Numerical prediction method for internal reflux and reflux vortex cavitation of vane pump

A numerical prediction and vane pump technology, applied in CAD numerical modeling, image data processing, design optimization/simulation, etc., can solve the problems of long design cycle and high design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

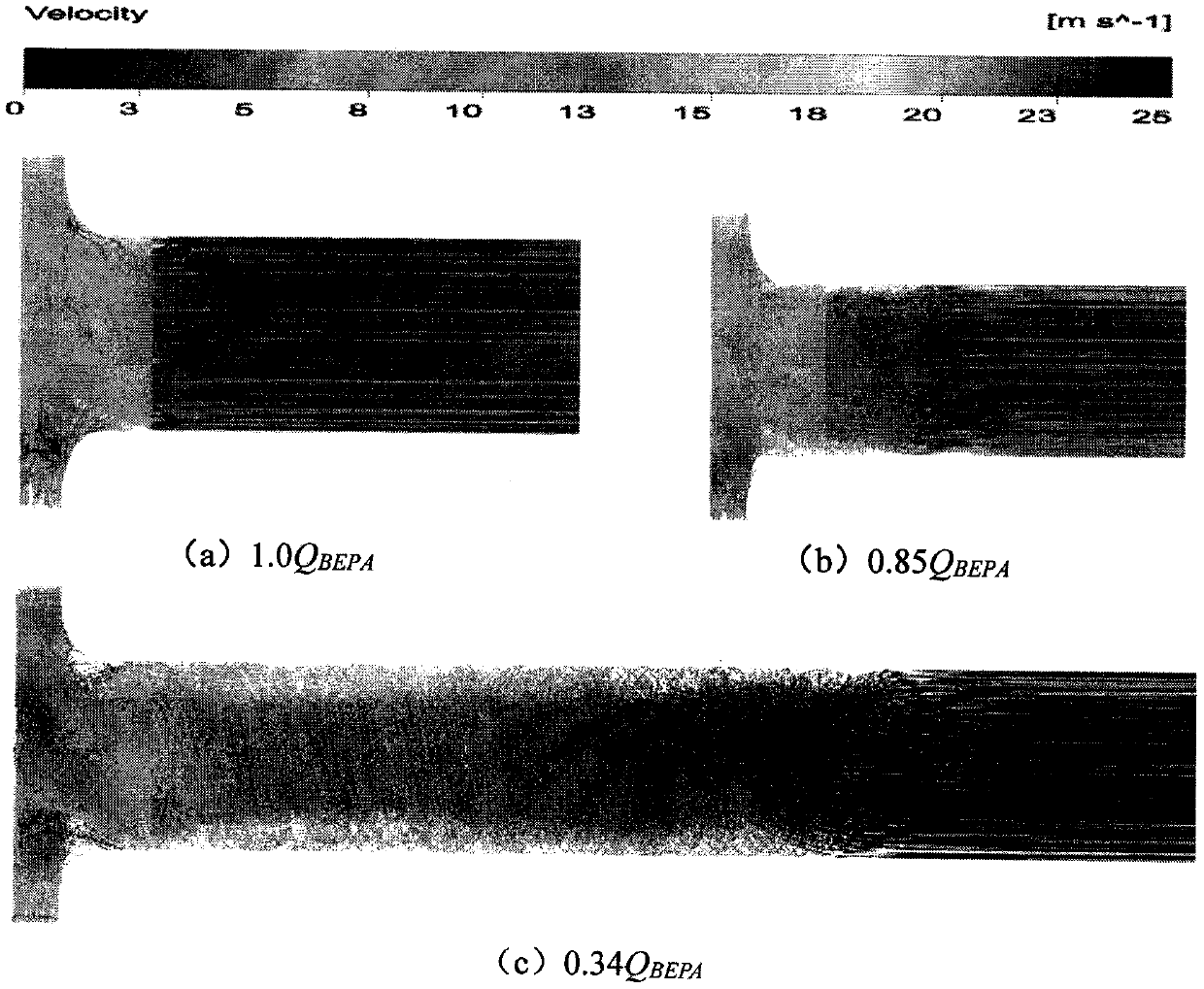

[0060] This embodiment takes a centrifugal pump as an example, its main design parameters: flow Q=94m 3 / h, head H=30m, speed n=2950rpmin, conveying medium is clean water, impeller inlet diameter D j =100mm, impeller outlet diameter D 2 =1669mm, the number of blades Z=7, the width of the impeller outlet b 2 = 21 mm. Build a closed test bench for the cavitation performance test of the centrifugal pump, and conduct the external characteristic test, cavitation performance test and pressure pulsation experiment of the centrifugal pump through the closed test bench, so as to obtain the external characteristics, cavitation performance and pressure pulsation of the centrifugal pump Test Results.

[0061] The numerical diagnosis method of the vane pump inlet backflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com