Pump shaft axial force adaptive adjusting suspended magnetic pump

A self-adaptive adjustment and axial force technology, which is applied to components, pumps, pump devices, etc. of the pumping device used for elastic fluid, can solve the problem that the working efficiency of the magnetic pump cannot be further improved, and the stability of the axial rotation of the pump shaft Problems such as variation and high technical level of workers are required to achieve the effect of easy installation accuracy, quick and convenient assembly and replacement, and convenient and accurate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

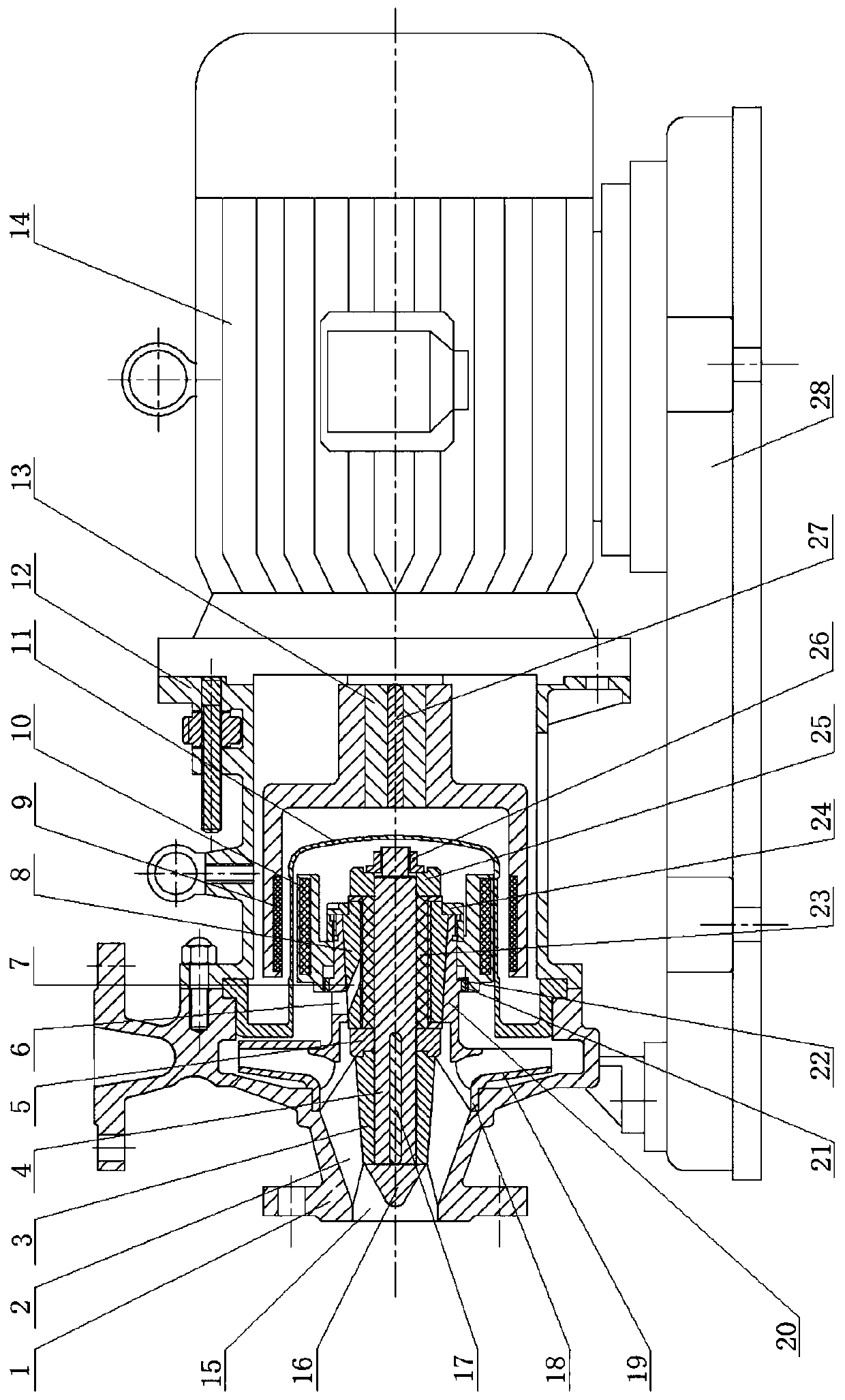

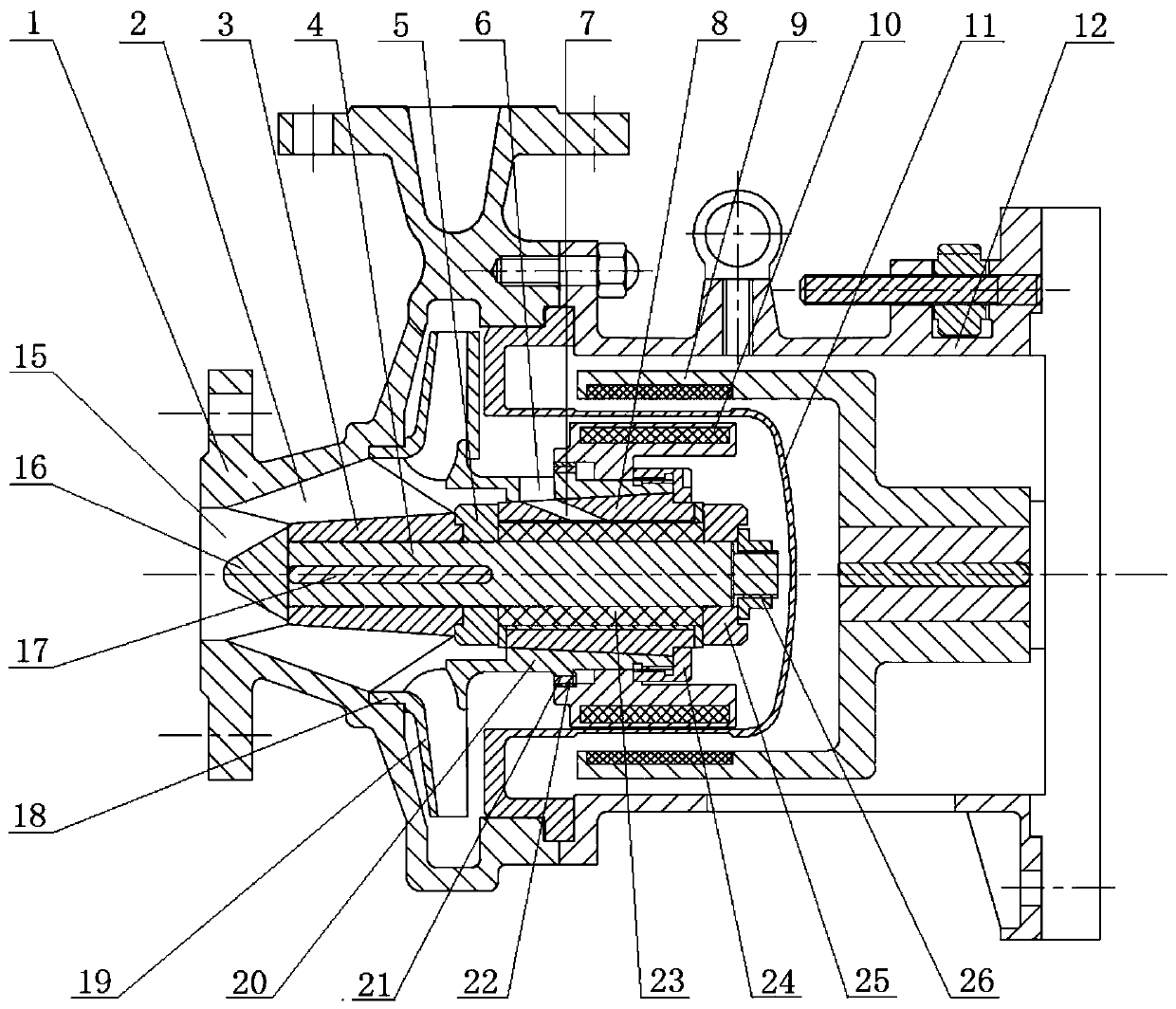

[0035] combine figure 1 and figure 2As shown, a suspension magnetic pump with self-adaptive adjustment of the axial force of the pump shaft in this embodiment includes a pump body 1, a pump shaft 4, an intermediate frame body 12, an impeller 19, an inner magnetic steel assembly 10, and an outer magnetic steel assembly 9 The pump body 1 and the intermediate frame body 12 are fixedly connected to form a pump chamber with the isolation sleeve 11, and the two can be fixedly connected by bolts. The isolation sleeve 11 is installed in the pump chamber to separate the pump chamber into an inner magnetic pump chamber and an outer magnetic pump chamber. There are two parts of the pump chamber, the main part of the spacer 11 is a U-shaped structure, and the opening of the spacer 11 is provided with a spacer mounting seat, which is fixed between the pump body 1 and the middle frame body 12. The spacer 11 is made of non-magnetic material, the outer magnetic steel assembly 9 is rotated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com