Strip mine high-step large-aperture buffer blasting method

A technology for large-aperture and open-pit mines, applied in blasting and other directions, can solve the problems of large receiving space, low pre-split blasting efficiency of small-aperture, and many types of mining rigs, so as to improve operational safety, reduce instability risks, and reduce The effect of single-hole charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

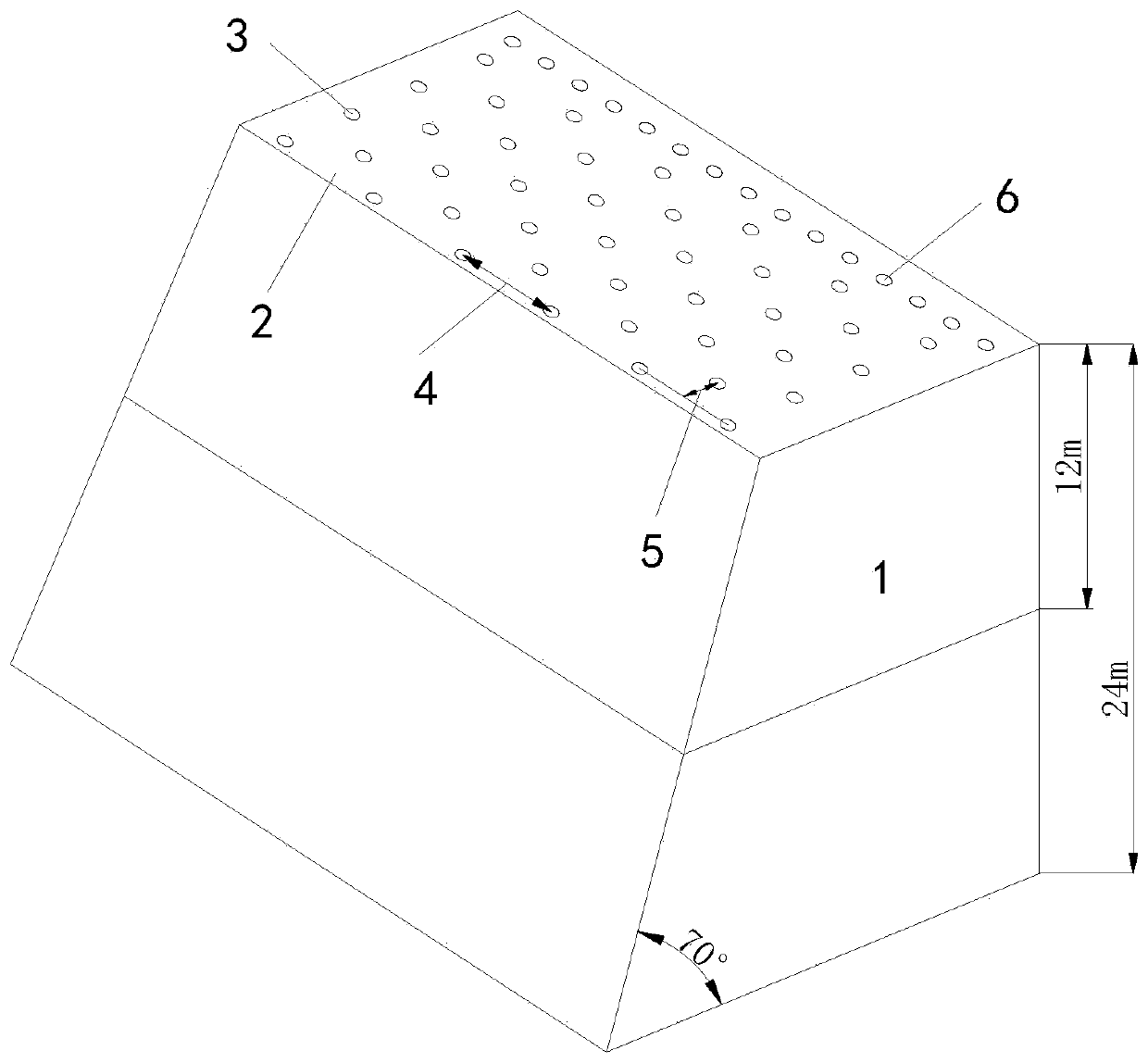

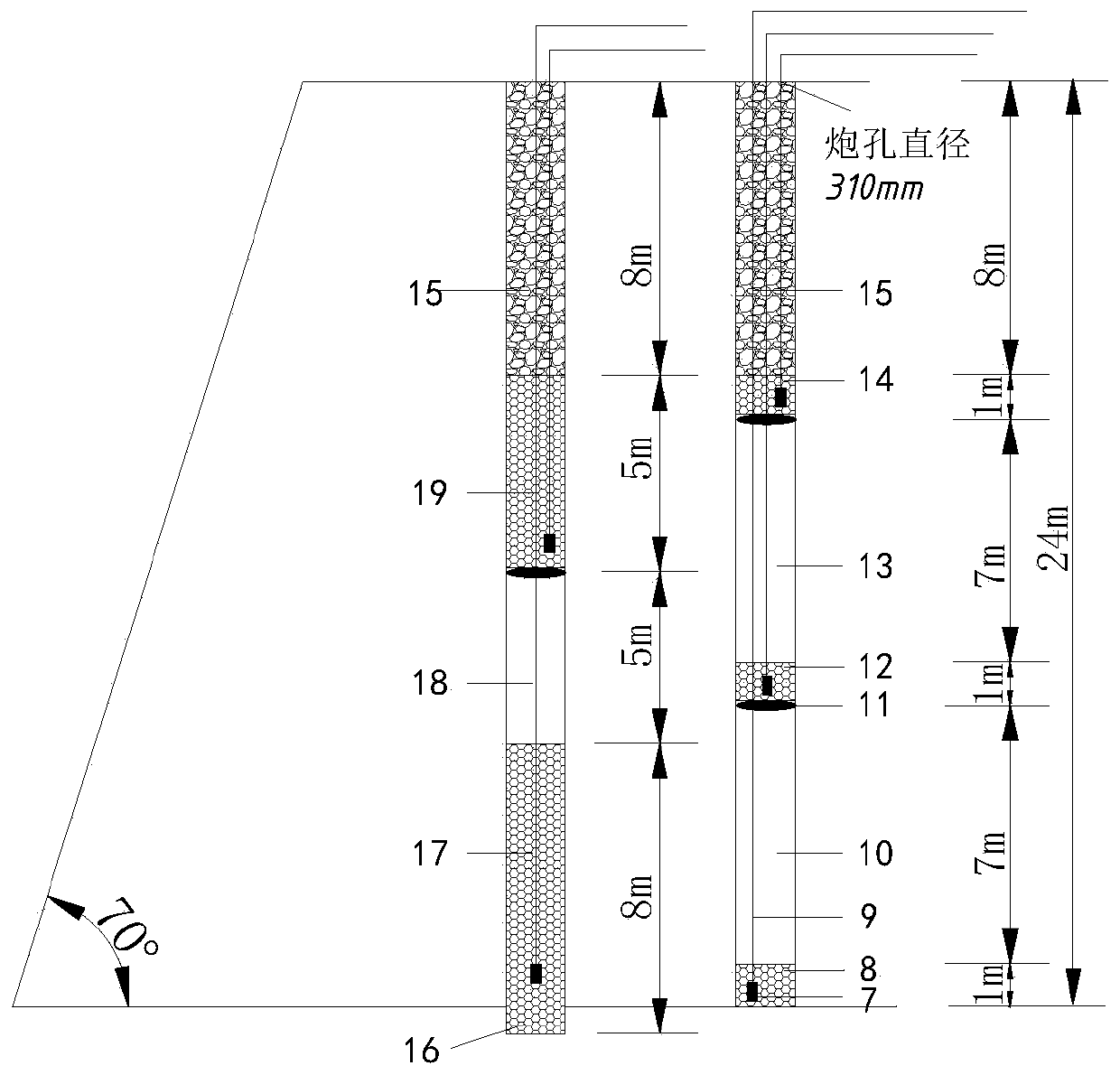

[0023] like figure 1 and 2 As shown, a buffer blasting method with high steps and large apertures in an open-pit mine, except for the last row of buffer holes 6 on the merged step 2 of the open-pit mine, the rest of the normal blast holes 3 are arranged in a triangular manner, and the hole network parameters are according to Row spacing 5×hole spacing 4=(5.0~5.5)m×(15~16)m, ultra-deep setting is 2~2.5m according to lithology, and the hole spacing of buffer hole 6 is 1 / 4 of that of normal hole 3 ~2 / 3, the buffer hole 6 is not set to be super deep; drill a 310mm large-diameter blast hole with a roller drill, and after the blast hole is accepted, the buffer hole 6 is divided into three stages from bottom to top with air intervals; normal blast holes 3. The charge is divided into two stages with air intervals, and all blastholes are filled and detonated by hole-by-hole detonation after connecting the wires. On the 24.0m high step of the merged section, the comprehensive technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com