A tunnel lining with press-in mold pouring technology and its method for monitoring the pressure and fullness of the lining concrete

A concrete and lining technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of concrete void, incompact and full state without effective methods or means, so as to reduce the hidden danger of tunnel traffic operation and save manpower and financial resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

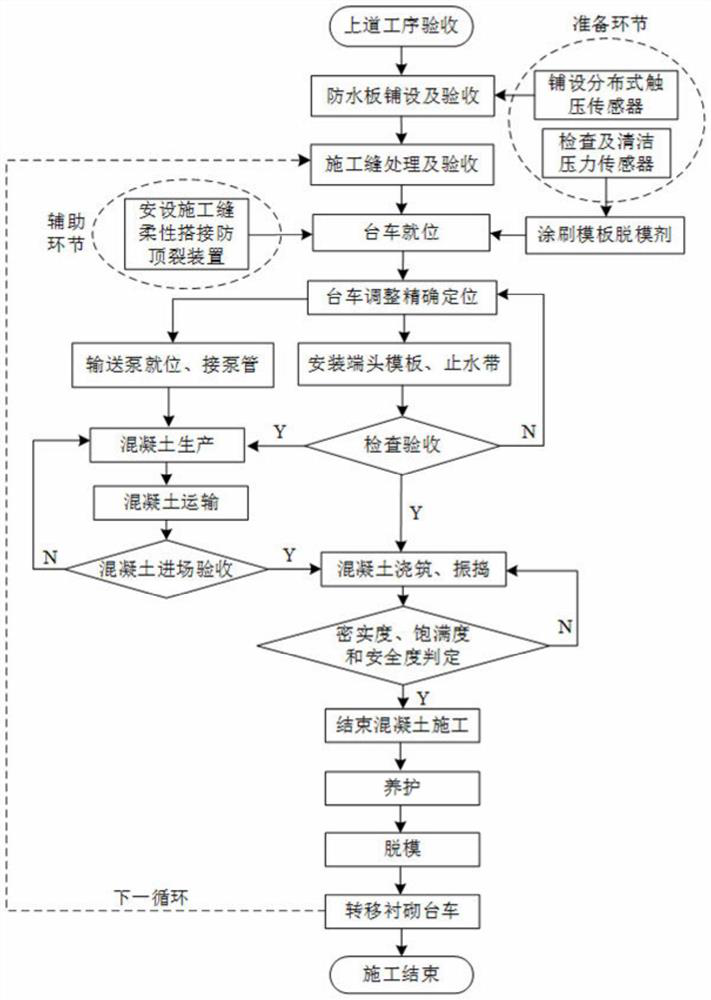

[0035] Such as figure 1 As shown, a tunnel lining vault pouring process includes the following steps: construction preparation, concrete filling construction and acceptance construction;

[0036] The construction preparation includes concrete production, concrete transportation and concrete entry acceptance. Waiting for the pump to be sent into the formwork, the concrete is produced first, and then transported to the construction site for acceptance. If the acceptance is qualified, the concrete is sent into the concrete by the delivery pump Filling construction, if the concrete is unqualified, it will be returned to the manufacturer;

[0037] The concrete filling construction includes the acceptance of the previous process. After the acceptance is passed, the initial support is carried out and the waterproof layer is laid on the lower surface of the concrete. After the inspection and acceptance, the construction joints of the tunnel lining wall and arch are treated, and the fo...

Embodiment 2

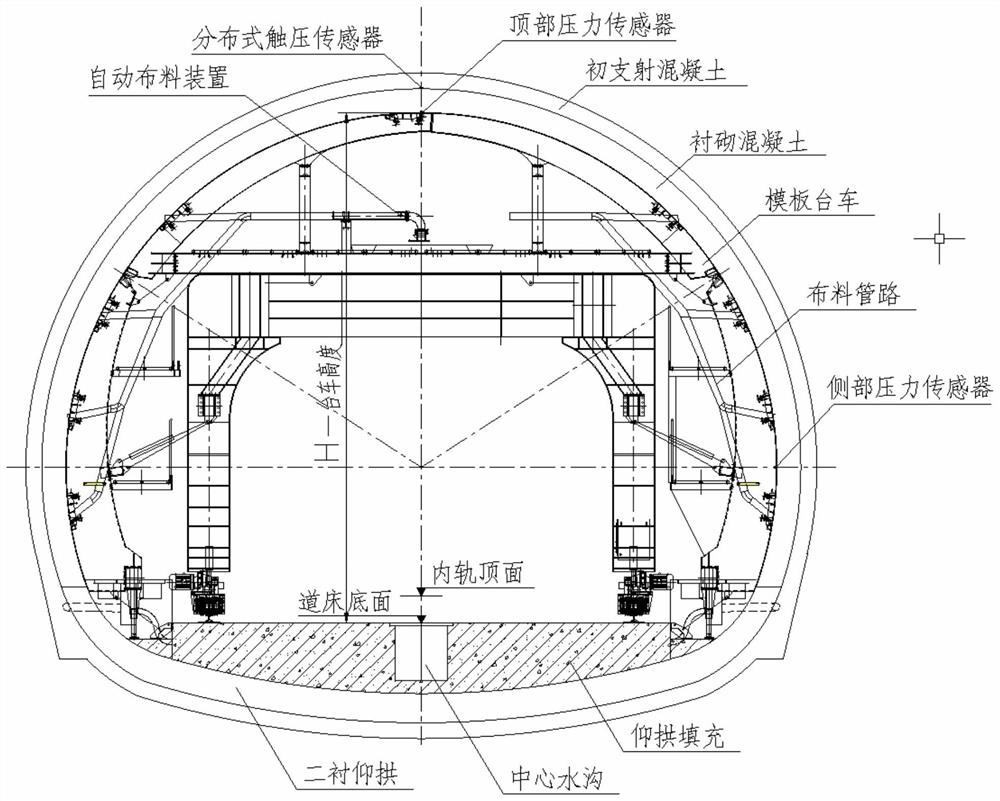

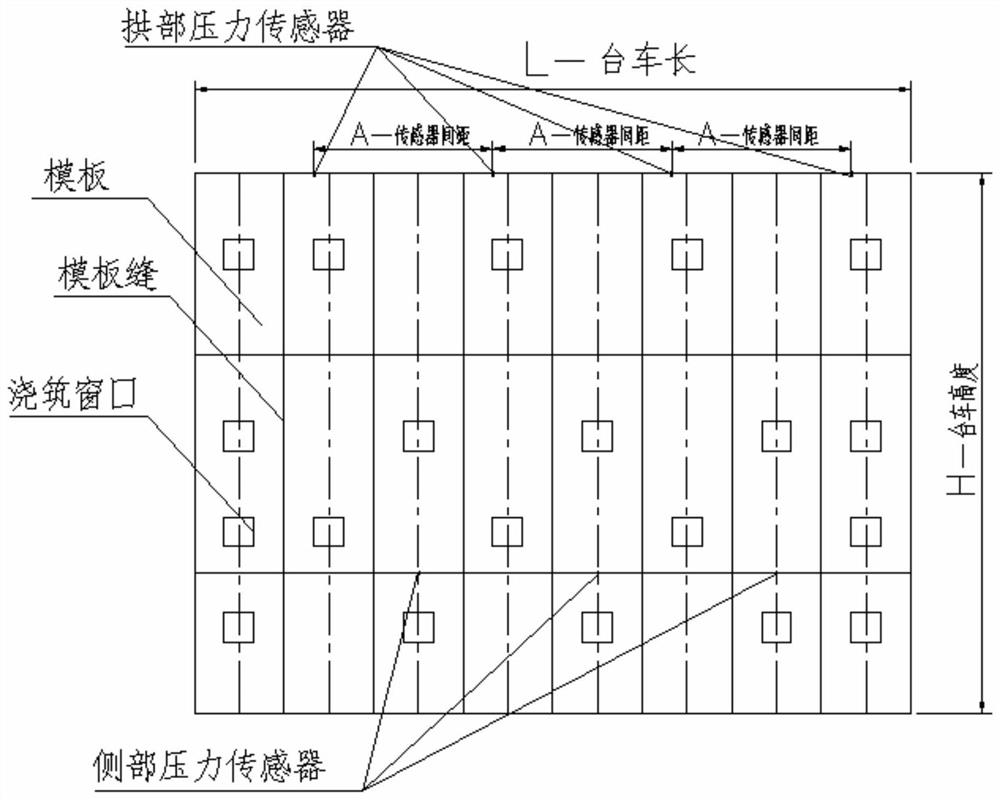

[0045] Such as figure 2 and Figure 3-1 , Figure 3-2 As shown, a method for monitoring the pressure and fullness of the tunnel lining vault includes the following steps: (1) laying distributed pressure sensors between the waterproof board and the primary support concrete to judge the relationship between the primary support concrete and the arch. The contact state of the roof, the upper surface of the vault formwork is laid with pressure sensors, which are used to judge the bottom pressure of the lining vault, and the lower surface of the vault formwork is equipped with several second pressure sensors, which are used to judge the concrete compactness of the lining vault; the formwork The length of the trolley is 12m, 2 pressure sensors are installed at the top 1m from both ends, and 2 pressure sensors are installed every 2.5m in the middle, a total of 4 pressure sensors; the side wall pressure sensors are arranged at a position about 3m away from the rail surface of the tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com