Intelligent drag reduction control system and method for underground carry-scraper

A technology of control system and control method, which is applied to the program control of sequence/logic controller, electrical program control, earth mover/excavator, etc., which can solve the problems of low work efficiency, reduced service life of equipment, failure of buckets, etc. Problems such as shoveling full of materials to achieve the effect of improving work efficiency, improving service life and avoiding hard confrontation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

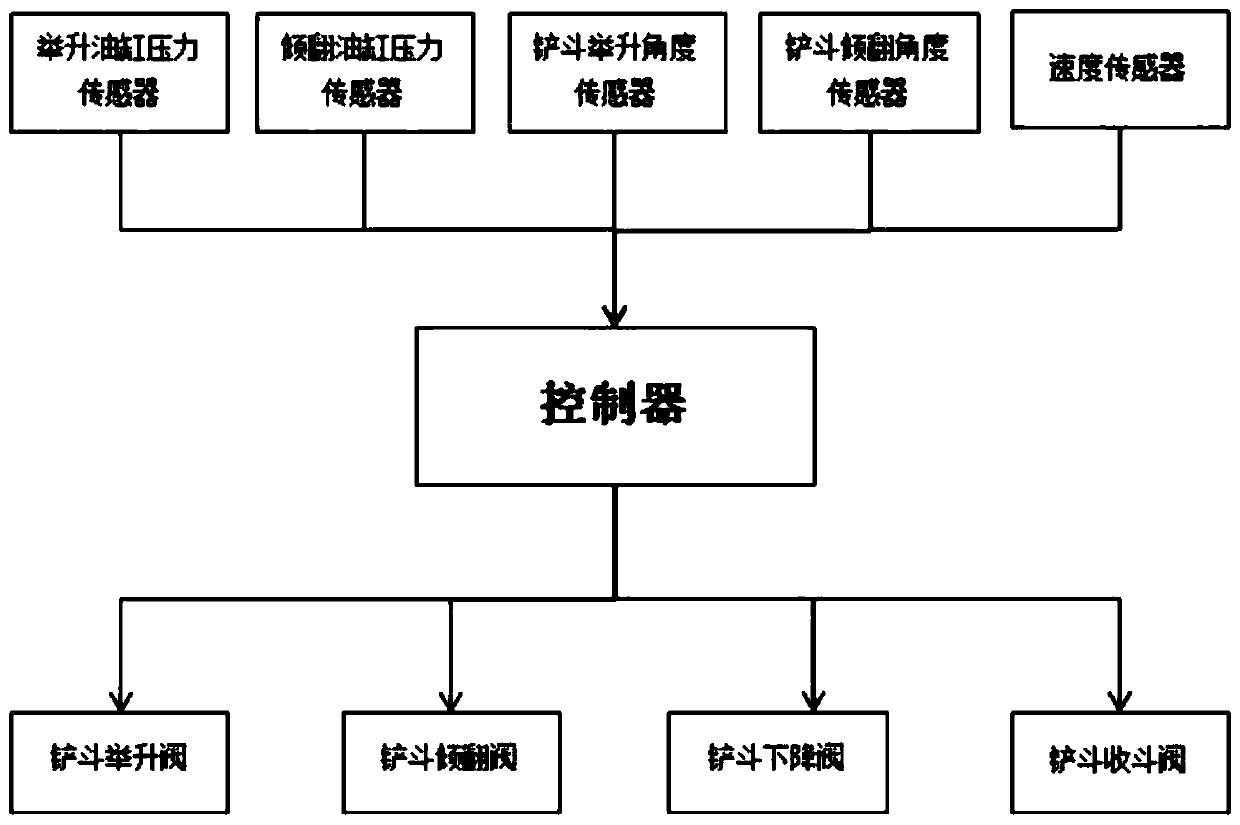

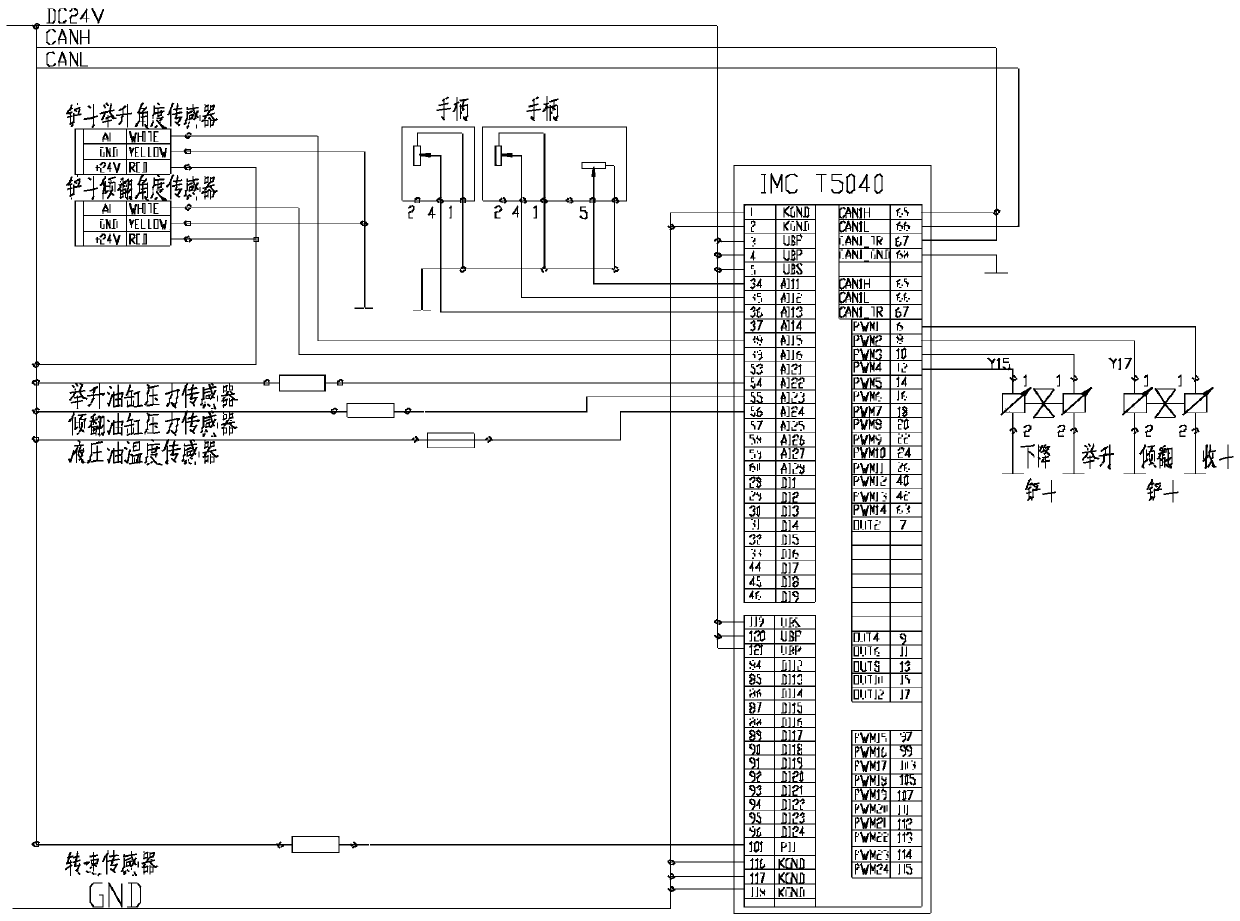

[0021] The underground scraper includes a working device, a power device, and a walking device, among which the working device includes a bucket, a boom, a connecting rod, a rocker arm, a tilting cylinder, and a lifting cylinder. The working process of the underground scraper is mainly reflected in the working device, and its action is composed of five working conditions, insertion working condition, shovel loading working condition, lifting working condition, unloading working condition and automatic leveling working condition. The present invention mainly occurs in the insertion working condition and the shovel loading working condition. Because gangue, large stones, etc. that are heavy or fixedly connected to the ground will be arranged in the stockpiling material, that is, the dense nucleus will hinder the insertion and shoveling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com