Anti-floating engineering pile vertical load test detection device and method

A technology of vertical load and detection device, which is used in infrastructure engineering, infrastructure testing, construction, etc., can solve problems such as distortion of test data, deviation of beam lift from the vertical direction, subsidence, etc., and achieve accurate measurement data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

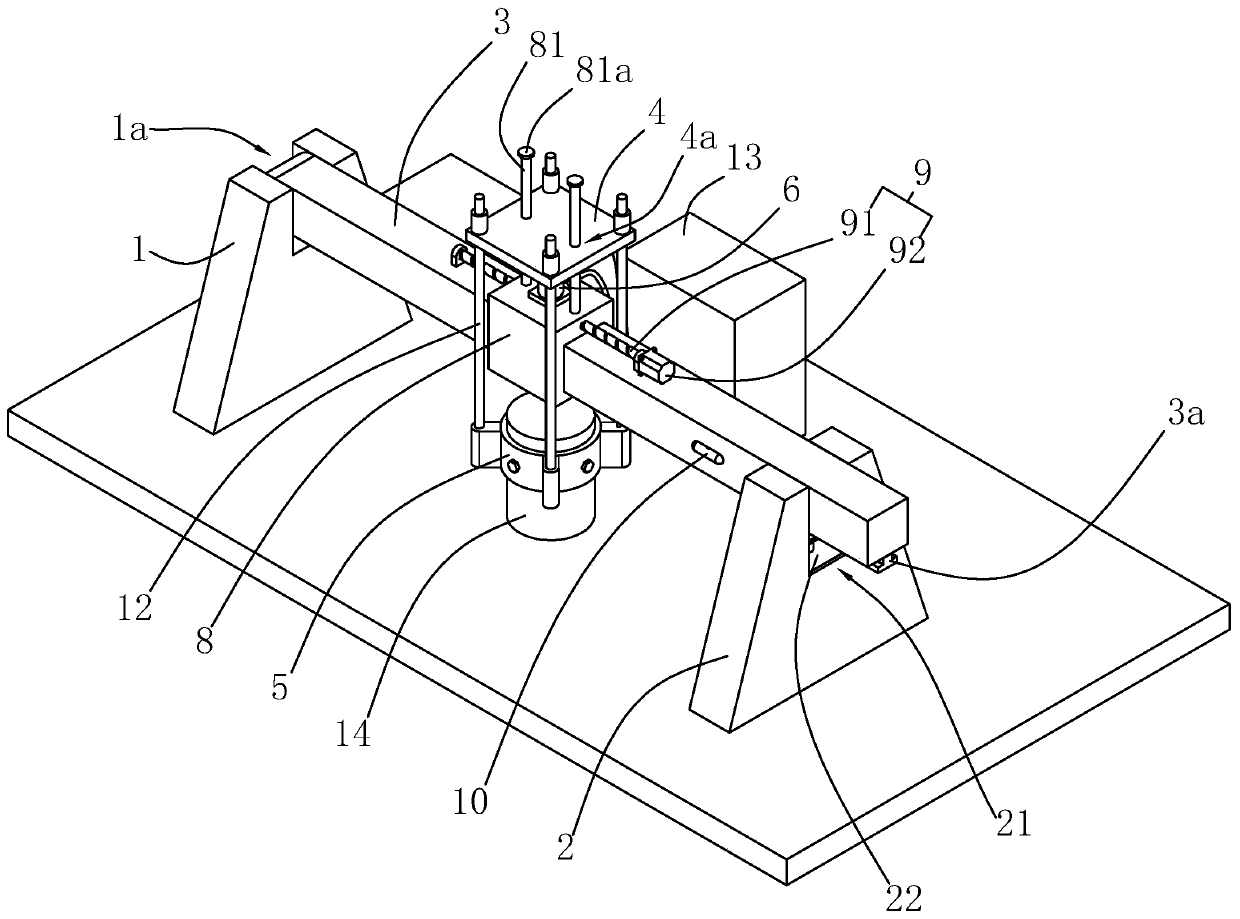

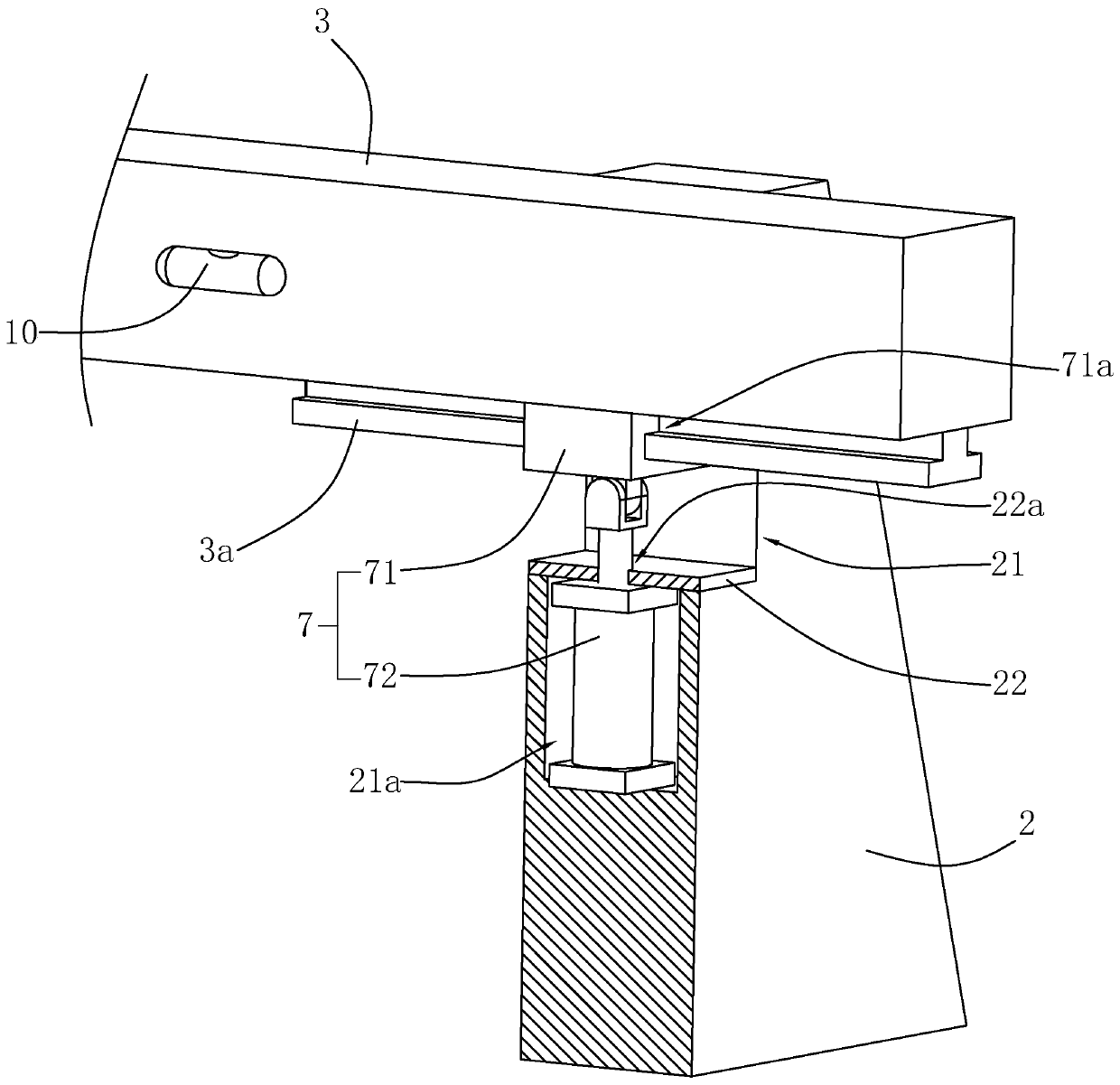

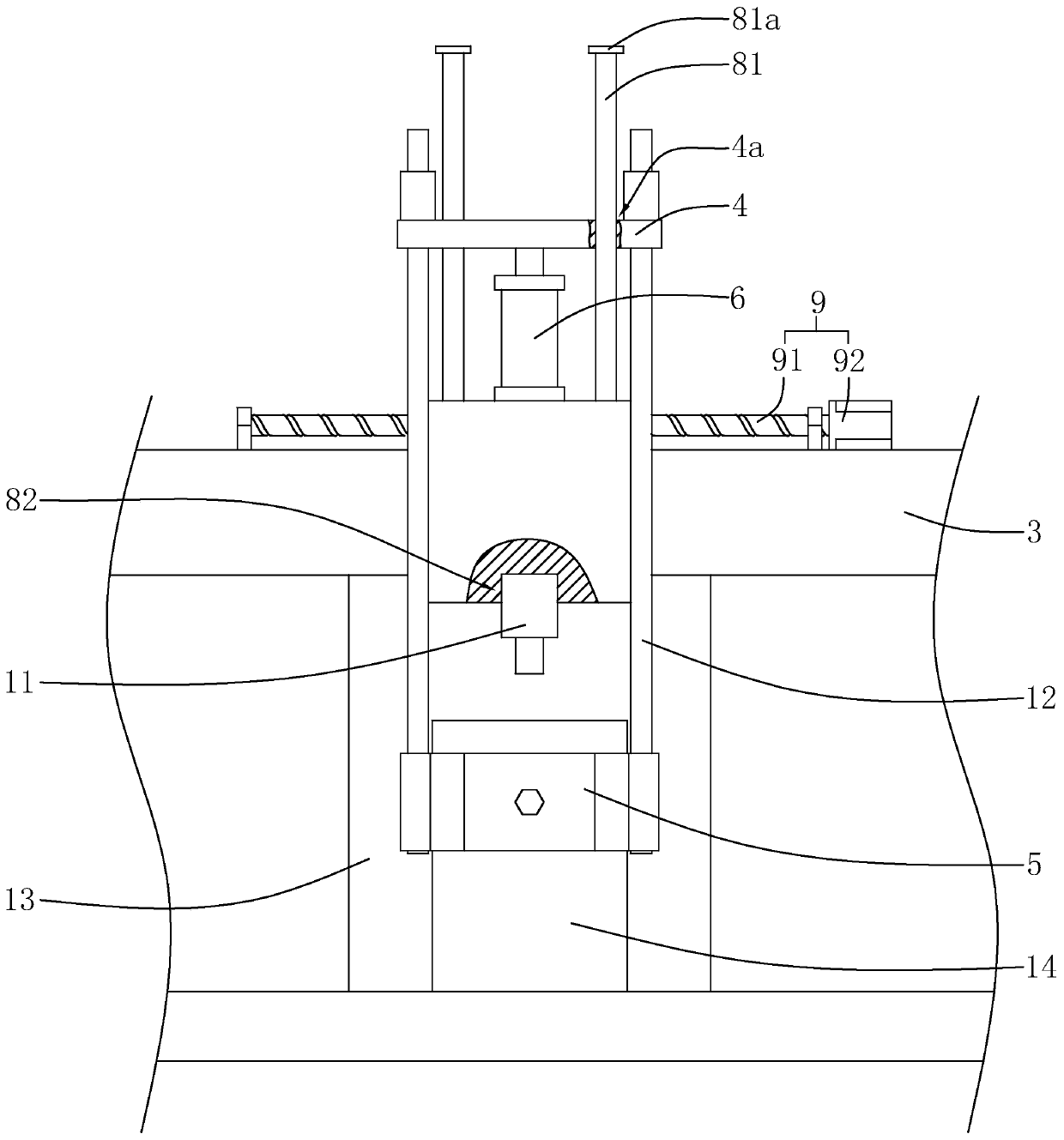

[0040] refer to figure 1 , is an anti-floating engineering pile vertical load test detection device disclosed in the present invention, comprising a first support base 1, a second support base 2, a beam 3, a lifting base frame 4, a connecting frame 5 and a jacking mechanism, wherein, The first support base 1 and the second support base 2 are installed symmetrically on the ground on both sides of the anti-floating engineering pile 14 respectively. The lower end surface of the second support base 2 is larger than the lower end surface, increasing the contact area between the first support base 1 and the second support base 2 against the ground. The crossbeam 3 is a strip-shaped steel beam, and the crossbeam 3 is erected between the first support base 1 and the second support base 2 .

[0041] refer to figure 1 and figure 2 , the upper end of the first support base 1 is provided with a hinge groove 1a, one end of the beam 3 is hinged to the first support base 1, and a first d...

Embodiment 2

[0052] A vertical load test and detection method of an anti-floating engineering pile disclosed by the present invention comprises the following steps:

[0053] S1. Install the detection device, and make the lifting frame above the anti-floating engineering pile 14, and use the first driving mechanism 7 to adjust the angle of the crossbeam 3, so that the adjustment crossbeam 3 is in a horizontal state.

[0054] Manually mark the center point on the upper end surface of the anti-floating engineering pile 14, use the second driving mechanism 9 to adjust the position of the lifting base frame 4, make the alignment part below the lifting base frame 4 align with the marking point of the anti-floating engineering pile 14, and The connecting frame 5 is fixedly connected with the upper end of the anti-floating engineering pile 14 , and the connecting frame 5 is connected with the lifting base frame 4 using a steel cable 12 .

[0055] S2. Use the hydraulic jack 6 to apply a vertical ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com