Flavoring base material for soy sauce powder, preparation method and flavoring method

A technology of soy sauce powder and fragrance base, which is applied in the direction of food science, etc., can solve the problems of weakening flavor intensity, loss of flavor substances, and difficulty in presenting the flavor of soy sauce crude oil again, and achieve the effect of enhancing the flavor of soy sauce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

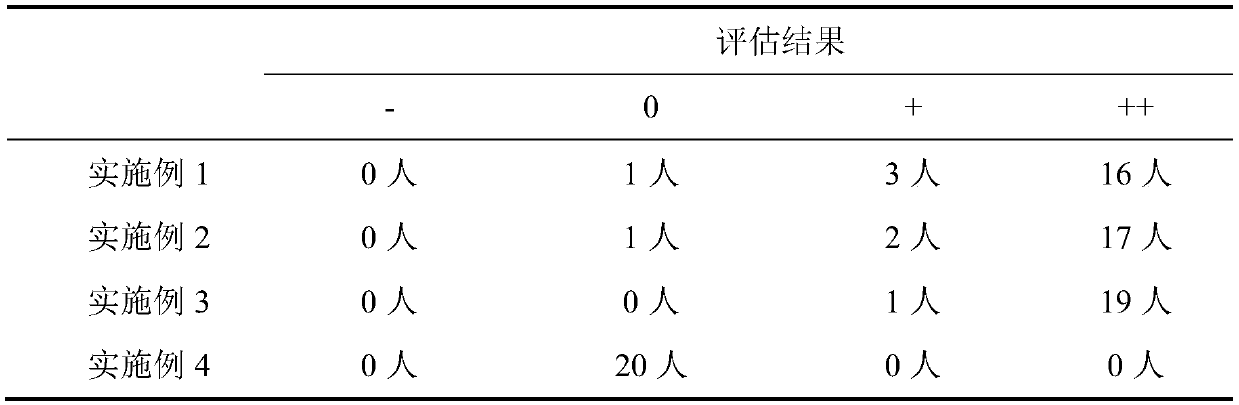

Embodiment 1

[0020] A flavoring method of soy sauce powder of the present invention comprises the following steps: 1) Allocate flavoring base material thermal reaction solution according to the following formula: 50 kg of brewed soy sauce, 3 kg of monosodium glutamate, 5 kg of L-alanine, 8 kg of xylose, and lysine 1kg, glucose 2kg, lactic acid 0.1kg, water 30.9kg; 2) Thermal reaction: Put the thermal reaction liquid of the flavoring base material into the reactor for reaction, control the thermal reaction conditions: 110°C, maintain the pressure in the reactor at 0.05-0.1MPa , the reaction time is 40min, and after the reaction, add water to the total mass of the reaction solution to 100kg to obtain the flavoring base material; 3) prepare the blended liquid containing 1000kg of dry material according to the existing conventional soy sauce powder formula, add 50kg of the above-mentioned flavoring base material, and Stir evenly and wait for the liquid to be sprayed; 4) Sterilization and spray ...

Embodiment 2

[0022] A method for increasing flavor of soy sauce powder of the present invention comprises the following steps: 1) deploying a thermal reaction solution of flavoring base material according to the following formula: 65.5 kg of brewed soy sauce, 10 kg of monosodium glutamate, 10 kg of L-alanine, 8 kg of xylose, and lysine 2kg of acid, 4kg of glucose, 0.5kg of lactic acid; 2) thermal reaction: put the thermal reaction solution of the flavoring base material into the reactor for reaction, and control the thermal reaction conditions: 110°C, maintain the pressure in the reactor at 0.05-0.1MPa, and the reaction time 40min, after the reaction, add water until the total mass of the reaction solution is 100kg to obtain the flavoring base material; 3) prepare a blended liquid containing 1000kg of dry material according to the existing conventional soy sauce powder formula, add 70kg of the above flavoring base material, and stir evenly, 4) Sterilization and spray drying: The liquid to b...

Embodiment 3

[0024] A flavoring method for soy sauce powder of the present invention comprises the following steps: 1) deploying a flavoring base thermal reaction solution according to the following formula: 70 kg of brewed soy sauce, 5.5 kg of monosodium glutamate, 6 kg of L-alanine, 10 kg of xylose, and lysine 3kg of acid, 5kg of glucose, 0.5kg of lactic acid; 2) thermal reaction: put the thermal reaction solution of the flavoring base material into the reactor for reaction, and control the thermal reaction conditions: 110°C, maintain the pressure in the reactor at 0.05-0.1MPa, and the reaction time 40min, after the reaction, add water until the total mass of the reaction solution is 100kg to obtain the flavoring base material; 3) prepare a blended liquid containing 1000kg of dry material according to the existing conventional soy sauce powder formula, add the above-mentioned flavoring base material 100kg, and stir evenly, 4) Sterilization and spray drying: The liquid to be sprayed is ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com