Quick inserting component for building external wall insulation board

A technology for building exterior walls and thermal insulation boards, which is applied to building components, building structures, thermal insulation, etc., and can solve problems such as structural instability, slow installation speed, and laborious installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

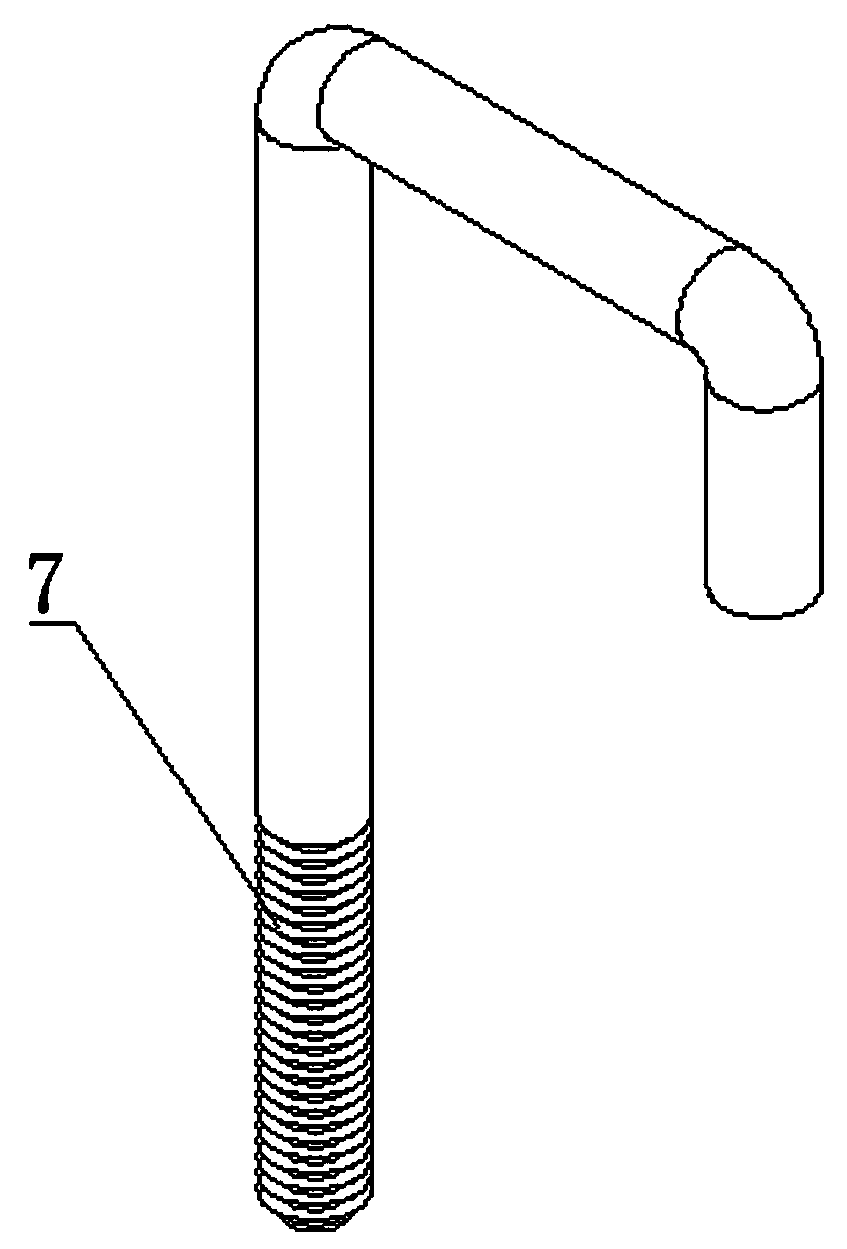

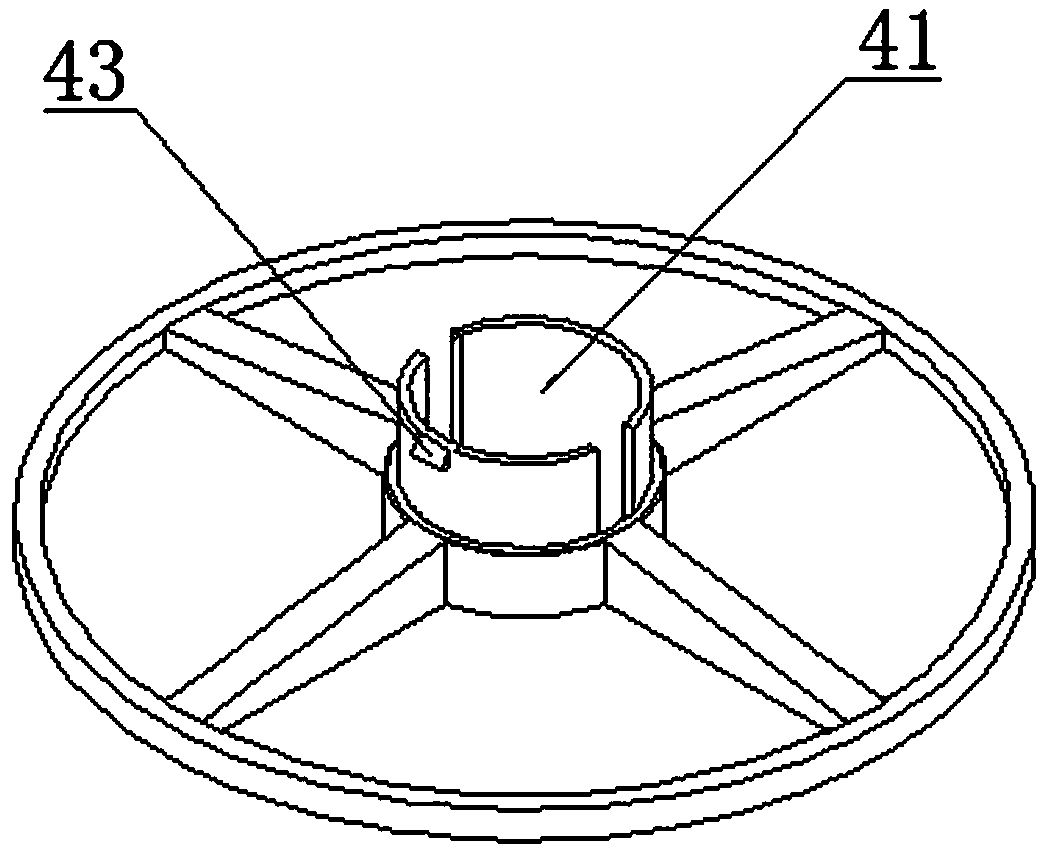

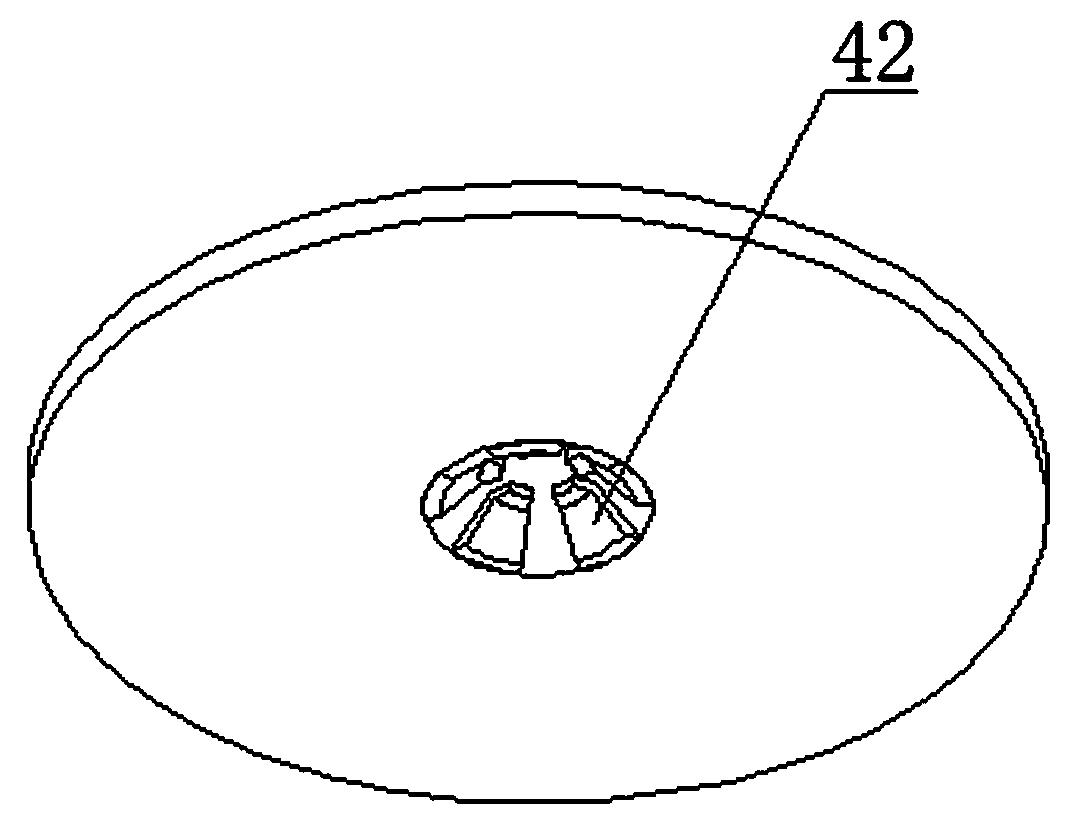

[0034] Such as Figure 1-5 As shown, a quick-insert member for building exterior wall insulation boards includes an outer cushion block 2 placed outside the insulation board 1, an outer grid 3 and an inner connection seat 4 placed inside the insulation board 1. The outer grid, the outer pad, the insulation board, and the inner connecting seat are connected as a whole through a single-rod connecting rod, the side wall of the single-rod connecting rod is provided with an anti-off shoulder 7, and the inner connecting seat 4 is provided with a mounting platform 41. The installation table 41 is a ring wall structure, and the ring wall is provided with five elastic movable flaps 42, which extend toward the center line of the ring wall and the direction of connecting rod insertion. The elastic movable valve in the connecting seat is snapped, when the connecting piece enters, the elastic movable valve can be pushed away and inserted easily. After the connecting piece is inserted, it i...

Embodiment 2

[0037] Such as Figure 5-9 As shown, a quick plug-in component for building exterior wall insulation boards includes outer pads 2 placed outside the insulation board 1, outer grids 3 and inner connection seats 4 placed inside the insulation board 1, and the outer The grid, the outer spacer, the insulation board, and the inner connecting seat are connected as a whole through a single-rod connecting rod, the side wall of the single-rod connecting rod is provided with an anti-off shoulder 7, and the inner connecting seat 4 is provided with a mounting platform 41 , the installation platform is a ring wall structure, such as Figure 6 As shown, a card interface is provided on the circumferential surface of the ring wall, an elastic clip 44 is arranged inside the card interface, and a clip shoulder 43 is arranged on the outer surface of the elastic clip. Such as image 3 As shown, the ring wall is provided with five elastic movable flaps 42, and the elastic movable flaps 42 extend...

Embodiment 3

[0039] Such as Figure 11-15 As shown, a quick plug-in component for building exterior wall insulation boards includes outer pads 2 placed outside the insulation board 1, outer grids 3 and inner connection seats 4 placed inside the insulation board 1, and the outer The grid, the outer spacer, the insulation board, and the inner connecting seat are connected as a whole through a double-rod connecting rod, the side wall of the double-bar connecting rod is provided with an anti-off shoulder 7, and the inner connecting seat 4 is provided with a mounting platform 41 , the installation platform 41 is a ring wall structure, two groups of card interfaces are provided on the circumferential surface of the ring wall, and a group of elastic clips 44 are respectively arranged in the two groups of card interfaces, and the shoulders 43 are arranged on the outer side of the elastic clips. The ring wall is provided with four elastic movable flaps 42, and the elastic movable flaps 42 extend to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com