Rolling bearing fault diagnosis method based on feature alignment convolutional neural network

A convolutional neural network and rolling bearing technology, which is applied in the field of rolling bearing fault diagnosis based on feature-aligned convolutional neural network, can solve the problems of convolutional neural network classification accuracy falling off a cliff, distortion, etc., to improve generalization performance, eliminate The effect of feature dislocation and model classification performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation steps.

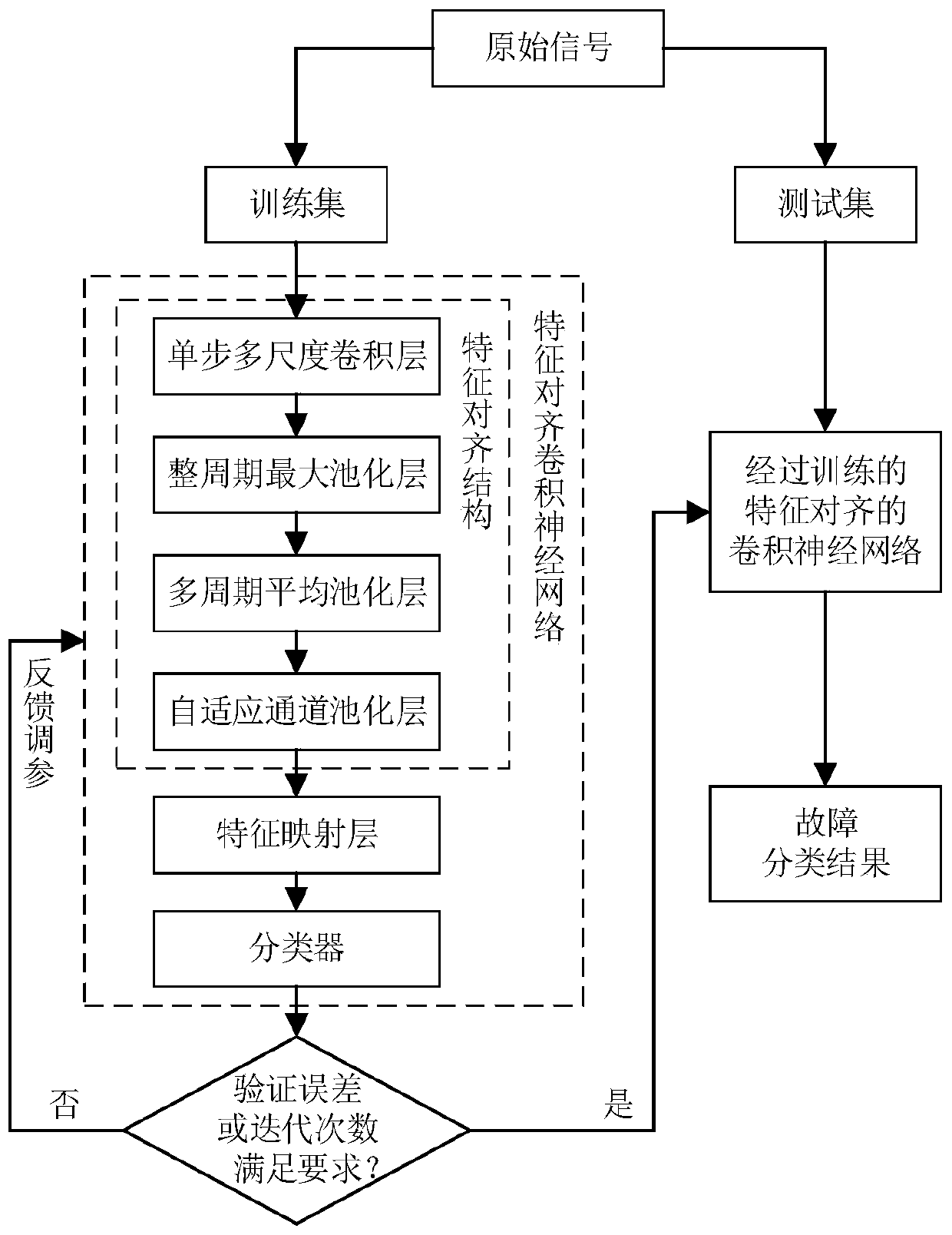

[0039] Such as figure 1 Shown is a flow chart of a rolling bearing fault diagnosis method based on a feature-aligned convolutional neural network. The specific implementation steps of the method are as follows:

[0040] (1) Obtain the acceleration signals of rolling bearings in various health states, make the signals into equal-length samples and assign health state labels;

[0041] (2) Divide the samples into a training set and a test set, and set sample weights for all samples in the training set according to the weight balance principle of each category;

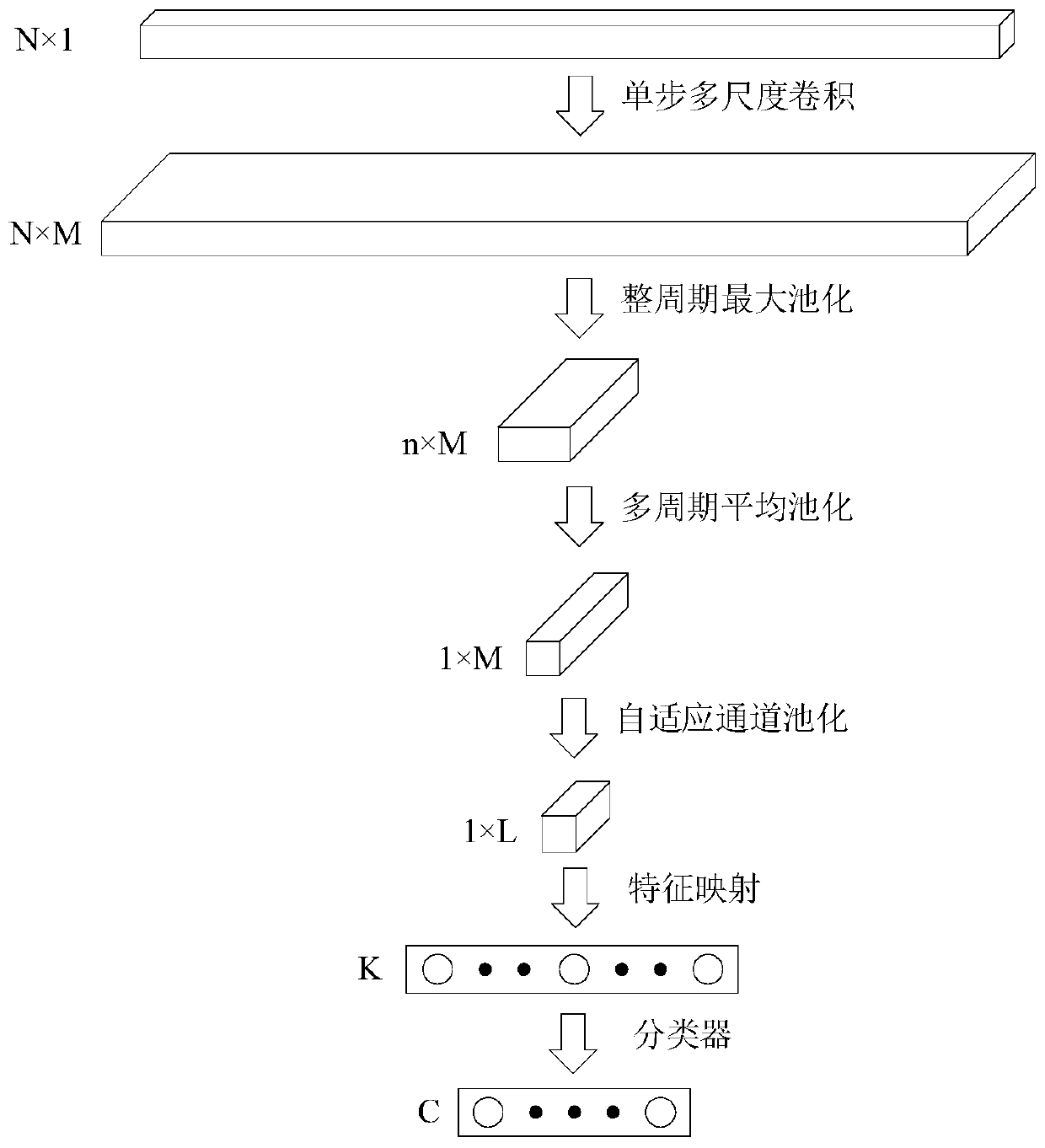

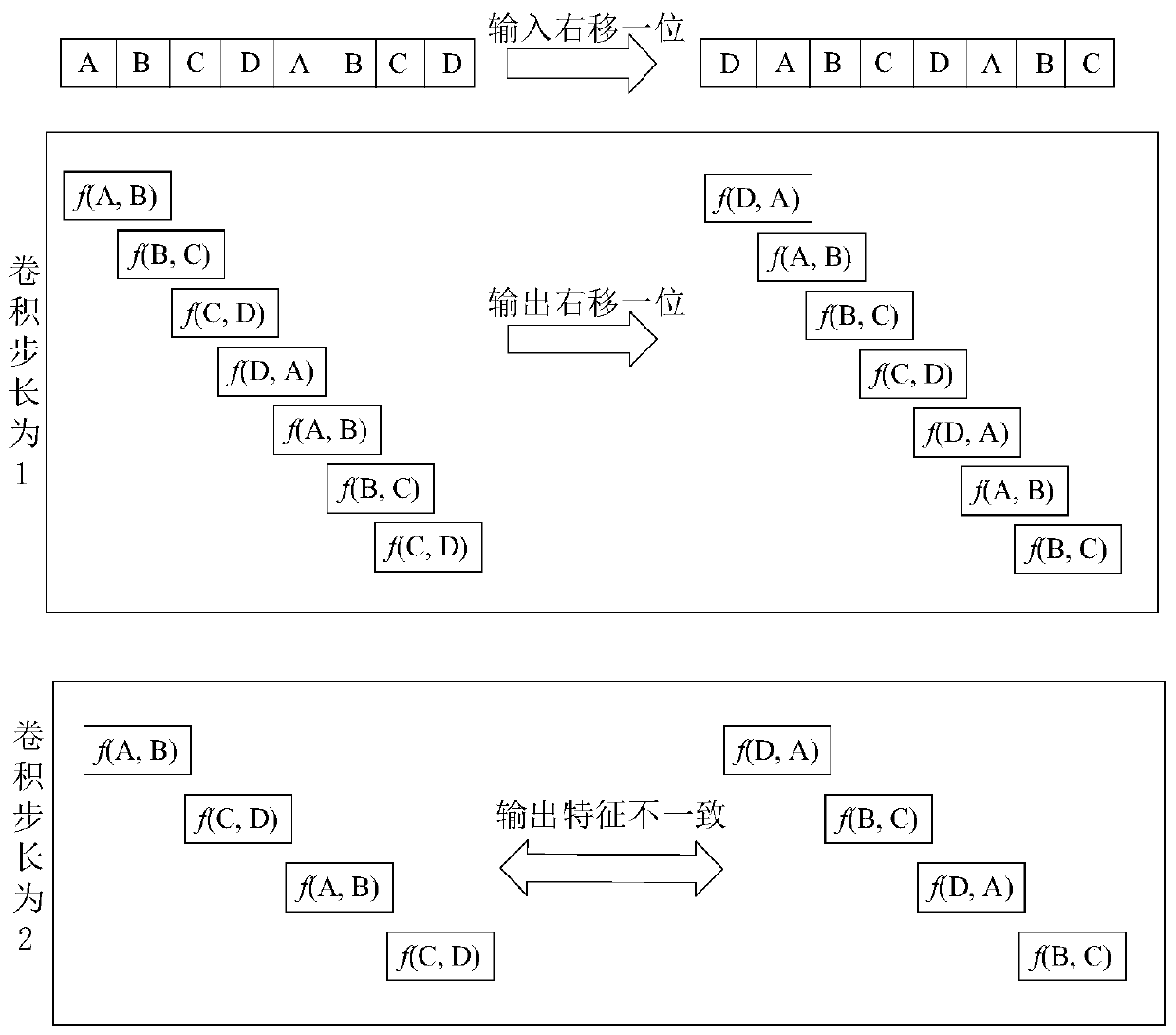

[0042] (3) Build a feature alignment convolutional neural network, including: a feature alignment structure, a feature mapping layer, and a classifier. The feature alignment structure includes a single-step multi-scale convolution layer and a full-cycle maximum pooling layer. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com