Display module with reflection structure and manufacturing method thereof

A display module and reflective structure technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of dark reflective brightness and low color saturation, and achieve enhanced reflective brightness, enhanced color saturation, and improved pressure resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

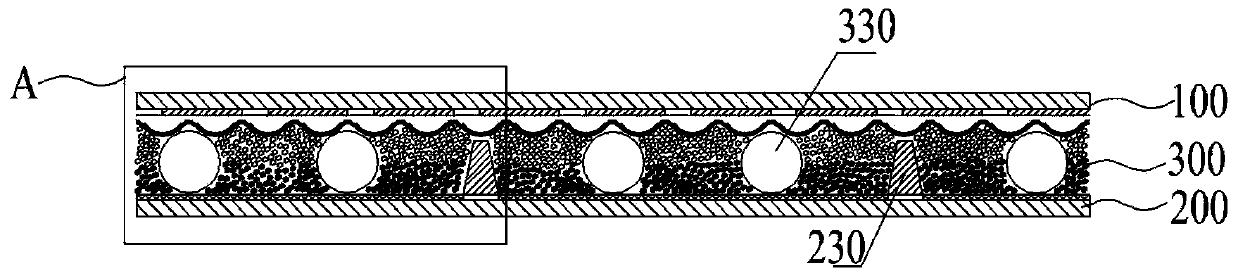

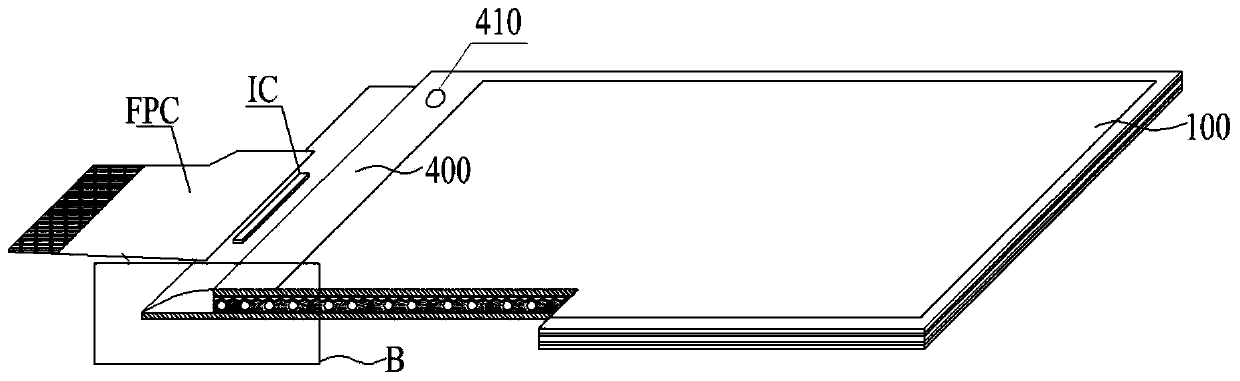

[0055] The first step: provide the lower substrate assembly 200 formed with the plasma barrier weir 230, place the lower substrate assembly 200 formed with the plasma barrier weir 230 on the dispensing platform, and dispense glue on the edge of the upper surface of the lower substrate assembly 200 to form a seal Plastic frame 400.

[0056] The lower substrate assembly 200 includes a lower panel 210 and a pixel electrode 220 formed on the lower panel 210; for example, the lower substrate assembly 200 is a TFT glass substrate, and the material of the lower panel 210 may be transparent glass.

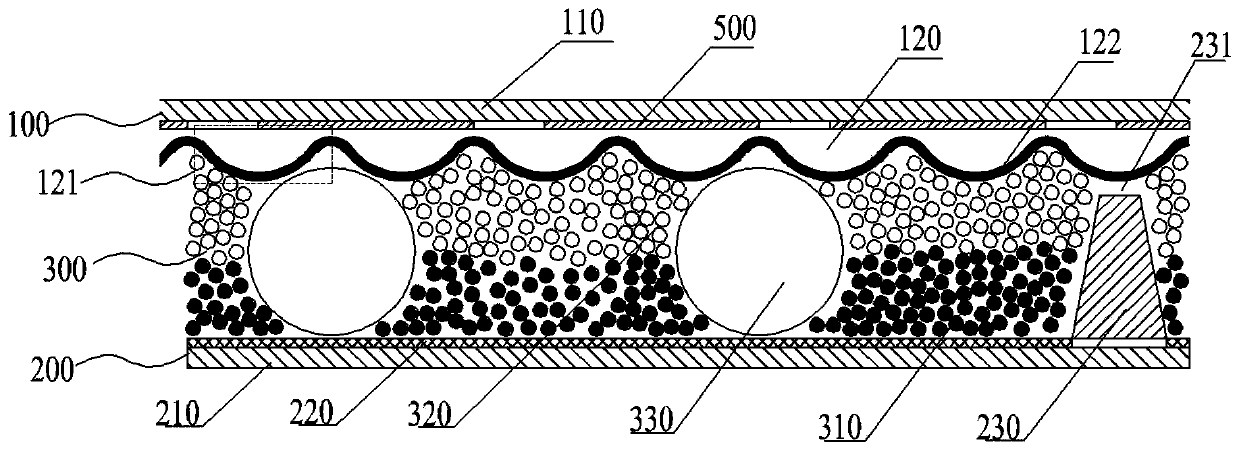

[0057] Step 2: Provide an upper panel 110 , and fabricate a reflective layer 120 on the lower surface of the upper panel 110 to form an upper substrate assembly 100 .

[0058] Exemplarily, the surface of the reflective layer 120 includes a plurality of arc surfaces, the reflective layer 120 can reflect light incident from the direction of the upper panel 110, the upper substrate assembly 1...

Embodiment 2

[0068] Step 1: Provide an upper panel 110 , and fabricate a reflective layer 120 on the lower surface of the upper panel 110 to form an upper substrate assembly 100 .

[0069] Exemplarily, the surface of the reflective layer 120 includes a plurality of arc surfaces, the reflective layer 120 can reflect light incident from the direction of the upper panel 110, the upper substrate assembly 100 is transparent, and the material of the upper panel 110 is transparent The material of the reflective layer 120 can be optical-grade acrylic resin, transparent polymer, transparent inorganic matter, transparent composite material and other materials, which have good reflection effect, and the optical-grade acrylic resin can increase the reflective brightness by 30%. and color saturation.

[0070] Step 2: Dispensing glue on the edge of the surface of the reflective layer 120 to form the sealing frame 400 .

[0071] Exemplarily, the upper substrate assembly 100 is placed on a dispensing pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com