Liquid supply type gas compression device

A technology of gas compression and gas booster pumps, which is applied in mechanical equipment, liquid fuel engines, liquid variable displacement machinery, etc. It can solve the problems of increasing the difficulty of oil pipe disassembly and oil spillage, so as to ensure smoothness and improve sealing performance , Improve the effect of clamping width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

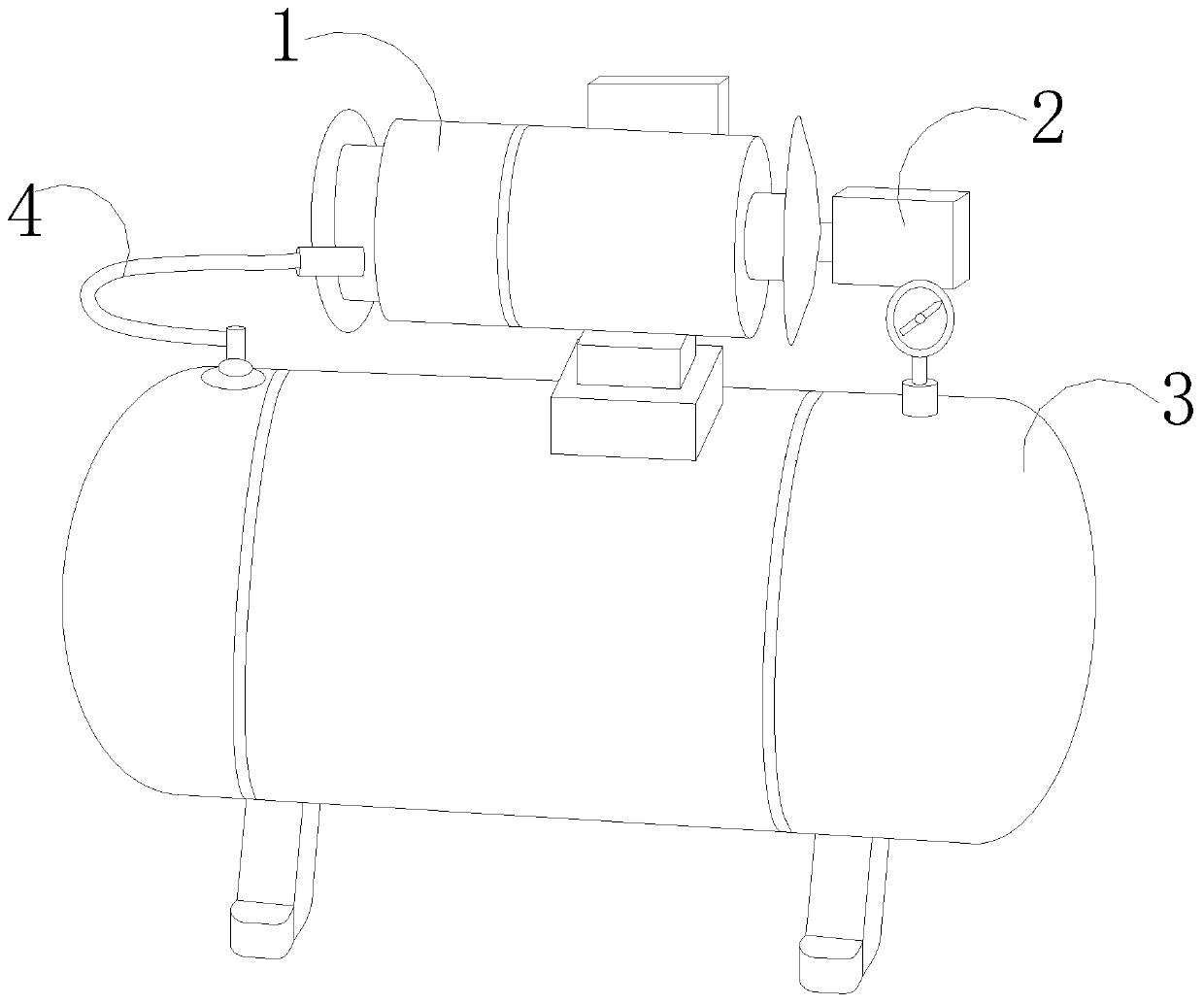

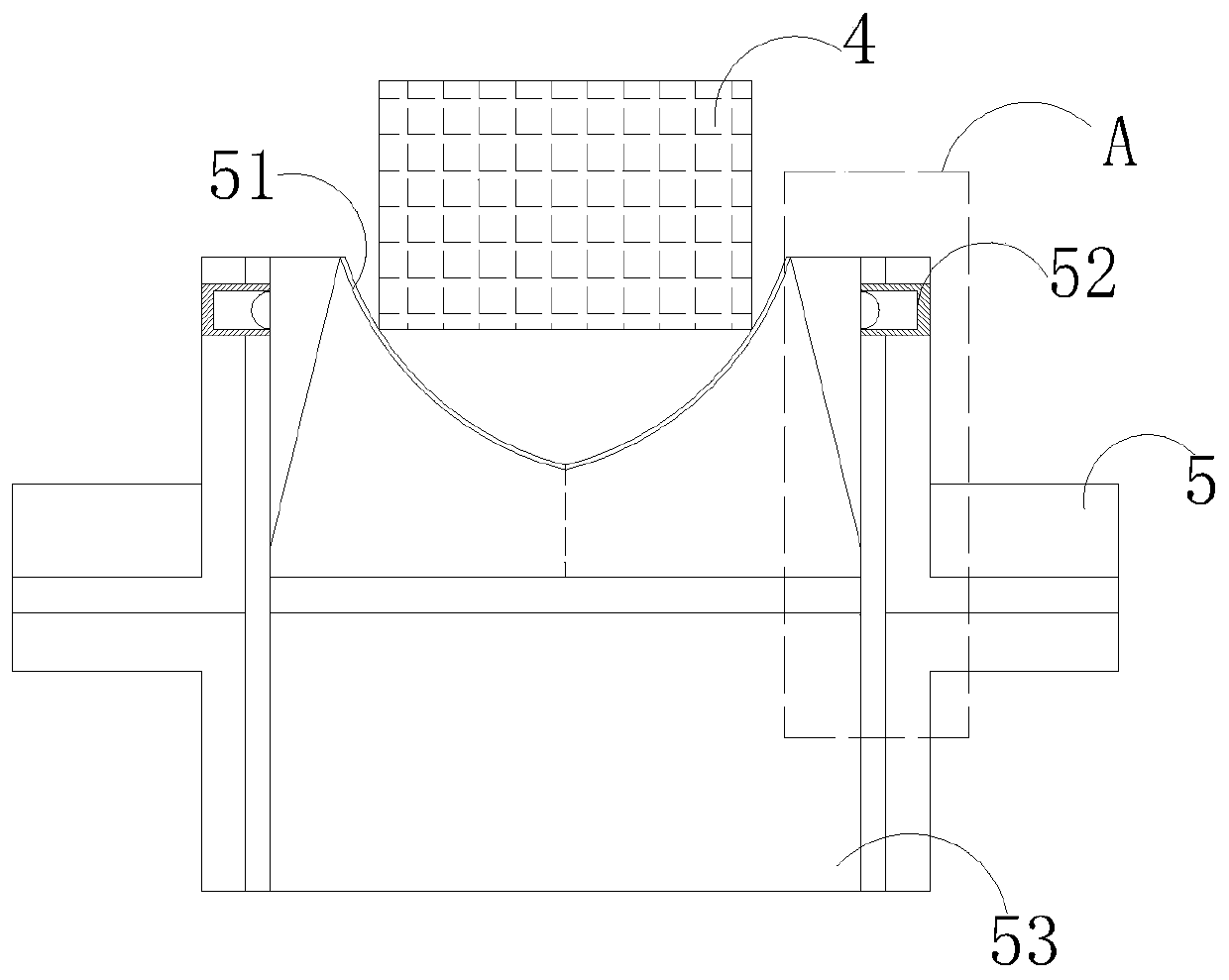

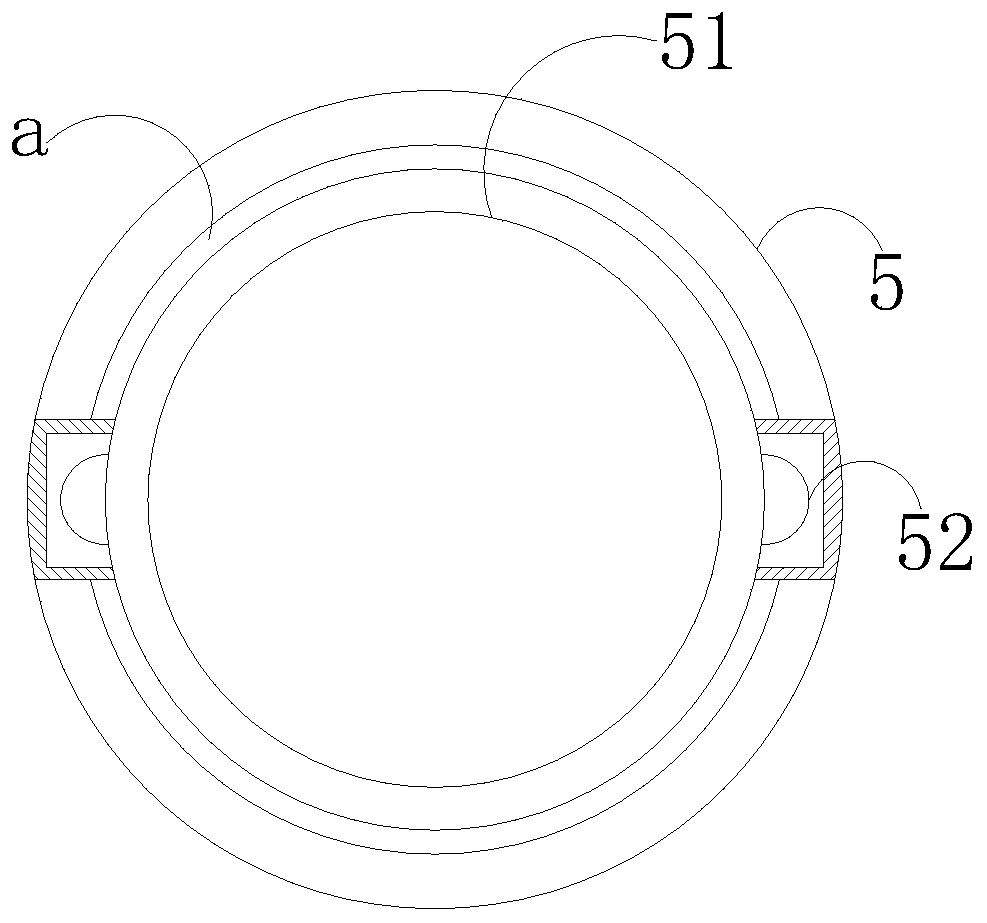

[0026] Such as Figure 1-Figure 4 , Figure 6 As shown, the present invention provides a liquid-supply gas compression equipment, the structure of which includes a hydraulic pump 1, an electric controller 2, a gas booster pump 3, an oil pipe 4, and an adapter 5. The hydraulic pump 1 is connected to the gas through the oil pipe 4 The booster pump 3 is connected, the hydraulic pump 1 and the gas booster pump 3 are both driven by the electric controller 2, and the adapters 5 are respectively installed at the interface between the oil pipe 4 and the gas booster pump 3 and the hydraulic pump 1, so that The adapter 5 is composed of a concave nozzle 51, a push block 52, and a cavity 53. Both sides of the concave nozzle 51 are connected with the push block 52, and are movably fitted inside the cavity 53 through the push block 52. The concave body nozzle 51 is in contact with the oil pipe 4, and the concave body nozzle 51 and the oil pipe 4 are movable in a horizontally advancing mann...

Embodiment 2

[0028] Such as Figure 4-Figure 5 As shown, based on Example 1, when the oil pipe is connected, the oil stain on the surface of the oil pipe is directly brought into the spacer to prevent oil spillage at the adapter. The bowl-shaped structure formed by the plate makes the connection of the oil pipe more precise, and the bowl-shaped structure is characterized by a port with a large upper part and a smaller port at the lower part. The larger port can better avoid the phenomenon of oil spillage in the adapter. The body tube port 51 is provided with a built-in plate 511, a spacer 512, a movable interface 513, a connecting rod 514, and a plate mouth decontamination mechanism 515. The spacer 512 is mechanically connected with the connecting rod 514 through a movable interface 513, and the plate mouth The decontamination mechanism 515 is located on the spacer 512 and is located inside the built-in board 511. The movable interface 513 is distributed on both sides, and a plate mouth de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com