Bracket for special-shaped wall construction and installation method thereof

A special-shaped and bracket technology, applied in covering/lining, construction, building structure, etc., can solve problems such as affecting wall installation, poor adaptability and poor stability of wall brackets, and reduce safety hazards and installation difficulties. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

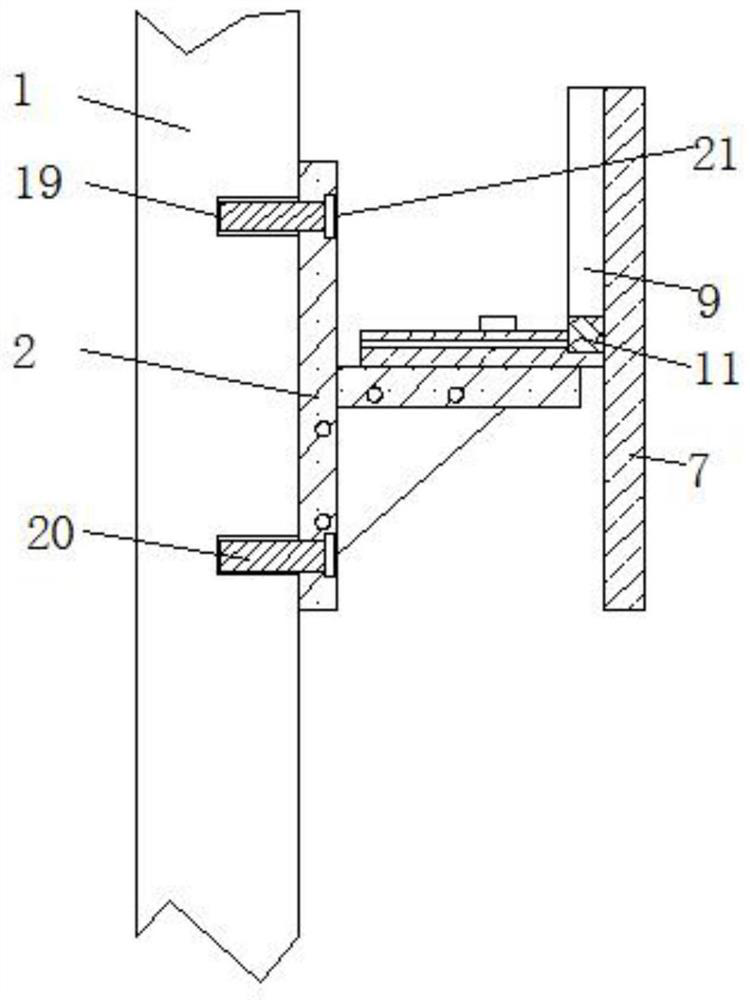

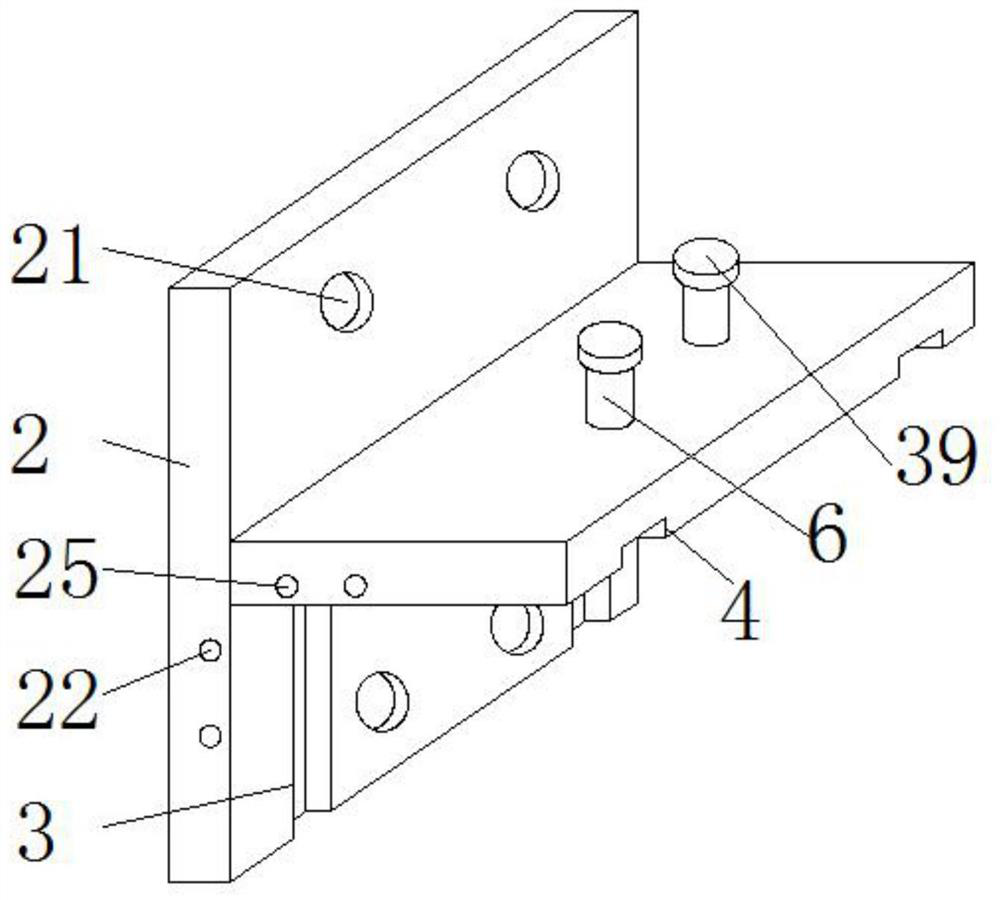

[0045] see Figure 1-10 , according to an embodiment of the present invention, a special-shaped wall construction bracket and its installation method include a wall body 1, and the outside of the wall body 1 is fixedly connected with a T-shaped plate 2 through an installation mechanism, and the installation mechanism includes a screw thread Cover 19, bolt 20 and recessed hole 21, described wall body 1 is fixedly connected with threaded sleeve 19, has recessed hole 21 on the described T-shaped board-2, and bolt 20 passes through described recessed hole 21 and with described screw thread The sleeve 19 is threaded, and the recessed hole 21 needs to be explained. The port on one side of the recessed hole 21 close to the threaded sleeve 19 is smaller than the port on the other side, so one end of the bolt 20 can pass through the recessed hole 21 while the other end cannot;

[0046] The bottom of the side wall of the T-shaped plate 2 is provided with a groove 3, and the bottom of th...

Embodiment 2

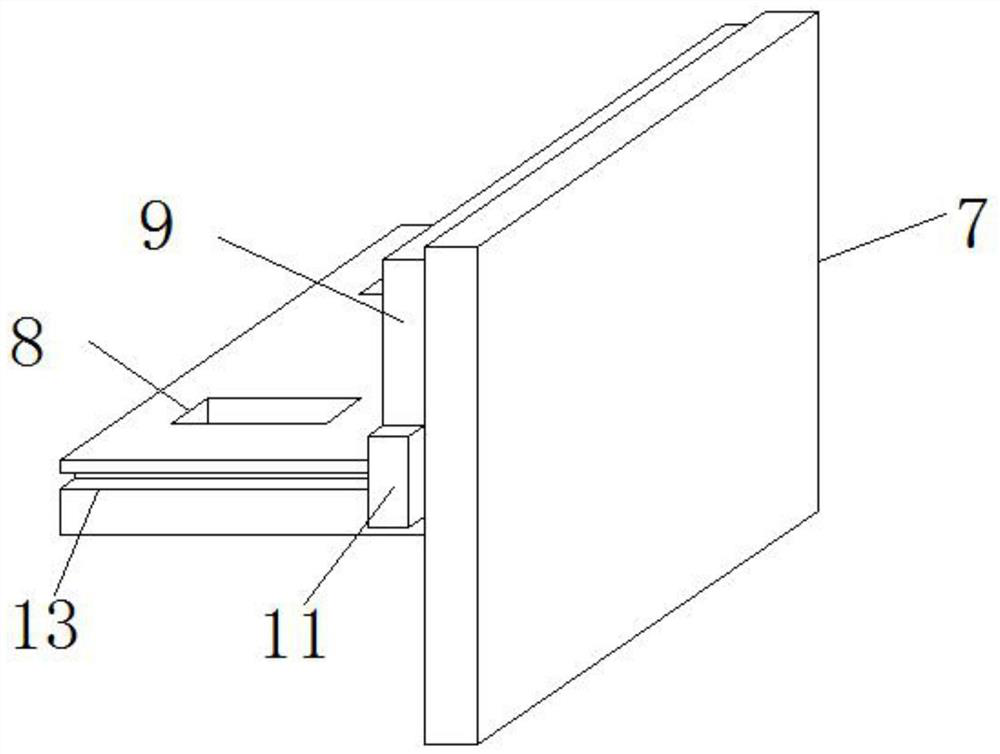

[0052] see Figure 9 , a supporting steel bar 41 is provided between the movable plate one 9 and the T-shaped plate two 7, and the periphery of the supporting steel bar 41 is arranged between the movable plate one 9 and the T-shaped plate two 7 Filling material 40, when the gap between movable plate one 9 and T-shaped plate two 7 is bigger, measure the spacing between movable plate one 9 and T-shaped plate two 7, cut out the supporting steel bar 41 of suitable length, and In order to avoid supporting steel bar 41 from damaging movable plate one 9 and T-shaped plate two 7, welding protective block at the port of supporting steel bar 41, then supporting steel bar 41 is placed between movable plate one 9 and T-shaped plate two 7, and then The filling material 40 is used for filling, and the filling material 40 may be a solid filling block, or a gelatinous building filling material mixture.

Embodiment 3

[0054] see Figure 10 , Filling material 40 is provided between the movable plate one 9 and the T-shaped plate two 7, when the gap between the movable plate one 9 and the T-shaped plate two 7 is small, there is no need to use the supporting steel bar 41, directly use the filling Fill the gap with the material 40, measure the width of the gap, and cut out the filling material 40 with a suitable size. At this time, the filling material 40 is a solid filling block, and then the filling material 40 is placed in the gap with an adhesive, together with the movable plate. 9 and T-shaped plate two 7 bonding.

[0055] According to an embodiment of the present invention, a method for installing a bracket for special-shaped wall construction is also provided.

[0056] Such as Figure 11 As shown, the installation method of the bracket for the special-shaped wall construction includes the following steps:

[0057] Step S101, determining the installation position of the bracket on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com