High-IP-protection-level voltage transformer capable of being used for gas-insulated high-voltage switch cabinet

A technology of voltage transformers and high-voltage switchgears, applied in the field of transformers, can solve the problems of enhanced safety functions of transformers, low protection level of transformers, unfavorable use, etc., and achieve the effect of simple structure, increased protection level, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

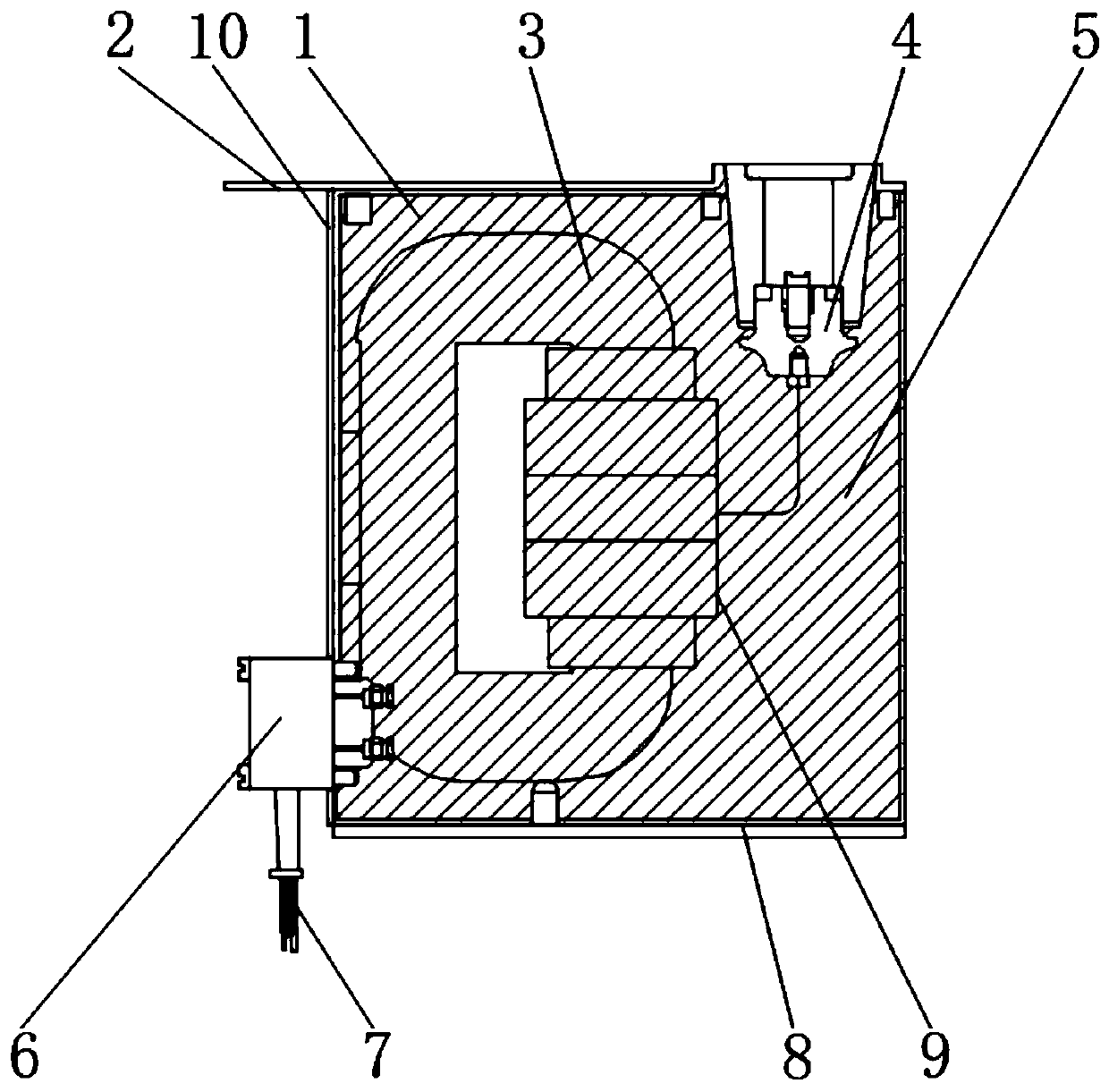

[0023] Embodiment one: if figure 1 As shown, the outer surface of the voltage transformer main body 1 is provided with epoxy resin 5, and the inside of the epoxy resin 5 is provided with a metal shielding net 10, and the voltage transformer main body 1, epoxy resin 5 and metal shielding net 10 are poured Sealed molding can increase the protection level, the protection level is as high as IP67, and the equipment can work normally under water for at least 30 minutes; after being immersed in water, it can be put into normal operation after drying, and at the same time, it can realize safe and touchable functions.

Embodiment 2

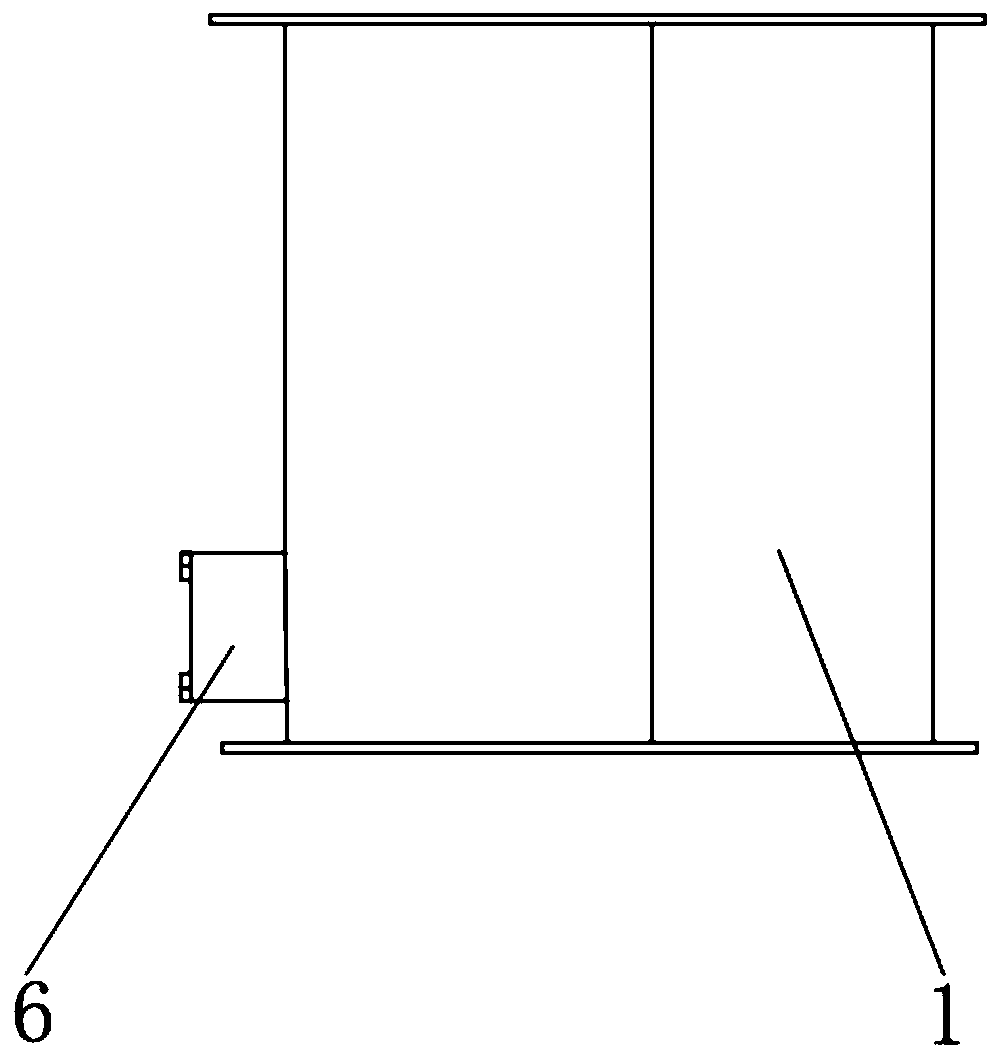

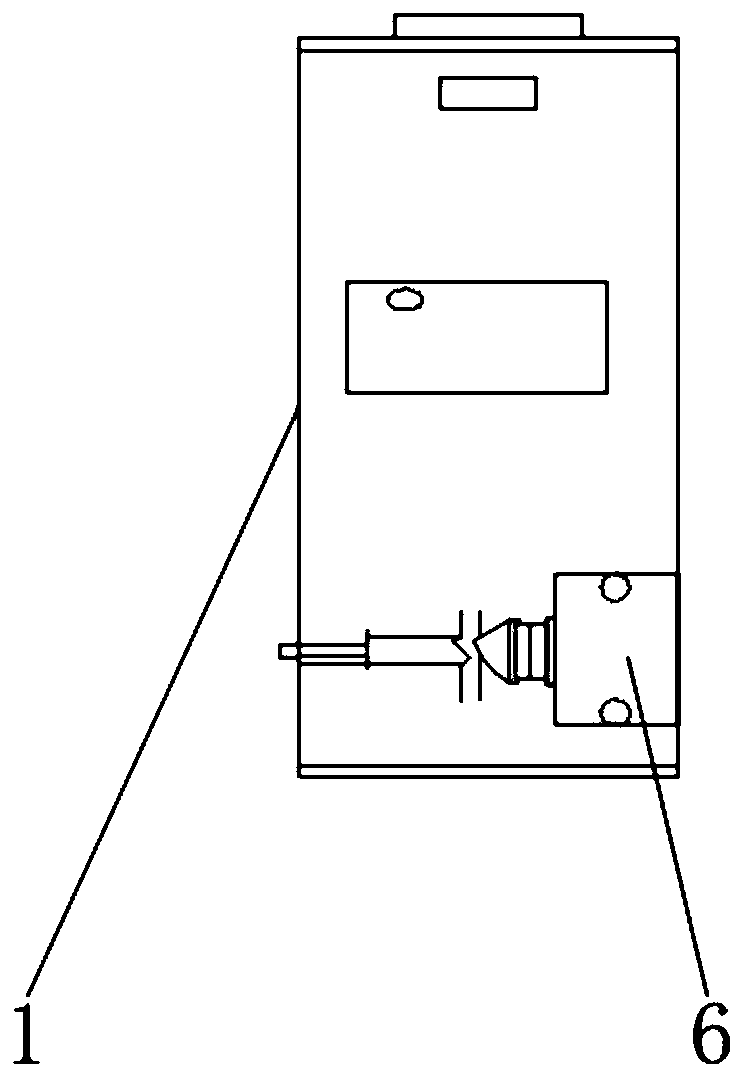

[0024] Embodiment two: if figure 1 As shown, a fixing screw is provided between the secondary junction box 6 and the voltage transformer main body 1, and one side outer surface of the secondary junction box 6 is fixedly connected with one side outer surface of the voltage transformer main body 1 through fixing screws, and the iron core 3. Pouring inside the epoxy resin 5, a connecting wire is provided between the voltage transformer main body 1 and the primary conductor 4, and one end of the voltage transformer main body 1 is electrically connected to one end of the primary conductor 4 through the connecting wire, and the voltage transformer main body 1 and the mounting aluminum plate 2 are provided with bolts, and the upper end of the voltage transformer main body 1 is fixedly connected with the lower end of the mounting aluminum plate 2 through bolts, which is more convenient for installation and disassembly, and the connection is more stable, and it is not easy to fall off, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com