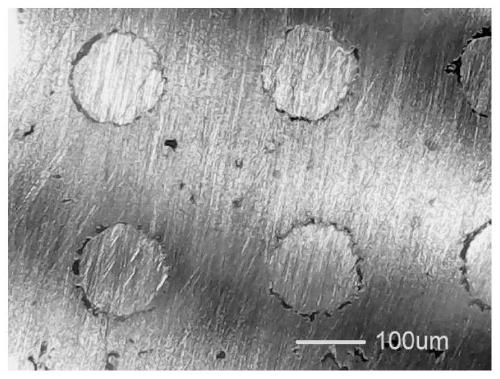

[0032] In the following examples, the M50-based bearing self-lubricating material is based on M50 steel as the base material, with Sn-Ag-Cu as the lubricating phase, and carbon nanotubes (CNTs) as the reinforcing phase, using EDM microporous machining Micropores are arranged in an array on the surface of M50 bearing steel material, and Sn-Ag-Cu spherical powder containing CNTs is prepared by vacuum atomization method, and then Sn-Ag-Cu / CNTs spherical powder is filled on the surface by high temperature and high pressure infiltration technology In micropores, M50-based bearing self-lubricating materials are obtained. The present invention provides a specific preparation method, but does not limit its preparation method. Sn-Ag-Cu / CNTs spherical powder, surface microporous structure, and M50-based bearing self-lubricating materials prepared by other methods that meet the requirements of the present invention also belong to protection scope of the present invention.

[0033] The i...

Embodiment 1

[0039] Such as figure 1 As shown, a preparation method of M50-based bearing self-lubricating material, it uses EDM microporous machining technology to process and arrange micropores on the surface of M50 bearing steel material, and secondly, prepares Sn-Ag-Cu by vacuum atomization method / CNTs spherical powder, and then use the high temperature and high pressure infiltration technology to fill the Sn-Ag-Cu / CNTs spherical powder in the surface micropores to obtain a M50-based bearing self-lubricating material. Specific steps are as follows:

[0040] 1) Select M50 bearing steel material, and use EDM micro-hole machining technology to process micro-holes on the surface of M50. The diameter of the micro-holes is 200 μm, the depth of the micro-holes is 800 μm, and the distance between two adjacent micro-holes is equal, which is 700 μm;

[0041] The process parameters of EDM micro-hole machining are pulse width 600nS and pulse-to-pulse range 400nS;

[0042] 2) Select Sn, Ag, Cu, a...

Embodiment 2

[0047] A preparation method of M50-based bearing self-lubricating material, which is to use electric spark micro-hole machining technology to process and arrange micro-holes on the surface of M50 bearing steel material, and secondly, prepare Sn-Ag-Cu / CNTs spherical shape by vacuum atomization method powder, and then use the high temperature and high pressure infiltration technology to fill the Sn-Ag-Cu / CNTs spherical powder in the surface micropores to obtain the M50-based bearing self-lubricating material. Specific steps are as follows:

[0048] 1) Select M50 bearing steel material, and use EDM micro-hole machining technology to process micro-holes on the surface of M50. The diameter of the micro-holes is 250 μm, the depth of the micro-holes is 900 μm, and the distance between two adjacent micro-holes is equal, which is 850 μm;

[0049] The process parameters of EDM microhole machining are pulse width 750nS and pulse-to-pulse range 550nS;

[0050] 2) Select Sn, Ag, Cu, and C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com